Wet curing involves submerging meat in a brine solution to enhance flavor and preserve moisture, resulting in a tender texture and extended shelf life. Koji curing uses the natural enzymes from Aspergillus oryzae mold to break down proteins and fats, intensifying umami flavors and creating a unique savory profile. Both methods improve meat's taste and preservation, but koji curing offers a distinctive depth of flavor driven by enzymatic fermentation.

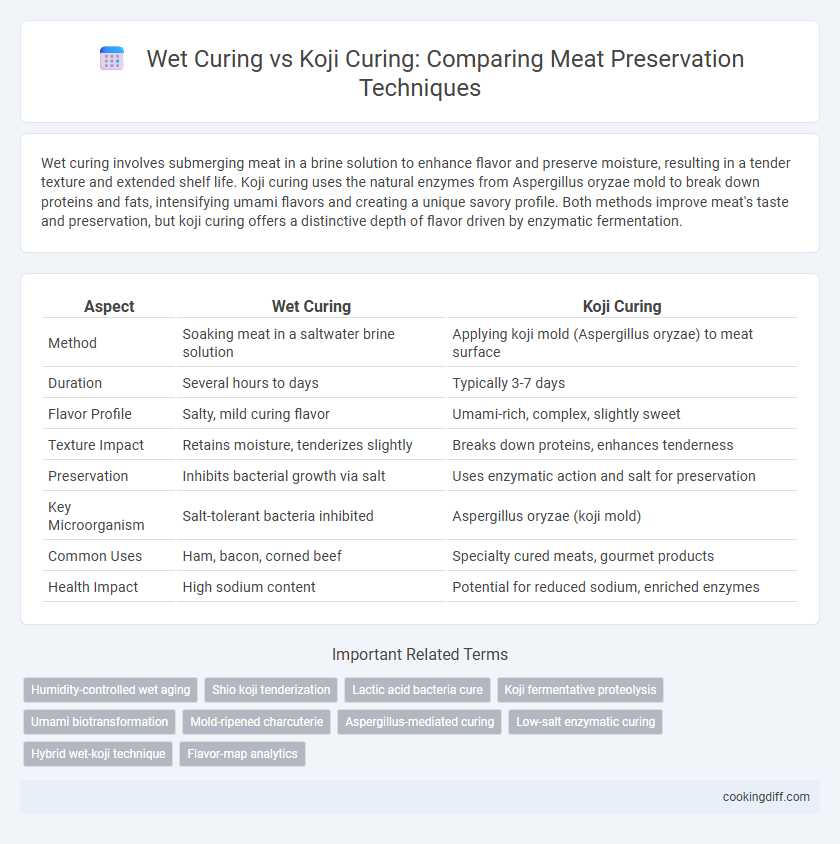

Table of Comparison

| Aspect | Wet Curing | Koji Curing |

|---|---|---|

| Method | Soaking meat in a saltwater brine solution | Applying koji mold (Aspergillus oryzae) to meat surface |

| Duration | Several hours to days | Typically 3-7 days |

| Flavor Profile | Salty, mild curing flavor | Umami-rich, complex, slightly sweet |

| Texture Impact | Retains moisture, tenderizes slightly | Breaks down proteins, enhances tenderness |

| Preservation | Inhibits bacterial growth via salt | Uses enzymatic action and salt for preservation |

| Key Microorganism | Salt-tolerant bacteria inhibited | Aspergillus oryzae (koji mold) |

| Common Uses | Ham, bacon, corned beef | Specialty cured meats, gourmet products |

| Health Impact | High sodium content | Potential for reduced sodium, enriched enzymes |

Introduction to Meat Curing Methods

Wet curing involves immersing meat in a brine solution containing salt, sugar, and curing agents to enhance flavor, moisture retention, and preservation. Koji curing utilizes the enzyme-rich mold Aspergillus oryzae, which breaks down proteins and fats, imparting unique umami flavors and tenderizing the meat. Both methods offer distinct advantages, with wet curing focusing on moisture and salt penetration, while koji curing emphasizes enzymatic transformation and flavor complexity.

What Is Wet Curing?

