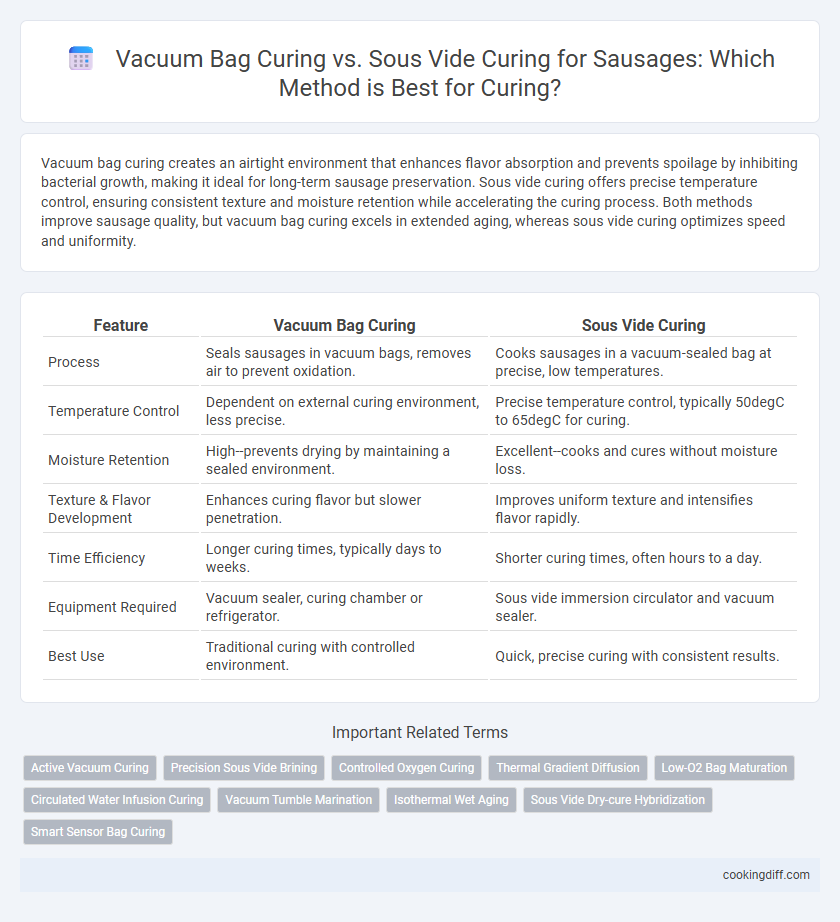

Vacuum bag curing creates an airtight environment that enhances flavor absorption and prevents spoilage by inhibiting bacterial growth, making it ideal for long-term sausage preservation. Sous vide curing offers precise temperature control, ensuring consistent texture and moisture retention while accelerating the curing process. Both methods improve sausage quality, but vacuum bag curing excels in extended aging, whereas sous vide curing optimizes speed and uniformity.

Table of Comparison

| Feature | Vacuum Bag Curing | Sous Vide Curing |

|---|---|---|

| Process | Seals sausages in vacuum bags, removes air to prevent oxidation. | Cooks sausages in a vacuum-sealed bag at precise, low temperatures. |

| Temperature Control | Dependent on external curing environment, less precise. | Precise temperature control, typically 50degC to 65degC for curing. |

| Moisture Retention | High--prevents drying by maintaining a sealed environment. | Excellent--cooks and cures without moisture loss. |

| Texture & Flavor Development | Enhances curing flavor but slower penetration. | Improves uniform texture and intensifies flavor rapidly. |

| Time Efficiency | Longer curing times, typically days to weeks. | Shorter curing times, often hours to a day. |

| Equipment Required | Vacuum sealer, curing chamber or refrigerator. | Sous vide immersion circulator and vacuum sealer. |

| Best Use | Traditional curing with controlled environment. | Quick, precise curing with consistent results. |

Introduction to Sausage Curing Methods

Sausage curing methods play a crucial role in flavor development and preservation. Vacuum bag curing and sous vide curing are two popular techniques that differ in process and outcome.

- Vacuum Bag Curing - Involves sealing sausages in airtight bags to enhance flavor penetration and reduce oxidation.

- Sous Vide Curing - Uses precise temperature control in water baths to uniformly cure sausages, improving texture and safety.

- Comparative Benefits - Vacuum bag curing is simpler and faster, while sous vide curing offers consistency and enhanced tenderization.

Understanding these methods helps optimize sausage quality based on desired flavor and texture profiles.

What is Vacuum Bag Curing?

What is vacuum bag curing in sausage preparation? Vacuum bag curing involves sealing sausages in airtight plastic bags to remove air and enhance flavor absorption. This method prevents oxidation and promotes even curing by maintaining a controlled environment around the meat.

What is Sous Vide Curing?

Sous vide curing is a precise method that involves vacuum-sealing sausages and cooking them at a controlled low temperature in a water bath. This technique ensures even curing and preserves the texture and moisture of the sausages.

The controlled temperature environment allows for the development of complex flavors without the risk of overcooking. Sous vide curing also minimizes oxidation and bacterial growth, making it ideal for artisanal sausage production.

Key Differences Between Vacuum Bag and Sous Vide Curing

Vacuum bag curing removes air to create a tightly sealed environment that enhances flavor absorption and extends shelf life, while sous vide curing uses precise temperature control in a water bath to evenly cure sausages and maintain texture. Vacuum bag curing is typically faster but less consistent in temperature regulation compared to the sous vide method, which offers exact curing times and temperatures. Sous vide curing also reduces oxidation and microbial growth more effectively, resulting in safer and higher quality cured sausages.

