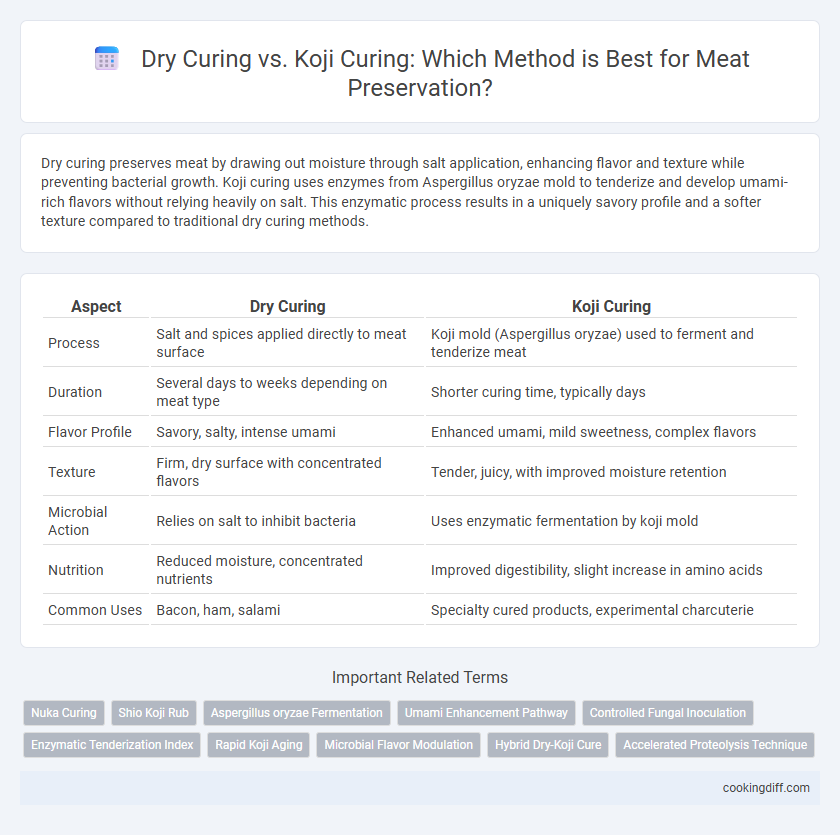

Dry curing preserves meat by drawing out moisture through salt application, enhancing flavor and texture while preventing bacterial growth. Koji curing uses enzymes from Aspergillus oryzae mold to tenderize and develop umami-rich flavors without relying heavily on salt. This enzymatic process results in a uniquely savory profile and a softer texture compared to traditional dry curing methods.

Table of Comparison

| Aspect | Dry Curing | Koji Curing |

|---|---|---|

| Process | Salt and spices applied directly to meat surface | Koji mold (Aspergillus oryzae) used to ferment and tenderize meat |

| Duration | Several days to weeks depending on meat type | Shorter curing time, typically days |

| Flavor Profile | Savory, salty, intense umami | Enhanced umami, mild sweetness, complex flavors |

| Texture | Firm, dry surface with concentrated flavors | Tender, juicy, with improved moisture retention |

| Microbial Action | Relies on salt to inhibit bacteria | Uses enzymatic fermentation by koji mold |

| Nutrition | Reduced moisture, concentrated nutrients | Improved digestibility, slight increase in amino acids |

| Common Uses | Bacon, ham, salami | Specialty cured products, experimental charcuterie |

Introduction to Meat Curing Methods

Dry curing involves applying a mixture of salt, sugar, and spices directly to the meat's surface, which draws out moisture and preserves the meat through dehydration and flavor concentration. Koji curing utilizes the mold Aspergillus oryzae to ferment enzymes that tenderize and enhance meat flavor while promoting umami development. Both methods serve to preserve meat but differ significantly in their biochemical processes and flavor profiles.

What is Dry Curing?