Wet curing, also known as brining, involves submerging meat in a saltwater solution infused with various spices and curing agents to enhance flavor and tenderness. This method allows the meat to absorb moisture and curing ingredients evenly over time, resulting in a juicier texture compared to dry curing.

Koji curing utilizes fermented rice mold to enzymatically break down proteins and fats, creating a unique umami flavor and tender texture without submersion in liquid. Wet curing remains the preferred technique for many because it is straightforward and effective for a wide range of meats, including ham, bacon, and poultry.

Understanding Koji Curing

Koji curing utilizes Aspergillus oryzae mold to enzymatically break down proteins and fats in meat, enhancing umami and tenderness without relying on salt. This fermentation-based method differs from traditional wet curing, which primarily uses brine solutions to preserve and flavor meat through salt and nitrates.

Understanding koji curing requires recognizing how the enzymes produced by koji accelerate flavor development and tenderization naturally over several days. The mold's protease and lipase enzymes transform complex proteins and fats into savory amino acids and fatty acids, resulting in a distinctive depth of flavor. Koji curing also reduces the need for added salt, offering a healthier alternative to conventional wet curing techniques.

Ingredients and Process Comparison

Wet curing involves submerging meat in a brine solution consisting mainly of water, salt, sugar, and nitrates for preservation and flavor enhancement. Koji curing uses rice mold (Aspergillus oryzae) enzymes to tenderize and ferment the meat, relying on koji spores as the primary ingredient rather than traditional brine.

- Ingredients in Wet Curing - Combines water, salt, sugar, and curing agents to infuse meat with moisture and regulate bacterial growth.

- Ingredients in Koji Curing - Utilizes koji rice culture rich in proteolytic and amylolytic enzymes to break down proteins and develop umami flavors.

- Process Differences - Wet curing requires soaking meat for days to weeks in brine, whereas koji curing involves coating meat with koji spores and fermenting at controlled temperatures for enzymatic action.

Flavor Profiles of Wet-Cured vs Koji-Cured Meats

Wet curing infuses meat with a moist, salty flavor, enhancing juiciness and preserving a classic cured taste. Koji curing introduces umami-rich enzymatic activity, creating complex, savory, and slightly sweet flavor profiles unique to fermented foods.

- Wet curing enhances moisture retention - Salt brines penetrate meat fibers, maintaining tenderness and juiciness.

- Koji curing develops umami depth - Aspergillus oryzae enzymes break down proteins and fats, intensifying savory notes.

- Flavor complexity differs significantly - Wet curing offers straightforward saltiness while koji curing produces nuanced, fermented flavors.

Texture Differences: Wet Cure vs Koji Cure

Wet curing imparts a moist, tender texture to meat by infusing it with a saline solution, which helps retain water during cooking. This method results in a uniformly soft and succulent bite, ideal for cuts requiring juiciness.

Koji curing, utilizing Aspergillus oryzae enzymes, breaks down proteins and fats, creating a complex, firm texture with a subtle umami flavor. The enzymatic activity in koji cure enhances meat tenderness while adding a unique depth and chewiness not found in wet curing.

Safety Considerations in Each Method

How do safety considerations differ between wet curing and koji curing for meat? Wet curing uses brine solutions that inhibit bacterial growth through high salt concentrations, reducing the risk of pathogens. Koji curing relies on mold enzymes to ferment and tenderize meat, requiring careful control of temperature and humidity to prevent spoilage and harmful microbial contamination.

Time and Equipment Needed

| Wet curing | Requires immersion of meat in a saltwater brine, typically taking 1 to 2 weeks depending on meat thickness. |

| Koji curing | Involves applying koji mold to meat's surface, accelerating curing to 3 to 5 days while requiring controlled humidity and temperature equipment. |

| Equipment comparison | Wet curing needs basic containers and refrigeration; koji curing requires specialized incubation chambers to maintain optimal conditions for mold growth. |

Culinary Applications and Recipe Ideas

Wet curing uses a saltwater brine that penetrates meat, ideal for bacon and hams, enhancing moisture retention and tenderness. Koji curing employs fermented rice mold enzymes, imparting umami and tenderizing meat uniquely, perfect for premium steaks and dry-cured charcuterie.

