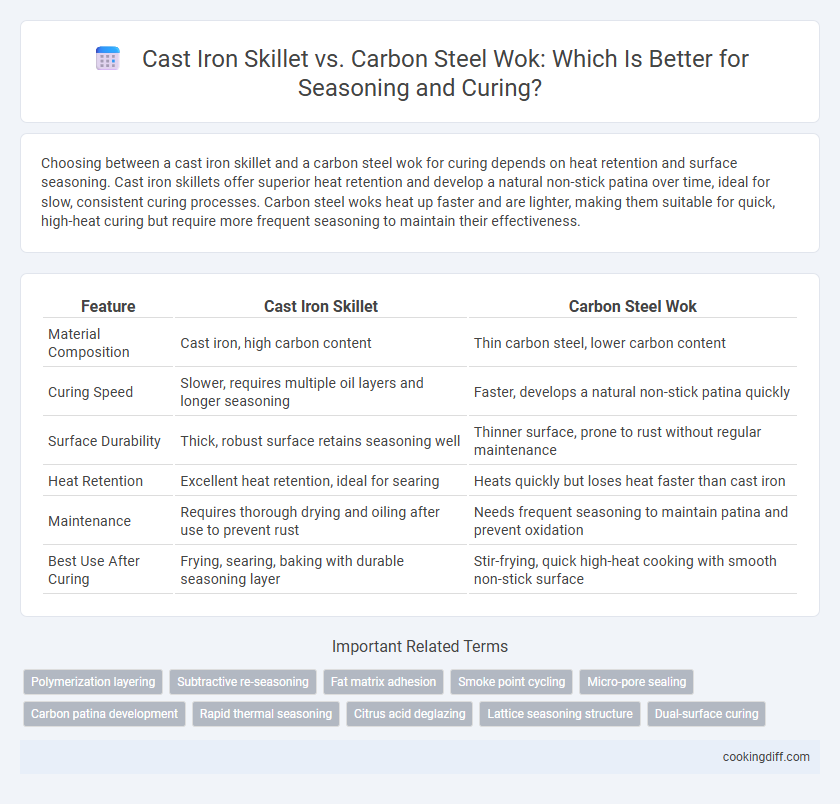

Choosing between a cast iron skillet and a carbon steel wok for curing depends on heat retention and surface seasoning. Cast iron skillets offer superior heat retention and develop a natural non-stick patina over time, ideal for slow, consistent curing processes. Carbon steel woks heat up faster and are lighter, making them suitable for quick, high-heat curing but require more frequent seasoning to maintain their effectiveness.

Table of Comparison

| Feature | Cast Iron Skillet | Carbon Steel Wok |

|---|---|---|

| Material Composition | Cast iron, high carbon content | Thin carbon steel, lower carbon content |

| Curing Speed | Slower, requires multiple oil layers and longer seasoning | Faster, develops a natural non-stick patina quickly |

| Surface Durability | Thick, robust surface retains seasoning well | Thinner surface, prone to rust without regular maintenance |

| Heat Retention | Excellent heat retention, ideal for searing | Heats quickly but loses heat faster than cast iron |

| Maintenance | Requires thorough drying and oiling after use to prevent rust | Needs frequent seasoning to maintain patina and prevent oxidation |

| Best Use After Curing | Frying, searing, baking with durable seasoning layer | Stir-frying, quick high-heat cooking with smooth non-stick surface |

Introduction to Curing in Cookware

Curing cookware creates a natural, non-stick surface and prevents rust by polymerizing oils under heat. Cast iron skillets and carbon steel woks both benefit from curing but differ in surface texture and maintenance needs.

- Cast Iron Skillet Curing - This process builds a thick, durable seasoning layer that enhances heat retention and prevents food from sticking.

- Carbon Steel Wok Curing - The seasoning is thinner and more delicate, requiring frequent re-oiling to maintain a smooth, rust-resistant surface.