What is dry curing in meat preservation? Dry curing is a traditional method where salt and spices are rubbed directly onto the meat's surface to draw out moisture and enhance flavor. This process creates an environment that inhibits bacterial growth, resulting in a distinct texture and rich taste.

What is Koji Curing?

| Koji Curing is a traditional Japanese method that uses the mold Aspergillus oryzae to ferment and tenderize meat, enhancing umami flavor through enzymatic breakdown of proteins and fats. Unlike dry curing, which relies on salt to preserve and dehydrate meat, koji curing accelerates flavor development and improves texture by enzymatic activity without excessive salt. This process results in deeply savory, tender meat with a unique, naturally produced sweetness and complex flavor profile. |

Key Differences Between Dry Curing and Koji Curing

Dry curing involves rubbing salt and spices directly onto the meat's surface to draw out moisture and preserve it through dehydration. This traditional method enhances flavor through slow aging and relies primarily on salt's antimicrobial properties.

Koji curing uses the mold Aspergillus oryzae to enzymatically break down proteins and fats in the meat, creating unique umami flavors and tender textures. This technique accelerates curing by enhancing enzymatic activity rather than solely relying on salt penetration.

Flavor Profiles: Dry Cured vs Koji Cured Meat

Dry curing intensifies meat with a robust, salty flavor through salt and time, while koji curing imparts a subtle umami depth from its enzymatic fermentation process. Koji-cured meat also tends to have a tender texture and mild sweetness that contrasts with the firm, concentrated taste of dry-cured meat.

- Dry Cured Flavor - Characterized by bold saltiness and rich, concentrated meatiness developed over extended curing periods.

- Koji Cured Flavor - Offers delicate umami and subtle sweetness derived from koji mold enzymes breaking down proteins and fats.

- Texture Contrast - Dry cured meat is firmer and denser, whereas koji curing yields a tender, melt-in-mouth consistency.

Health and Safety Considerations

Dry curing involves applying salt and spices directly to meat, reducing microbial growth through dehydration and creating an inhospitable environment for pathogens. This traditional method requires strict temperature and humidity controls to prevent harmful bacterial contamination and ensure food safety.

Koji curing uses Aspergillus oryzae enzymes to break down proteins and fats, promoting flavor development while inhibiting spoilage organisms. This fermentation process enhances digestibility and may reduce harmful compounds, offering potential health benefits. Proper hygiene and monitoring are critical to avoid mycotoxin production and ensure safe consumption.

Texture Changes in Dry and Koji Curing

Dry curing meat results in a firmer texture due to moisture loss and protein denaturation, which intensifies flavor concentration. In contrast, koji curing uses enzymatic activity from Aspergillus oryzae to break down proteins and fats, producing a tender, more complex texture.

Texture changes in dry curing are primarily driven by salt penetration and dehydration, leading to a chewy and dense bite. Koji curing enhances meat softness and juiciness by enzymatically tenderizing muscle fibers and retaining moisture content.

Equipment and Ingredients Needed

Dry curing requires minimal equipment but a controlled environment with curing chambers or coolers to regulate temperature and humidity, using salt, sugar, and nitrites as key ingredients. Koji curing demands specialized koji spores and a humidity-controlled fermentation space, relying on the enzymatic action of Aspergillus oryzae to tenderize and flavor the meat.

- Dry curing equipment - Basic curing chambers or refrigerators maintain necessary low temperatures and humidity levels.

- Koji curing ingredients - Aspergillus oryzae spores are essential to ferment and enhance meat texture and flavor.

- Dry curing ingredients - Salt, sugar, and curing salts like sodium nitrite are used to preserve and season meat.

Each method's unique requirements impact the complexity and flavor profile of the cured meat.

