Repeated oiling creates a durable, non-stick surface by layering thin films of polymerized oil over time, enhancing the pan's resistance to rust and improving seasoning depth. Single high-temp seasoning forms a hard, often brittle coating that can flake under heavy use and may require frequent re-seasoning. Consistent repeated oiling yields a more resilient and flexible seasoning that adapts better to regular cooking demands.

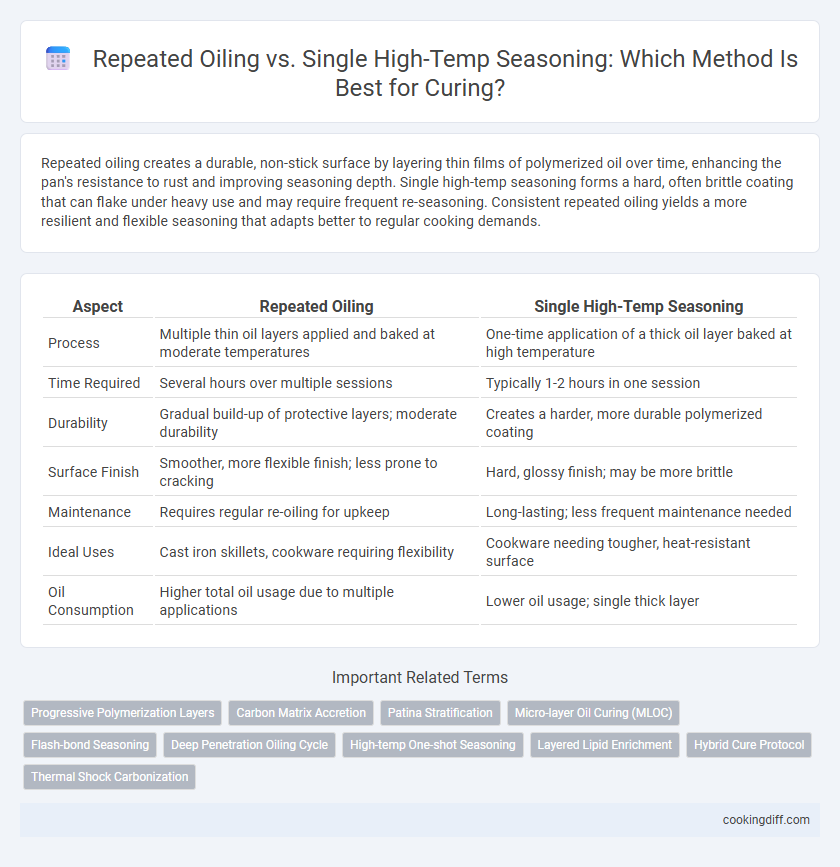

Table of Comparison

| Aspect | Repeated Oiling | Single High-Temp Seasoning |

|---|---|---|

| Process | Multiple thin oil layers applied and baked at moderate temperatures | One-time application of a thick oil layer baked at high temperature |

| Time Required | Several hours over multiple sessions | Typically 1-2 hours in one session |

| Durability | Gradual build-up of protective layers; moderate durability | Creates a harder, more durable polymerized coating |

| Surface Finish | Smoother, more flexible finish; less prone to cracking | Hard, glossy finish; may be more brittle |

| Maintenance | Requires regular re-oiling for upkeep | Long-lasting; less frequent maintenance needed |

| Ideal Uses | Cast iron skillets, cookware requiring flexibility | Cookware needing tougher, heat-resistant surface |

| Oil Consumption | Higher total oil usage due to multiple applications | Lower oil usage; single thick layer |

Introduction to Curing: Oiling vs High-Temp Seasoning

Curing cookware enhances its non-stick properties and durability by applying protective layers. Repeated oiling and single high-temperature seasoning are two primary methods used to achieve this effect.

- Repeated Oil Application - Involves multiple thin layers of oil baked onto the surface to build a durable, polymerized coating.

- Single High-Temperature Seasoning - Uses one intense heat session to rapidly bond oil molecules to the cookware's surface.

- Comparative Effectiveness - Repeated oiling creates a more resilient seasoning layer, while single seasoning offers speed but less long-term durability.

Science Behind Oil Polymerization in Cookware

Repeated oiling creates multiple thin layers of polymerized fat on cookware surfaces, enhancing non-stick properties through gradual build-up. Each oil layer undergoes thermal decomposition, forming a durable, carbonized film via free radical polymerization and cross-linking.

Single high-temperature seasoning causes rapid polymerization, producing a thicker, but potentially uneven and brittle, protective layer on the pan. The science behind oil polymerization involves heat-induced oxidation and polymer chain formation that chemically bonds to the metal surface, preventing rust and improving cooking performance.

Step-by-Step: Repeated Oiling Method

The Step-by-Step: Repeated Oiling Method involves applying multiple thin layers of oil to the cookware, allowing each layer to polymerize through heating before adding the next. This gradual buildup of seasoning enhances the non-stick surface and provides superior protection against rust compared to a single high-temp seasoning. Consistent repetition ensures deeper oil penetration and a more durable, long-lasting cure on cast iron or carbon steel pans.

Step-by-Step: Single High-Temperature Seasoning

Single high-temperature seasoning involves applying a thin layer of oil and heating the cookware to create a durable, non-stick surface in one intensive step. This method forms a hard polymerized coating that enhances rust resistance and durability compared to repeated oiling.

- Preparation - Clean the cookware thoroughly and dry it completely before applying a thin, even layer of high smoke point oil.

- Heating - Place the oiled cookware in an oven preheated to 450-500degF (232-260degC) for 1 hour to allow the oil to polymerize and bond to the surface.