- Wet curing enhances juiciness - Its brine solution preserves moisture, making it suitable for juicy dishes like corned beef and poultry.

- Koji curing develops complex flavors - Enzymatic action breaks down proteins and fats, resulting in savory depth for gourmet recipes.

- Wet curing suits larger cuts - The method evenly infuses salt in substantial meat portions for consistent seasoning.

Cooks prefer wet curing for traditional recipes and koji curing for innovative culinary experiences that highlight umami-rich flavor profiles.

Related Important Terms

Humidity-controlled wet aging

Humidity-controlled wet aging maintains precise moisture levels and temperature to enhance enzymatic breakdown and tenderness in meat, minimizing weight loss and bacterial growth. Compared to koji curing, wet curing emphasizes moisture retention and natural enzymatic activity without introducing fungal cultures, resulting in a juicier texture and cleaner flavor profile.

Shio koji tenderization

Shio koji curing utilizes the enzymatic activity of Aspergillus oryzae to break down proteins and fats in meat, resulting in enhanced tenderness and umami flavor compared to traditional wet curing methods. This fermentation process not only tenderizes the meat more effectively but also imparts unique savory complexity without the need for excessive salt.

Lactic acid bacteria cure

Wet curing employs saline solutions infused with lactic acid bacteria to enhance meat preservation by promoting acidification that inhibits spoilage organisms, resulting in improved texture and flavor development. Koji curing utilizes Aspergillus oryzae-derived enzymes alongside lactic acid bacteria to ferment proteins and sugars, accelerating tenderization and imparting umami-rich profiles distinct from traditional wet curing methods.

Koji fermentative proteolysis

Koji curing utilizes Aspergillus oryzae enzymes to induce fermentative proteolysis, breaking down muscle proteins into peptides and amino acids that enhance meat flavor and tenderness more naturally than wet curing. This enzymatic process accelerates maturation while reducing the reliance on high salt concentrations, promoting a healthier and more umami-rich product.

Umami biotransformation

Wet curing involves soaking meat in a saltwater brine that facilitates enzymatic breakdown and enhances umami through the release of amino acids like glutamate, while koji curing employs Aspergillus oryzae fermentation to intensify umami by producing proteolytic enzymes that convert proteins into savory peptides and free amino acids. The biotransformation in koji curing results in a deeper, more complex umami profile compared to the simpler amino acid enhancement seen in wet curing.

Mold-ripened charcuterie

Wet curing uses brine solutions to infuse meat with salt and flavor quickly, while koji curing employs Aspergillus oryzae molds to enzymatically break down proteins and fats, enhancing umami and developing complex flavors. In mold-ripened charcuterie, koji curing promotes natural fermentation and tenderization, creating distinct aromatic profiles and a delicate texture that wet curing cannot replicate.

Aspergillus-mediated curing

Wet curing relies on brine solutions to penetrate meat, utilizing salt and nitrates to preserve and flavor, whereas koji curing employs Aspergillus oryzae to enzymatically break down proteins and fats, enhancing umami and tenderness through natural fermentation. Aspergillus-mediated curing offers a unique biochemical process that produces amino acids and peptides, resulting in improved flavor complexity and shelf-life without the need for conventional chemical additives.

Low-salt enzymatic curing

Low-salt enzymatic curing using koji, a fermentation starter rich in proteolytic enzymes, enhances meat tenderness and flavor without the high sodium content typical of traditional wet curing. Wet curing relies on salt and water brines to preserve meat, but koji curing accelerates protein breakdown and umami development through enzymatic activity, offering a healthier alternative for flavor-rich cured meats.

Hybrid wet-koji technique

Hybrid wet-koji curing combines the moisture retention and preservation benefits of traditional wet curing with the enzymatic tenderizing and flavor-enhancing properties of koji fungi, resulting in meat that is both deeply infused and tenderized. This method optimizes fermentation while maintaining juiciness, producing consistently flavorful and richly textured meat products.

Wet curing vs koji curing for meat. Infographic

cookingdiff.com

cookingdiff.com