Pros and Cons of Each Curing Method

Dry curing involves applying salt and seasonings directly to the meat, enhancing flavor complexity and extending shelf life but requiring longer processing time and precise humidity control to prevent spoilage. Koji curing utilizes the mold Aspergillus oryzae to break down proteins and fats, accelerating tenderization and imparting umami-rich flavor, yet it demands specialized knowledge and may not offer as long preservation as dry curing. Each method offers distinct advantages: dry curing excels in traditional preservation and robust taste, while koji curing provides faster maturation and unique savory profiles.

Related Important Terms

Nuka Curing

Nuka curing, a traditional Japanese dry curing method, utilizes rice bran (nuka) rich in enzymes and probiotics to enhance meat flavor and tenderness while naturally preserving it. Unlike standard dry curing, nuka curing imparts umami depth and a subtle fermentation taste, accelerating flavor development through microbial activity unique to koji-based fermentation.

Shio Koji Rub

Shio Koji rub enhances meat curing by utilizing naturally occurring enzymes in koji to tenderize and develop deep umami flavors, differing from traditional dry curing which relies primarily on salt and extended drying times. This fermentation-based approach accelerates flavor infusion and moisture retention, creating a uniquely savory profile unattainable with classic dry curing methods.

Aspergillus oryzae Fermentation

Koji curing utilizes Aspergillus oryzae fermentation to enhance meat flavor and tenderness by breaking down proteins and fats more efficiently than traditional dry curing, which relies primarily on salt and time for preservation. This biological process in koji curing accelerates enzymatic activity, resulting in a distinct umami profile and improved texture compared to conventional dry-cured meats.

Umami Enhancement Pathway

Dry curing intensifies meat flavor through slow salt-induced moisture loss, concentrating natural glutamates that heighten umami perception; koji curing employs Aspergillus oryzae enzymes to break down proteins into amino acids such as glutamate and peptides, significantly amplifying the umami taste via enzymatic fermentation. The umami enhancement pathway in koji curing involves accelerated proteolysis and amino acid release, which contrasts with the passive concentration effect in dry curing, resulting in a richer and more complex savory profile.

Controlled Fungal Inoculation

Dry curing relies on salt and environmental conditions to dehydrate and preserve meat, enhancing flavor through slow enzymatic processes, while koji curing employs controlled fungal inoculation using Aspergillus oryzae to accelerate proteolysis and develop umami-rich compounds. This precise fungal fermentation in koji curing results in unique tenderization and complex flavor profiles distinct from traditional dry curing methods.

Enzymatic Tenderization Index

Dry curing relies on salt and prolonged aging to enhance flavor and preservation but offers limited enzymatic tenderization, whereas koji curing utilizes Aspergillus oryzae enzymes to significantly elevate the Enzymatic Tenderization Index, resulting in superior meat tenderness and umami development. Studies show that koji curing can increase proteolytic activity by up to 40%, accelerating muscle protein breakdown and improving texture compared to traditional dry curing methods.

Rapid Koji Aging

Rapid Koji aging accelerates the curing process by leveraging the enzymatic activity of Aspergillus oryzae, which breaks down proteins and fats more efficiently than traditional dry curing methods. This results in enhanced flavor development and tenderness in meat within a significantly shorter timeframe compared to conventional dry curing.

Microbial Flavor Modulation

Dry curing relies on salt and natural microbial fermentation to develop complex flavors through lactic acid bacteria and mold activity, enhancing umami and savory notes in meat. Koji curing employs Aspergillus oryzae fungi to enzymatically break down proteins and fats, producing distinct amino acids and peptides that modulate flavor with subtle sweetness and depth.

Hybrid Dry-Koji Cure

Hybrid dry-Koji curing combines the traditional salt-based preservation of dry curing with the enzymatic fermentation of koji, resulting in enhanced flavor complexity and improved texture in meat. This method leverages Aspergillus oryzae enzymes to break down proteins while maintaining the moisture control of dry curing, offering a balanced approach to meat preservation and taste development.

Dry Curing vs Koji Curing for meat. Infographic

cookingdiff.com

cookingdiff.com