- Curing Temperature and Oils - Optimal curing uses high smoke point oils like flaxseed or grapeseed, with temperatures around 400degF to 500degF to ensure polymerization.

Cast Iron Skillets: Overview and Curing Benefits

Cast iron skillets offer superior heat retention and even distribution, making them ideal for achieving a durable seasoning layer during the curing process. Their porous surface absorbs oils deeply, enhancing non-stick properties and preventing rust over time. Regular curing of cast iron skillets develops a natural, long-lasting patina that improves cooking performance and durability.

Carbon Steel Woks: Overview and Curing Benefits

Carbon steel woks offer superior heat responsiveness and durability, making them ideal for high-temperature cooking. Their porous surface improves with seasoning, creating a natural non-stick layer that enhances flavor over time. Proper curing of carbon steel woks prevents rust and ensures even heat distribution for optimal culinary performance.

Surface Differences: How Cast Iron and Carbon Steel Affect Curing

Cast iron skillets develop a dense, polymerized seasoning layer due to their porous surface, enhancing non-stick properties and rust resistance during curing. Carbon steel woks have a smoother surface with fewer pores, resulting in a thinner seasoning layer that forms more quickly but may require frequent maintenance to maintain durability.

The microstructure of cast iron traps oils more effectively, creating a robust curing film that improves over time with repeated use. In contrast, carbon steel's rapid heat conduction allows faster polymerization of oils, accelerating the curing process but yielding a seasoning that is more susceptible to wear under high-heat cooking.

Heat Retention and Distribution: Curing Implications

Cast iron skillets excel in heat retention, maintaining steady temperatures essential for thorough curing, while carbon steel woks distribute heat more evenly but cool faster. This difference impacts the curing process, as cast iron's consistent heat ensures a more uniform polymerization of seasoning layers.

Carbon steel woks heat rapidly and respond quickly to temperature changes, which can lead to uneven curing if not carefully managed. Cast iron's slower heat response with superior heat retention promotes deeper seasoning bonds but requires longer heating times. Proper curing enhances the skillet's non-stick properties and durability by forming a robust, heat-resistant patina.

Step-by-Step Curing Process for Cast Iron Skillets

Curing a cast iron skillet involves a specific process to create a durable, non-stick seasoning layer that enhances cooking performance and prevents rust. This method differs from seasoning a carbon steel wok, which typically requires faster, high-heat treatments due to its thinner metal construction.

- Clean Skillet Thoroughly - Remove any factory coating or rust by scrubbing with soap and warm water, then dry completely.

- Apply Thin Oil Layer - Coat the entire skillet surface with a thin layer of high-smoke-point oil such as flaxseed or grapeseed oil.

- Bake at High Temperature - Place the skillet upside down in an oven preheated to 450-500degF for one hour and let it cool inside the oven.

Repeated oil application and baking cycles build protective seasoning layers essential for optimal cast iron skillet usage.

Step-by-Step Curing Process for Carbon Steel Woks

Carbon steel woks require a precise curing process to develop a natural non-stick surface and protect against rust. This process differs from cast iron skillets due to the wok's thinner metal and unique shape, necessitating specialized steps.

- Clean the wok thoroughly - Remove factory coatings and any residues using hot water and a gentle scrub, avoiding soap to preserve the natural surface.

- Heat the wok evenly - Place the wok on high heat until it starts to smoke, which opens the metal's pores for oil absorption.

- Apply thin layers of oil - Rub a high-smoke-point oil like flaxseed or grapeseed oil over the interior and heat repeatedly until a dark, smooth patina forms, indicating a well-cured surface.

