Smoke curing imparts a rich, smoky flavor and preserves food by introducing phenolic compounds, enhancing depth but sometimes masking subtle umami notes. Koji application amplifies umami through enzymatic breakdown of proteins into amino acids like glutamate, intensifying savory taste without overpowering the original flavors. Combining both methods can balance robust smokiness with heightened umami complexity for a unique sensory experience.

Table of Comparison

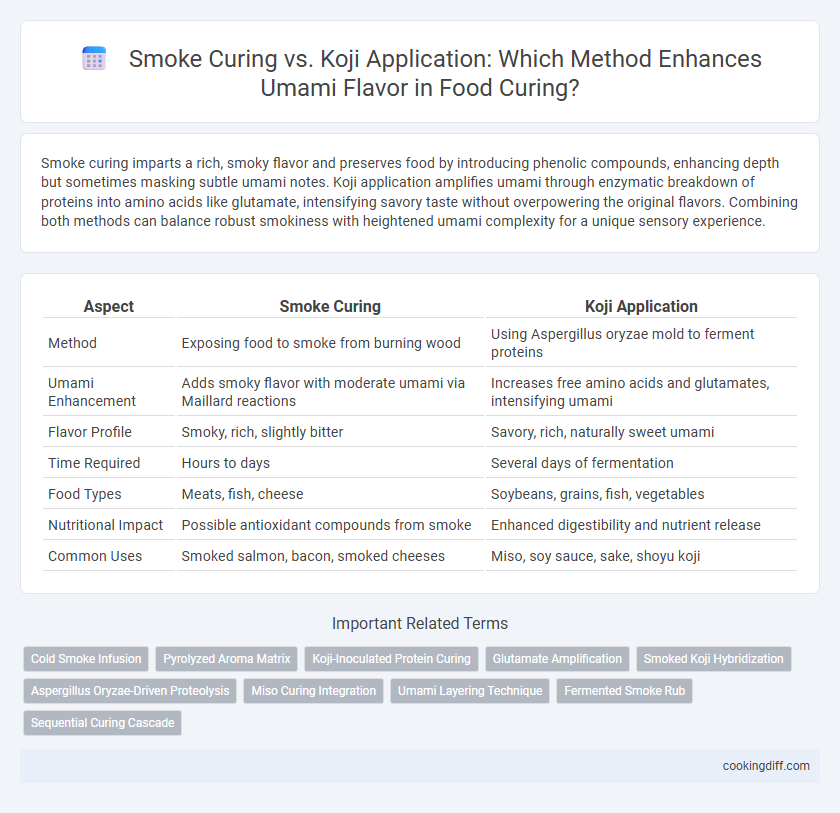

| Aspect | Smoke Curing | Koji Application |

|---|---|---|

| Method | Exposing food to smoke from burning wood | Using Aspergillus oryzae mold to ferment proteins |

| Umami Enhancement | Adds smoky flavor with moderate umami via Maillard reactions | Increases free amino acids and glutamates, intensifying umami |

| Flavor Profile | Smoky, rich, slightly bitter | Savory, rich, naturally sweet umami |

| Time Required | Hours to days | Several days of fermentation |

| Food Types | Meats, fish, cheese | Soybeans, grains, fish, vegetables |

| Nutritional Impact | Possible antioxidant compounds from smoke | Enhanced digestibility and nutrient release |

| Common Uses | Smoked salmon, bacon, smoked cheeses | Miso, soy sauce, sake, shoyu koji |

Introduction to Umami Enhancement in Cooking

Umami is a fundamental taste that enhances the savory quality of foods and is often amplified through various curing techniques. Smoke curing and koji application represent two distinct methods for intensifying umami flavors in culinary practices.

- Smoke Curing - Introduces smoky aromas and complex phenolic compounds that deepen the savory profile of meats and fish.

- Koji Application - Utilizes mold enzymes to break down proteins into amino acids like glutamate, significantly boosting umami taste.

- Comparative Impact - Koji curing tends to produce higher levels of free glutamates, while smoke curing adds aromatic complexity, making both effective for umami enhancement in different ways.