- Cooling - Let the cookware cool inside the oven gradually to room temperature to prevent cracking and ensure a strong seasoning layer.

Durability & Longevity of Each Technique

Repeated oiling builds up multiple layers of polymerized oil, creating a flexible, durable seasoning that resists cracking over time. Single high-temp seasoning forms a harder, more brittle coating that can last longer initially but may chip with heavy use.

- Repeated oiling enhances flexibility - multiple thin layers prevent flaking and improve adhesion to the cookware surface.

- Single high-temp seasoning increases hardness - heat promotes deeper polymerization, resulting in a tough, protective layer.

- Durability depends on use - repeated oiling suits frequent cooking and maintenance, while high-temp seasoning suits infrequent heavy-duty applications.

Choosing between techniques depends on desired balance of longevity and ease of repair.

Comparing Nonstick Results: Which Method Wins?

Repeated oiling creates multiple thin protective layers that enhance nonstick properties over time. Single high-temp seasoning forms a durable, but sometimes uneven, coating that can be prone to flaking.

Repeated oiling provides a smoother, more uniform nonstick surface by allowing oils to polymerize incrementally. High-temp seasoning can achieve a harder crust but may require more maintenance to prevent chipping. Overall, repeated oiling often results in better long-term nonstick performance for cookware.

Maintenance Differences: Oiling vs High-Temp Cure

Repeated oiling maintains cast iron cookware by forming a thin, flexible protective layer that prevents rust and enhances seasoning over time. This method requires frequent application but allows for easy touch-ups and gradual buildup of seasoning.

Single high-temp seasoning involves heating the cookware at temperatures above 450degF to polymerize oil, creating a hard, durable coating. This process provides a more robust initial layer but demands less frequent maintenance compared to repeated oiling.

Best Oils for Each Curing Method

| Curing Method | Best Oils | Benefits |

|---|---|---|

| Repeated Oiling | Flaxseed oil, walnut oil, tung oil | These oils polymerize slowly, forming durable, flexible protective layers ideal for gradual, layered curing processes. |

| Single High-Temp Seasoning | Canola oil, grapeseed oil, vegetable oil | High smoke point oils withstand elevated temperatures, ensuring fast curing and robust seasoning without breaking down. |

Common Mistakes to Avoid During Curing

What are the common mistakes to avoid during curing when choosing between repeated oiling and single high-temp seasoning? Repeated oiling can lead to uneven seasoning if not properly absorbed, while single high-temp seasoning risks burning the oil, causing a sticky residue. Ensuring consistent temperature control and appropriate oil application prevents compromised durability and non-uniform surface texture.

Related Important Terms

Progressive Polymerization Layers

Repeated oiling during curing builds progressive polymerization layers that enhance the non-stick surface and durability of cookware, whereas a single high-temp seasoning creates a thicker but less uniform polymer layer prone to flaking and uneven curing. The gradual layering from multiple oil applications ensures a stronger, more resilient seasoning through incremental carbonization and cross-linking of oils.

Carbon Matrix Accretion

Repeated oiling promotes gradual carbon matrix accretion by allowing incremental polymerization and bonding of oil molecules to the metal surface, enhancing the durability and non-stick properties of the seasoning layer. Single high-temp seasoning rapidly forms a harder carbon matrix but risks uneven adhesion and micro-cracking, potentially compromising the curing quality compared to the more controlled buildup from multiple oiling cycles.

Patina Stratification

Repeated oiling during curing enhances patina stratification by building multiple thin layers of polymerized oil, creating a durable and evenly cured surface. In contrast, a single high-temp seasoning forms a thicker, less stratified patina, which may result in uneven curing and reduced long-term protection.

Micro-layer Oil Curing (MLOC)

Micro-layer Oil Curing (MLOC) leverages repeated oiling cycles to create durable, uniform micro-layers that enhance corrosion resistance and surface hardness better than single high-temperature seasoning methods. This technique optimizes oil polymerization at controlled temperatures, resulting in superior bonding and long-lasting protective coatings.

Flash-bond Seasoning

Flash-bond Seasoning uses a single high-temperature treatment that creates a durable, non-stick surface by chemically bonding oil to the cookware, outperforming repeated oiling methods which rely on multiple layers of polymerized oil. This single-step process eliminates the need for frequent reapplication and builds a more consistent, long-lasting seasoning layer ideal for efficient curing.

Deep Penetration Oiling Cycle

Deep Penetration Oiling Cycle enhances curing by repeatedly infusing oil into the material's pores, ensuring thorough saturation and long-lasting protection compared to a single high-temp seasoning. This method maximizes oil absorption, improving durability and resistance to wear through continuous deep-layer penetration.

High-temp One-shot Seasoning

High-temp one-shot seasoning creates a durable, non-stick patina by polymerizing oil at temperatures above 450degF, forming a hard, protective layer in a single application. This method outperforms repeated oiling by reducing seasoning time and improving resistance to rust and wear on cast iron and carbon steel cookware.

Layered Lipid Enrichment

Repeated oiling enhances layered lipid enrichment by gradually building multiple protective barrier layers within the seasoning, improving durability and chemical resistance. Single high-temperature seasoning creates a uniform lipid layer quickly but lacks the depth and resilience provided by incremental oil absorption and polymerization.

Hybrid Cure Protocol

Hybrid Cure Protocol combines repeated oiling with a single high-temperature seasoning to enhance the durability and non-stick properties of cookware. This method balances the thorough penetration of oil layers with the structural hardening from heat, resulting in superior surface protection and extended lifespan.

Repeated oiling vs single high-temp seasoning for curing. Infographic

cookingdiff.com

cookingdiff.com