Maintenance Tips After Curing: Cast Iron vs Carbon Steel

| Maintenance Tips After Curing | Cast Iron | Carbon Steel |

| Cleaning Method | Use warm water without soap; avoid soaking to prevent rust. | Rinse with hot water and use a soft brush; avoid harsh detergents. |

| Drying | Thoroughly dry with a towel and heat on stove to remove moisture. | Wipe dry immediately and heat quickly to prevent oxidation. |

| Oiling | Apply a thin layer of vegetable oil after each use to maintain seasoning. | Lightly coat with oil to protect surface and enhance patina. |

| Storage | Store in a dry place with a paper towel inside to absorb moisture. | Keep in a well-ventilated area to avoid rust buildup. |

Common Curing Mistakes and How to Avoid Them

What are common curing mistakes when seasoning a cast iron skillet versus a carbon steel wok? Overheating the pan or applying too much oil can lead to sticky, uneven seasoning on both cast iron and carbon steel. Avoid these issues by using moderate heat and thin, even layers of oil to create a durable, non-stick surface.

Related Important Terms

Polymerization layering

Polymerization layering during curing creates a durable, non-stick surface by bonding oils to cast iron skillets, enhancing rust resistance and cooking performance. Carbon steel woks develop a thinner, more flexible polymerized layer due to their higher thermal conductivity, allowing quicker seasoning but requiring more frequent maintenance to preserve the protective coating.

Subtractive re-seasoning

Cast iron skillets require more frequent subtractive re-seasoning due to their porous surface which can develop rust or uneven seasoning layers over time, making the removal of old seasoning essential for optimal non-stick performance. Carbon steel woks, with their smoother surface and faster heat response, benefit from less aggressive subtractive re-seasoning methods, preserving their natural patina while maintaining durability and enhanced seasoning adhesion.

Fat matrix adhesion

Cast iron skillets develop a thicker, more porous seasoning layer that enhances fat matrix adhesion due to their higher carbon content and rougher surface texture. Carbon steel woks offer a smoother finish that results in a thinner seasoning layer, providing less fat matrix adherence but allowing quicker re-seasoning and easier maintenance.

Smoke point cycling

Cast iron skillets withstand prolonged smoke point cycling due to their high heat retention and even heating properties, allowing for thorough seasoning during curing without frequent reapplication. Carbon steel woks, while responsive to heat changes and quicker to reach smoke points, require more frequent smoke point cycling to build a durable cured layer, as their thinner material heats and cools rapidly.

Micro-pore sealing

Cast iron skillets offer superior micro-pore sealing during curing due to their dense material composition, resulting in enhanced seasoning retention and rust resistance. Carbon steel woks, while quicker to season, have larger micro-pores that require more frequent maintenance to maintain an effective non-stick surface.

Carbon patina development

Carbon steel woks develop a faster and more resilient carbon patina during curing due to their thinner gauge and smoother surface, which allows for even heat distribution and quicker polymerization of seasoning oils. In contrast, cast iron skillets require longer curing times to build a comparable patina because of their porous texture and thicker metal composition, which absorbs oils more slowly and promotes uneven seasoning layers.

Rapid thermal seasoning

Cast iron skillets and carbon steel woks both benefit from rapid thermal seasoning, but carbon steel woks heat up faster due to their thinner material, allowing for quicker polymerization of oil and a more efficient curing process. Cast iron skillets, with their thicker walls, retain heat longer, promoting even seasoning but requiring extended time to reach optimal temperatures for rapid thermal curing.

Citrus acid deglazing

Cast iron skillets develop a durable seasoning layer ideal for curing with citrus acid deglazing, as the porous surface retains flavors and enhances the skillet's non-stick properties. Carbon steel woks, with their thinner walls and smoother surfaces, respond well to citrus acid deglazing by quickly removing residues, enabling faster seasoning cycles and maintaining a reactive cooking surface.

Lattice seasoning structure

A cast iron skillet develops a dense, porous lattice seasoning structure that enhances oil polymerization and provides superior non-stick properties over time. In contrast, a carbon steel wok forms a thinner, more flexible seasoning layer that allows for quicker heat responsiveness but may require more frequent maintenance to maintain its lattice integrity.

Cast iron skillet vs carbon steel wok for curing. Infographic

cookingdiff.com

cookingdiff.com