Fundamentals of Smoke Curing

Smoke curing relies on the chemical interaction between smoke compounds, such as phenols and carbonyls, and the food's surface to develop complex flavors and enhance preservation. This process introduces smoky aromas and a subtle bitterness that contribute to a rich umami profile, distinct from enzymatic methods.

Koji application utilizes Aspergillus oryzae to enzymatically break down proteins into amino acids, intensifying umami through glutamate production. Smoke curing, by contrast, primarily alters flavor via pyrolysis-derived compounds without significantly increasing free amino acid content.

Understanding Koji Application

Koji application involves using Aspergillus oryzae mold to ferment proteins and starches, significantly boosting umami through the generation of amino acids like glutamate. This method enhances depth and complexity of flavor beyond traditional smoke curing, which primarily adds smoky notes.

During koji fermentation, enzymes break down proteins into savory peptides and free amino acids, intensifying the umami profile in foods such as meats and soy products. Unlike smoke curing that relies on phenolic compounds for flavor, koji develops rich, naturally savory tastes through biochemical transformation. This process can be controlled to optimize flavor intensity and texture, making it a preferred technique for enhancing umami in artisanal and gourmet food production.

Chemical Processes Behind Smoke Curing

Smoke curing enhances umami primarily through the Maillard reaction and phenolic compound absorption, creating complex flavor profiles. Koji application increases umami by enzymatic breakdown of proteins into free amino acids, particularly glutamate.

- Maillard Reaction - Smoke curing induces non-enzymatic browning that forms savory flavor compounds enhancing umami taste.

- Phenolic Compounds - Smoke particles deposit phenols which contribute smoky aroma and enhance perceived umami intensity.

- Enzymatic Hydrolysis - Koji mold enzymes degrade proteins into glutamic acid, boosting naturally occurring umami flavors.

How Koji Fermentation Enhances Umami

Koji fermentation enhances umami by breaking down proteins into free amino acids such as glutamate, which intensifies savory flavors. This enzymatic process results in a deeper, more complex taste compared to traditional smoke curing methods.

- Proteolytic enzymes - Koji produces enzymes that hydrolyze proteins into amino acids, amplifying umami compounds.

- Glutamate concentration - Fermentation significantly increases free glutamate levels, the key molecule responsible for umami taste.

- Flavor complexity - Koji fermentation generates diverse peptides that contribute to richer, layered flavor profiles.

Smoke curing imparts aroma and preservation qualities but lacks the enzymatic enhancement of umami found in koji fermentation.

Flavor Profiles: Smoke Curing vs Koji

| Flavor Profile Aspect | Smoke Curing | Koji Application |

|---|---|---|

| Umami Enhancement | Imparts rich, smoky, and slightly bitter notes that deepen savory complexity. | Produces intensified umami through enzymatic breakdown of proteins into glutamates and amino acids. |

| Aroma | Offers intense woodsy and charred aromas from combustion of different woods. | Delivers subtle, sweet, and fermented aromas due to mold metabolism. |

| Flavor Complexity | Combines smoky, meaty, and cured notes creating a bold, layered taste experience. | Creates delicate, nuanced flavors with savory, sweet, and slightly tangy undertones. |

Nutritional Impacts of Each Method

Smoke curing introduces phenolic compounds and antioxidants that can contribute to slight nutritional benefits, whereas koji application significantly enhances the glutamate content, boosting umami and promoting amino acid profiles beneficial for digestion. While smoke curing primarily preserves food through antimicrobial properties, koji fermentation actively transforms proteins into bioavailable nutrients, increasing overall nutritional value.

Koji's enzymatic action enriches vitamins and peptides, supporting gut health, contrasting with smoke curing's tendency to introduce polycyclic aromatic hydrocarbons, which may pose health risks when consumed in excess. Nutritionally, koji application offers a safer and more potent method to elevate umami and improve food quality compared to traditional smoke curing.

Applications in Modern and Traditional Cuisine

Smoke curing imparts a rich, smoky flavor and preserves food through phenolic compounds, widely used in traditional cuisines for meats and fish, enhancing umami by intensifying amino acid profiles. Koji application leverages enzymatic fermentation by Aspergillus oryzae to break down proteins into free amino acids and peptides, boosting umami depth in modern and classic Japanese dishes like miso and soy sauce. Combining smoke curing with koji fermentation offers innovative culinary techniques that amplify savory complexity and texture in diverse gastronomic applications.

