High smoke point oils, such as grapeseed or avocado oil, are ideal for curing utensils because they withstand elevated temperatures without breaking down, ensuring effective polymerization of the oil on wood surfaces. Specialty blend oils often combine various natural oils to enhance durability and provide a balanced curing process, offering protection and longevity tailored for specific utensils. Choosing the right oil depends on the utensil's material and intended use, with high smoke point oils preferred for more heat-exposed items and specialty blends for general maintenance.

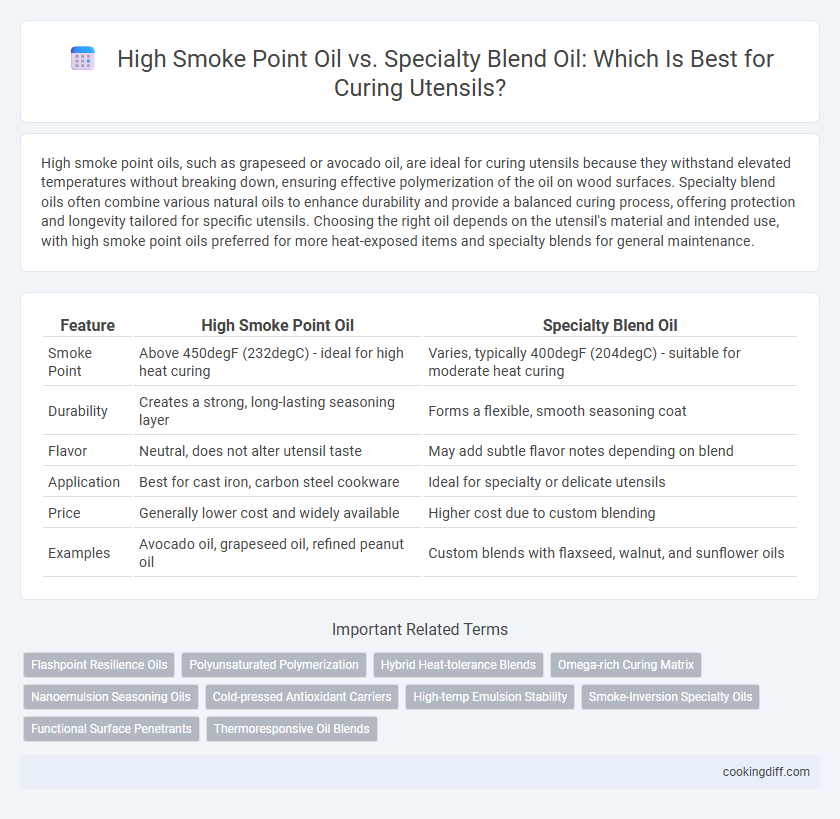

Table of Comparison

| Feature | High Smoke Point Oil | Specialty Blend Oil |

|---|---|---|

| Smoke Point | Above 450degF (232degC) - ideal for high heat curing | Varies, typically 400degF (204degC) - suitable for moderate heat curing |

| Durability | Creates a strong, long-lasting seasoning layer | Forms a flexible, smooth seasoning coat |

| Flavor | Neutral, does not alter utensil taste | May add subtle flavor notes depending on blend |

| Application | Best for cast iron, carbon steel cookware | Ideal for specialty or delicate utensils |

| Price | Generally lower cost and widely available | Higher cost due to custom blending |

| Examples | Avocado oil, grapeseed oil, refined peanut oil | Custom blends with flaxseed, walnut, and sunflower oils |

Understanding the Role of Oils in Utensil Curing

High smoke point oils, such as grapeseed or avocado oil, are preferred for utensil curing due to their ability to withstand high temperatures without breaking down, ensuring a durable seasoning layer. Specialty blend oils often combine multiple oils to balance smoke point and polymerization properties, enhancing the curing process for long-lasting non-stick surfaces.

Choosing the right oil affects the polymerization and bonding of the oil to the utensil's surface, which is critical for rust prevention and improved cooking performance. Understanding the chemical stability and smoke points of different oils helps optimize the curing process, resulting in smoother, more resilient cookware coatings.