Equipment Needed for Each Method

Vacuum bag curing requires specialized vacuum sealers to remove air and seal the sausages securely, while sous vide curing depends on precise temperature-controlled water baths for even cooking and curing. Each method demands specific equipment tailored to maintain optimal conditions for flavor and safety in sausage curing.

- Vacuum Sealer - Essential for removing air and sealing sausages in vacuum bags to prevent spoilage and enhance curing efficiency.

- Vacuum Bags - Durable, food-safe bags required for holding the sausages during vacuum sealing and curing processes.

- Sous Vide Cooker - Provides precise temperature control by circulating water evenly, critical for consistent sous vide curing results.

Time and Temperature Considerations

Vacuum bag curing typically requires longer curing times at slightly higher temperatures to ensure thorough preservation and flavor development. Sous vide curing offers precise temperature control, allowing for shorter curing durations while maintaining consistent texture and safety standards.

- Vacuum Bag Curing Time - Often ranges from several days to weeks depending on sausage size and desired flavor intensity.

- Sous Vide Temperature Control - Maintains a stable temperature, usually between 50degC and 65degC, optimizing enzymatic activity and bacterial safety.

- Time Efficiency - Sous vide curing accelerates the curing process by uniformly heating sausages, reducing the risk of under-curing compared to vacuum bag methods.

Flavor and Texture Outcomes

| Vacuum Bag Curing | Enhances flavor penetration through direct contact with curing agents, producing a firmer texture due to moisture retention control. |

| Sous Vide Curing | Delivers even flavor distribution by precise temperature control, resulting in a tender, evenly cooked texture with enhanced juiciness. |

Food Safety and Preservation

Vacuum bag curing removes air to inhibit bacterial growth, enhancing food safety and extending sausage shelf life. Sous vide curing uses precise temperature control in a water bath, ensuring consistent preservation and reducing pathogen risk. Both methods offer effective curing techniques, but vacuum bag curing excels in oxygen barrier protection while sous vide maintains optimal moisture and texture.

Pros and Cons of Each Curing Technique

Vacuum bag curing offers precise control over moisture and flavor retention by tightly sealing sausages, which helps prevent contamination and evaporation during the curing process. This method is efficient for small batches but can sometimes result in uneven curing if not monitored properly.

Sous vide curing ensures a consistent temperature throughout the curing period, promoting uniform texture and deeply infused flavors, ideal for delicate sausage varieties. However, it requires specialized equipment and longer curing times, which may not be cost-effective for all producers. Moreover, precise temperature control is critical to prevent bacterial growth and ensure food safety.

Related Important Terms

Active Vacuum Curing

Active vacuum curing enhances flavor penetration and moisture retention in sausages by applying consistent vacuum pressure that accelerates the curing process and ensures uniform ingredient distribution. This method outperforms sous vide curing by combining vacuum technology with controlled temperature, resulting in superior texture and reduced curing time.

Precision Sous Vide Brining

Vacuum bag curing offers enhanced flavor infusion by tightly sealing sausages, but precision sous vide brining delivers superior temperature control and uniform curing through consistent water bath immersion. This method minimizes bacterial risk and ensures even salt and seasoning penetration, optimizing texture and taste in sausage curing.

Controlled Oxygen Curing

Vacuum bag curing minimizes oxygen exposure by creating an airtight seal around sausages, essential for controlled oxygen curing that prevents spoilage and bacterial growth. Sous vide curing, while precise in temperature control, often allows more oxygen interaction, making vacuum bag curing a superior method for maintaining optimal texture and flavor in sausage production.

Thermal Gradient Diffusion

Vacuum bag curing creates an uneven thermal gradient diffusion in sausages, resulting in inconsistent flavor and moisture distribution, whereas sous vide curing maintains a precise and uniform thermal gradient that promotes even diffusion of curing agents throughout the meat. This consistent heat transfer in sous vide curing enhances texture quality and ensures optimal preservation by minimizing temperature fluctuations.

Low-O2 Bag Maturation

Vacuum bag curing extends sausage shelf life by creating a low-oxygen environment that minimizes oxidative spoilage and microbial growth, enhancing flavor development during maturation. Sous vide curing, while also controlling oxygen exposure, primarily relies on precise temperature regulation, but vacuum bag curing offers superior low-O2 bag maturation for consistent texture and extended preservation.

Circulated Water Infusion Curing

Circulated water infusion curing, as used in sous vide curing, ensures even temperature distribution and precise control, resulting in consistent texture and flavor development in sausages. Unlike vacuum bag curing, which relies on static conditions, this method enhances moisture retention and reduces curing time through continuous water circulation.

Vacuum Tumble Marination

Vacuum tumble marination enhances sausage curing by speeding up flavor absorption and ensuring even distribution of curing agents within the meat fibers, outperforming traditional vacuum bag curing that relies on static immersion. Sous vide curing maintains precise temperature control but lacks the mechanical action that vacuum tumbling provides, making vacuum tumble marination more efficient for consistent texture and accelerated marinade penetration in sausage production.

Isothermal Wet Aging

Vacuum bag curing maintains a consistent isothermal wet aging environment by tightly sealing sausages, preserving moisture and enhancing flavor development through controlled enzymatic activity. Sous vide curing offers precise temperature regulation and uniform heat transfer, optimizing protein breakdown and tenderness during isothermal wet aging without drying or oxidation.

Sous Vide Dry-cure Hybridization

Sous Vide Dry-cure Hybridization enhances sausage curing by combining precise temperature control with dry-curing benefits, resulting in improved flavor development, texture, and food safety. This method offers superior moisture retention and consistent curing outcomes compared to traditional vacuum bag curing, optimizing both the taste profile and shelf life of dry-cured sausages.

Vacuum Bag Curing vs Sous Vide Curing for sausages. Infographic

cookingdiff.com

cookingdiff.com