Safety and Practicality Considerations

Smoke curing involves exposing food to smoke, which introduces phenolic compounds that enhance umami while also acting as natural preservatives, but it requires careful control to avoid harmful polycyclic aromatic hydrocarbons (PAHs). Koji application uses Aspergillus oryzae fermentation to amplify umami through enzymatic breakdown of proteins into amino acids, offering a safer and more controlled process without the risk of toxic compounds. Practically, koji requires precise humidity and temperature management, whereas smoke curing demands specialized smoking equipment and ventilation systems to ensure safety and consistency.

Related Important Terms

Cold Smoke Infusion

Cold smoke infusion enhances umami by gently infusing food with smoky phenols without heat, preserving delicate flavors that synergize with koji's enzymatic breakdown of proteins into amino acids like glutamate. Combining smoke curing with koji application amplifies savory depth through complex flavor layering, optimizing umami intensity in products such as smoked fish and aged meats.

Pyrolyzed Aroma Matrix

Smoke curing imparts a complex pyrolyzed aroma matrix through thermal decomposition of wood compounds, enhancing umami by introducing smoky, caramelized, and roasted flavor notes that stimulate glutamate receptors. Koji application enzymatically produces glutamate and other amino acids, intensifying umami with cleaner, fermented flavors but lacks the distinct smoky pyrolysis profile found in traditional smoke curing.

Koji-Inoculated Protein Curing

Koji-inoculated protein curing significantly enhances umami through enzymatic breakdown of proteins into amino acids, especially glutamate, compared to traditional smoke curing which primarily imparts phenolic flavors without increasing savory depth. The enzymatic activity of Aspergillus oryzae in koji converts complex proteins into rich, flavorful peptides, offering a natural, health-conscious alternative to smoke curing for umami intensification.

Glutamate Amplification

Smoke curing intensifies umami primarily through the Maillard reaction and compounds like guaiacol, which complement glutamate but do not directly increase its levels. Koji application, rich in enzymes such as proteases and glutaminases, actively amplifies free glutamate by breaking down proteins, resulting in a more pronounced and natural umami flavor enhancement.

Smoked Koji Hybridization

Smoke curing enhances umami by introducing phenolic compounds, while koji fermentation produces glutamates and nucleotides that amplify savory flavors; combining these methods in smoked koji hybridization synergistically maximizes umami complexity. This hybrid approach leverages enzymatic breakdown from koji with aromatic depth from smoke, creating a uniquely intensified umami profile beneficial for meat and seafood preservation.

Aspergillus Oryzae-Driven Proteolysis

Aspergillus oryzae-driven proteolysis in koji application effectively enhances umami by breaking down proteins into amino acids such as glutamate, which intensifies savory flavors in cured products. Unlike traditional smoke curing that imparts smoky notes, koji fermentation specifically amplifies natural umami through enzymatic hydrolysis, resulting in a complex taste profile rich in peptides and free amino acids.

Miso Curing Integration

Smoke curing imparts complex smoky flavors and depth to foods by introducing phenolic compounds, whereas koji application enhances umami through enzymatic breakdown of proteins into amino acids like glutamate, crucial in miso curing. Integrating smoke curing with koji fermentation in miso production can synergistically develop rich, savory profiles by combining smoky aroma with intensified umami compounds.

Umami Layering Technique

Smoke curing imparts complex smoky phenols that synergize with natural glutamates to deepen umami flavor, creating rich and savory profiles through chemical Maillard reactions. Koji application introduces enzymatic fermentation, releasing free amino acids and nucleotides that enhance umami via layered biological intensification, allowing for nuanced depth and mouthfeel in foods.

Fermented Smoke Rub

Fermented smoke rub combines smoke curing's deep phenolic flavors with koji's enzymatic action to amplify glutamate concentration, significantly enhancing umami depth in meats. This fusion process accelerates protein breakdown and stimulates amino acid development, creating a complex, savory profile unmatched by traditional smoke curing alone.

Smoke curing vs koji application for enhancing umami. Infographic

cookingdiff.com

cookingdiff.com