What is High Smoke Point Oil?

| High smoke point oil is a type of cooking oil that can withstand elevated temperatures without breaking down or producing smoke, making it ideal for curing utensils. Common examples include avocado oil, refined safflower oil, and grapeseed oil, with smoke points typically above 400degF (204degC). Using high smoke point oils ensures a durable, non-stick surface by effectively polymerizing the oil on cookware without harmful smoke or residue. |

Exploring Specialty Blend Oils for Curing

Specialty blend oils combine high smoke point oils with natural antioxidants, enhancing durability and preventing polymerization during utensil curing. These blends offer superior heat resistance compared to traditional high smoke point oils alone, resulting in a more resilient, non-stick surface on cast iron and carbon steel cookware. Their tailored fatty acid profiles optimize curing efficiency, reducing sticky residues and extending utensil lifespan.

Benefits of High Smoke Point Oils in Curing Utensils

High smoke point oils like grapeseed, avocado, and refined safflower oil provide superior durability when curing utensils due to their ability to withstand intense heat without breaking down. These oils form a strong, long-lasting protective layer that reduces stickiness and enhances the seasoning on cast iron, carbon steel, and other cookware. Specialty blend oils often contain lower smoke point components that can degrade under high heat, compromising the curing process and the utensil's longevity.

Advantages of Using Specialty Blend Oils

Specialty blend oils offer a balanced combination of fatty acids that promote superior polymerization during utensil curing, enhancing non-stick surfaces and durability. Their tailored composition often results in less smoke and odor compared to high smoke point oils, making the curing process cleaner and more efficient.

- Enhanced Polymerization - Specialty blends create a stronger, more resilient seasoning layer on utensils.

- Reduced Smoke Production - Lower irritation and cleaner air quality during the curing process.

- Customized Fatty Acid Profile - Optimizes curing for different types of cookware materials.

Using specialty blend oils ensures a high-performance seasoning with improved longevity and user experience.

Smoke Point: Why It Matters for Utensil Curing

High smoke point oils are preferred for utensil curing because they withstand higher temperatures without breaking down, preserving the integrity of the seasoning layer. Specialty blend oils often contain components with varying smoke points, which can cause uneven curing and potential residue buildup.

- Smoke Point Determines Stability - Oils with higher smoke points remain stable under heat, ensuring a durable and non-toxic seasoning layer on utensils.

- Prevents Harmful Residues - Using oils with low smoke points can lead to polymerization breakdown, resulting in sticky or flaky residue on cured cookware.

- Enhances Curing Efficiency - High smoke point oils polymerize effectively, forming a hard, protective surface that extends the lifespan of cooking utensils.

Comparing Durability: High Smoke Point vs Specialty Blends

High smoke point oils such as grapeseed or avocado oil provide superior durability when curing utensils due to their stability at elevated temperatures, reducing the risk of breakdown and rancidity. Specialty blend oils, often formulated with a mix of mediums for enhanced polymerization, offer tailored curing properties but may lack the heat resistance of single high smoke point oils.

The high smoke point oils withstand prolonged exposure to heat during the curing process, creating a robust, long-lasting protective layer on cooking utensils. Specialty blends can deliver faster curing times and improved surface hardness, benefiting items needing swift seasoning. However, they may degrade quicker under sustained high heat, making them less durable compared to pure high smoke point oils.

Flavor Transfer: Impact on Cooking Utensils

High smoke point oils minimize flavor transfer during curing, preserving the original taste of food cooked in seasoned utensils. Specialty blend oils may introduce subtle flavor notes that enhance the cookware's seasoning profile over time.

- High Smoke Point Oils Enhance Neutrality - Oils like avocado or grapeseed withstand high heat without breaking down, preventing unwanted flavors from transferring to food.

- Specialty Blend Oils Add Complex Flavor - Blended oils often contain nutty or herbal components that subtly infuse the utensil's surface with distinctive aromas.

