Seasoned cast iron offers a natural non-stick surface that improves with use, making it ideal for curing pans due to its ability to retain and evenly distribute heat. Nitro-carburized steel provides enhanced surface hardness and corrosion resistance, resulting in a durable curing pan that requires less maintenance. Choosing between these materials depends on the desired balance between traditional seasoning benefits and the low-maintenance durability of nitro-carburized steel.

Table of Comparison

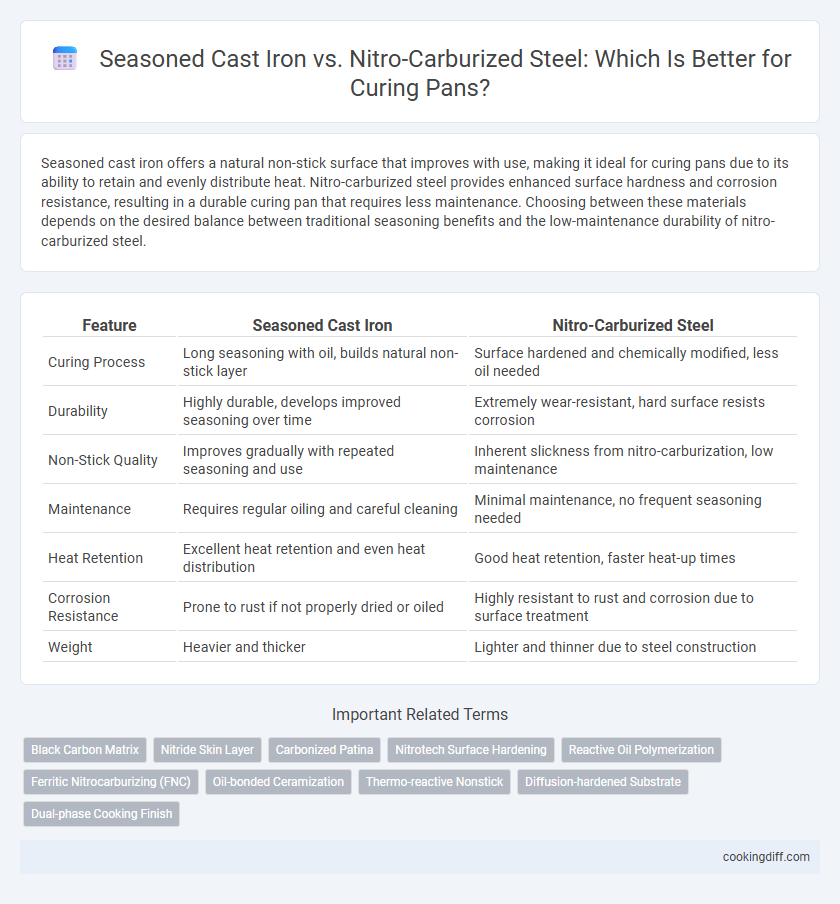

| Feature | Seasoned Cast Iron | Nitro-Carburized Steel |

|---|---|---|

| Curing Process | Long seasoning with oil, builds natural non-stick layer | Surface hardened and chemically modified, less oil needed |

| Durability | Highly durable, develops improved seasoning over time | Extremely wear-resistant, hard surface resists corrosion |

| Non-Stick Quality | Improves gradually with repeated seasoning and use | Inherent slickness from nitro-carburization, low maintenance |

| Maintenance | Requires regular oiling and careful cleaning | Minimal maintenance, no frequent seasoning needed |

| Heat Retention | Excellent heat retention and even heat distribution | Good heat retention, faster heat-up times |

| Corrosion Resistance | Prone to rust if not properly dried or oiled | Highly resistant to rust and corrosion due to surface treatment |

| Weight | Heavier and thicker | Lighter and thinner due to steel construction |

Introduction to Curing Pans: Why Material Matters

| Seasoned Cast Iron: Known for its excellent heat retention and natural non-stick surface, seasoned cast iron develops a durable seasoning layer through repeated curing, enhancing pan longevity and cooking performance. |

| Nitro-Carburized Steel: Features a hardened surface created via gas treatment, offering enhanced corrosion resistance and durability, but requires different curing techniques to build an effective non-stick layer compared to seasoned cast iron. |

| Material composition directly influences curing methods, affecting pan maintenance, seasoning quality, and overall cooking results, making the choice between cast iron and nitro-carburized steel crucial for optimal pan performance. |

What Is Seasoned Cast Iron?