- Flavor Transfer Affects Culinary Versatility - Choosing an oil impacts whether utensils impart a consistent neutrality or a developing flavor complexity in cooking.

Cost and Accessibility Considerations

Which type of oil offers better cost efficiency and accessibility for curing utensils? High smoke point oils, such as canola or grapeseed oil, are generally more affordable and widely available in most markets, making them a practical choice for everyday use. Specialty blend oils often come with a higher price tag and limited availability, but they may provide enhanced performance for specific curing needs.

Related Important Terms

Flashpoint Resilience Oils

High smoke point oils, such as avocado or grapeseed oil, offer superior flashpoint resilience ideal for curing utensils as they withstand higher temperatures without breaking down, ensuring durable, non-stick seasoning layers. Specialty blend oils combine the benefits of multiple oils to enhance oxidation stability and flashpoint resistance, optimizing the curing process by preventing polymerization issues and extending utensil lifespan.

Polyunsaturated Polymerization

High smoke point oils, such as refined avocado or grapeseed oil, resist breakdown and facilitate stable polyunsaturated polymerization during utensil curing, leading to a durable, non-stick seasoning layer. Specialty blend oils often combine polyunsaturated and monounsaturated fats but may vary in polymerization efficiency, affecting the seasoning's durability and resistance to smoke damage.

Hybrid Heat-tolerance Blends

Hybrid heat-tolerance blends in curing utensils combine high smoke point oils, such as refined avocado or grapeseed oil, with specialty oils rich in antioxidants, ensuring optimal thermal stability and enhanced seasoning durability. These blends minimize polymerization breakdown, providing a robust, non-stick surface resistant to high-temperature degradation and extending the life of cast iron and carbon steel cookware.

Omega-rich Curing Matrix

High smoke point oils, such as refined avocado or safflower oil, provide a stable, omega-rich curing matrix that prevents polymer breakdown during utensil seasoning, ensuring durable non-stick surfaces. Specialty blend oils combine varied omega fatty acids that enhance the curing layer's flexibility and longevity, optimizing utensil performance under high-heat conditions.

Nanoemulsion Seasoning Oils

Nanoemulsion seasoning oils with high smoke points such as avocado or refined sunflower oil enhance curing durability by forming stable, oxidation-resistant coatings on utensils. Specialty blend oils designed for nanoemulsions optimize lipid dispersion and penetration, improving seasoning uniformity and extending utensil lifespan.

Cold-pressed Antioxidant Carriers

Cold-pressed antioxidant carriers in specialty blend oils offer superior protection during curing by minimizing oxidation and extending utensil lifespan compared to high smoke point oils, which may degrade faster under prolonged heat exposure. The natural antioxidants in cold-pressed oils enhance curing efficiency and maintain the integrity of cooking utensils by providing a stable, nutrient-rich layer resistant to smoke and thermal breakdown.

High-temp Emulsion Stability

High smoke point oils, such as avocado or refined grapeseed oil, provide superior high-temperature emulsion stability, making them ideal for curing utensils by preventing breakdown and ensuring a durable, non-stick coating. Specialty blend oils often contain lower smoke point components that can degrade faster under heat, reducing the effectiveness and longevity of the cured surface.

Smoke-Inversion Specialty Oils

Smoke-inversion specialty oils, formulated with high smoke point components and antioxidants, provide superior thermal stability during curing, resulting in enhanced utensil durability and resistance to carbon buildup. In contrast, conventional high smoke point oils primarily offer heat tolerance but lack the protective properties that reduce smoke production and improve seasoning quality.

Functional Surface Penetrants

High smoke point oils, such as flaxseed or grapeseed oil, penetrate utensil surfaces effectively, creating durable, non-stick seasoning layers while resisting polymer breakdown under high heat. Specialty blend oils often combine multiple fatty acids tailored for enhanced surface adhesion and oxidation stability, optimizing long-term curing performance and functional durability.

High Smoke Point Oil vs Specialty Blend Oil for curing utensils. Infographic

cookingdiff.com

cookingdiff.com