What is seasoned cast iron and how does it affect curing pans? Seasoned cast iron refers to cast iron cookware that has been coated with a layer of polymerized oil, creating a non-stick surface that improves with use. This seasoning protects the pan from rust, enhances heat retention, and contributes to a natural, durable cooking surface ideal for curing processes.

Understanding Nitro-Carburized Steel

Nitro-carburized steel undergoes a surface-hardening process combining nitrogen and carbon diffusion, significantly enhancing corrosion resistance and wear durability. This treatment creates a dense, wear-resistant layer that reduces the need for frequent seasoning compared to traditional cast iron. The improved chemical stability of nitro-carburized steel means it maintains a non-stick surface and requires less maintenance during curing cycles.

Heat Retention and Distribution: A Comparative Analysis

Seasoned cast iron offers superior heat retention due to its dense composition, maintaining consistent temperatures essential for curing pans. Nitro-carburized steel provides faster heat distribution but lacks the prolonged heat retention found in cast iron.

- Heat Retention in Cast Iron - Retains heat longer, ensuring steady curing temperatures.

- Heat Distribution in Nitro-Carburized Steel - Distributes heat quickly and evenly across the pan surface.

- Material Density Impact - Cast iron's density contributes to its ability to hold heat versus the thinner nitro-carburized steel.

Choosing between the two depends on whether sustained heat or rapid heat spread is more critical for your curing process.

Durability and Longevity: Cast Iron vs Nitro-Carburized Steel

Seasoned cast iron pans develop a natural non-stick surface that improves with use, offering exceptional durability due to their resistance to warping and high heat retention. Nitro-carburized steel pans feature a hardened surface layer created through a thermochemical treatment, enhancing corrosion resistance and wear properties significantly. While cast iron excels in long-term longevity with proper care, nitro-carburized steel provides superior scratch resistance and reduced maintenance for durability in aggressive cooking environments.

Nonstick Properties: Seasoning Versus Chemical Treatment

Seasoned cast iron develops a natural nonstick surface through polymerized oils baked into the pan, enhancing with use and proper maintenance. Nitro-carburized steel achieves nonstick properties via a chemical diffusion process that hardens the surface, providing immediate resistance to sticking without the need for seasoning.

- Seasoned Cast Iron Creates a Polymerized Oil Layer - The seasoning process builds a durable, nonstick coating that improves with repeated heating and oil application.

- Nitro-Carburized Steel Enhances Surface Hardness Chemically - Chemical treatment diffuses nitrogen and carbon into the steel, producing a hardened, wear-resistant surface with inherent nonstick qualities.

- Nonstick Performance Evolves Differently - Cast iron's nonstick effect strengthens over time through seasoning, while nitro-carburized steel offers consistent performance from the outset.

Maintenance and Care Requirements

Seasoned cast iron requires regular oiling and careful drying to prevent rust and maintain its non-stick surface. Nitro-carburized steel offers enhanced corrosion resistance, demanding less frequent seasoning and simpler maintenance.

- Seasoned Cast Iron - Needs thorough drying after washing to avoid rust and requires periodic re-oiling to preserve the seasoning layer.

- Nitro-Carburized Steel - Features a hardened surface that resists rust, reducing the frequency of seasoning compared to cast iron.

- Maintenance Effort - Cast iron demands consistent care to sustain its performance, while nitro-carburized steel is more forgiving and easier to maintain over time.

Flavor Development During Curing: Material Impact

Seasoned cast iron pans develop a rich, complex flavor profile as their porous surface absorbs oils and seasoning layers over time, enhancing the curing process. Nitro-carburized steel pans offer superior corrosion resistance but lack the porous texture that facilitates deep seasoning and flavor infusion.

The curing of cast iron improves flavor depth by creating a natural non-stick surface embedded with polymerized oils, which intensifies with continued use. Nitro-carburized steel provides a harder, more durable surface that resists wear and oxidation, yet this limits the pan's ability to build flavor complexity through seasoning. Ultimately, the choice between these materials affects how flavors develop and mature during cooking, with cast iron favored for its traditional seasoning properties and nitro-carburized steel prized for durability and maintenance ease.

Price and Accessibility Differences

Seasoned cast iron pans tend to be more affordable, with prices often ranging between $20 to $100 depending on the brand and size, making them accessible for most home cooks. Nitro-carburized steel pans, due to specialized surface treatments, generally command higher prices, frequently exceeding $150.

Cast iron pans benefit from widespread availability in kitchen stores and online marketplaces, ensuring easy access for consumers. In contrast, nitro-carburized steel pans are less common and primarily found through specialty retailers or direct manufacturer sales, limiting their immediate accessibility.

Related Important Terms

Black Carbon Matrix

Seasoned cast iron develops a durable black carbon matrix through polymerized oils, creating a natural non-stick surface that enhances flavor and heat retention. Nitro-carburized steel forms a hard, corrosion-resistant black oxide layer, offering less seasoning buildup but improved wear resistance and easier maintenance over time.

Nitride Skin Layer

Nitro-carburized steel pans develop a hard nitride skin layer that enhances corrosion resistance and creates a naturally non-stick surface ideal for curing without extensive seasoning. This nitride layer provides superior durability compared to the porous surface of seasoned cast iron, reducing maintenance and improving pan longevity.

Carbonized Patina

Seasoned cast iron develops a carbonized patina through repeated oil polymerization, creating a natural non-stick surface that enhances durability and flavor release. Nitro-carburized steel forms a harder, chemically bonded oxide layer that offers corrosion resistance but lacks the traditional carbonized patina's depth and seasoning benefits essential for optimal pan curing.

Nitrotech Surface Hardening

Nitrotech Surface Hardening significantly enhances nitro-carburized steel pans by creating a durable, corrosion-resistant layer that improves seasoning retention and cooking performance compared to traditional seasoned cast iron. This advanced treatment reduces maintenance needs while providing a harder, more non-stick surface ideal for long-term use in curing cookware.

Reactive Oil Polymerization

Seasoned cast iron pans develop a natural non-stick surface through reactive oil polymerization, creating a durable, hydrophobic layer that enhances cooking performance. Nitro-carburized steel pans also benefit from surface hardening but typically require additional seasoning steps to achieve a similar polymerized oil coating, influencing their long-term non-stick properties and maintenance.

Ferritic Nitrocarburizing (FNC)

Ferritic Nitrocarburizing (FNC) enhances steel pans with a hardened, corrosion-resistant surface ideal for curing, offering superior wear resistance compared to seasoned cast iron by reducing oxidation and sticking. FNC-treated nitro-carburized steel pans maintain a naturally non-stick surface without the need for frequent seasoning, optimizing durability and cooking performance.

Oil-bonded Ceramization

Oil-bonded ceramization enhances durability and non-stick properties by forming a robust ceramic layer on the pan surface, with nitro-carburized steel offering superior hardness and corrosion resistance compared to seasoned cast iron. This advanced surface treatment on nitro-carburized steel ensures more effective curing, resulting in longer-lasting, easy-to-clean pans ideal for high-performance cooking.

Thermo-reactive Nonstick

Seasoned cast iron develops a thermo-reactive nonstick surface through polymerized oil that bonds to the pan's surface, enhancing durability and flavor over time. Nitro-carburized steel undergoes a controlled thermochemical treatment that forms a hardened, corrosion-resistant layer with inherent nonstick properties, requiring minimal maintenance compared to traditional seasoning methods.

Diffusion-hardened Substrate

Seasoned cast iron develops a natural non-stick surface through polymerized oils, enhancing durability and heat retention, while nitro-carburized steel features a diffusion-hardened substrate that significantly improves surface hardness and corrosion resistance. The diffusion-hardening process in nitro-carburized steel enables deeper nitrogen and carbon penetration, resulting in a robust and wear-resistant cooking surface optimized for curing pans.

Seasoned cast iron vs nitro-carburized steel for curing pans. Infographic

cookingdiff.com

cookingdiff.com