Seasoned cast iron retains heat evenly and develops a natural non-stick surface over time, making it ideal for slow, consistent curing processes. Blue carbon steel heats up quickly and responds rapidly to temperature changes, offering greater control during curing but requiring frequent seasoning to maintain its non-stick properties. Choosing between the two depends on whether steady heat retention or quick thermal response is more critical for your curing technique.

Table of Comparison

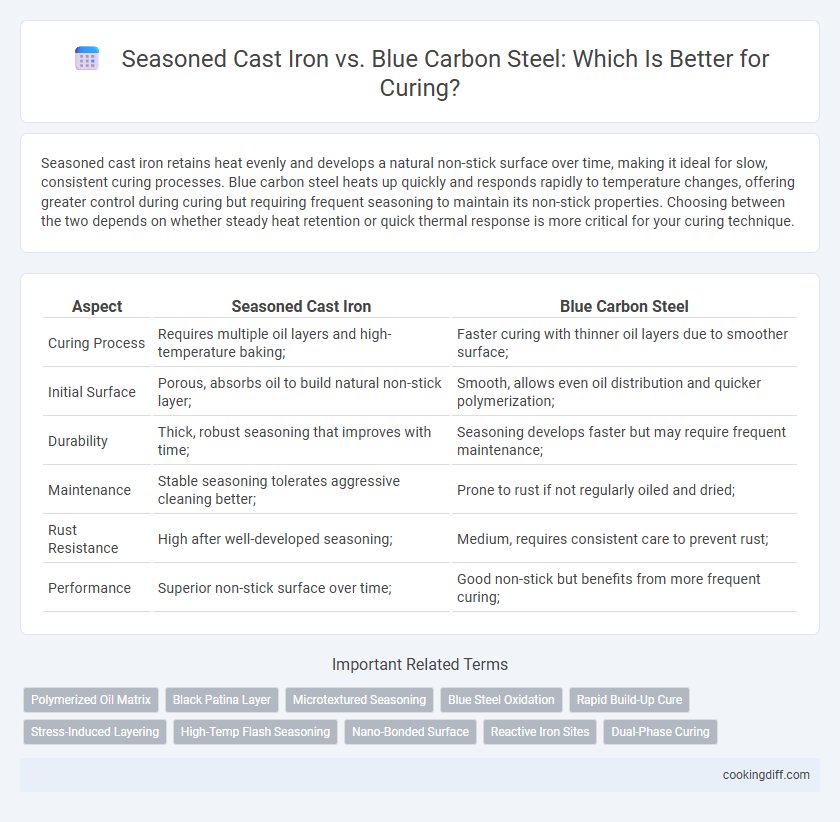

| Aspect | Seasoned Cast Iron | Blue Carbon Steel |

|---|---|---|

| Curing Process | Requires multiple oil layers and high-temperature baking; | Faster curing with thinner oil layers due to smoother surface; |

| Initial Surface | Porous, absorbs oil to build natural non-stick layer; | Smooth, allows even oil distribution and quicker polymerization; |

| Durability | Thick, robust seasoning that improves with time; | Seasoning develops faster but may require frequent maintenance; |

| Maintenance | Stable seasoning tolerates aggressive cleaning better; | Prone to rust if not regularly oiled and dried; |

| Rust Resistance | High after well-developed seasoning; | Medium, requires consistent care to prevent rust; |

| Performance | Superior non-stick surface over time; | Good non-stick but benefits from more frequent curing; |

Introduction to Curing: Seasoned Cast Iron vs Blue Carbon Steel

Seasoned cast iron develops a natural non-stick surface through polymerized oil layers, enhancing durability and corrosion resistance during curing. Blue carbon steel requires regular seasoning to build a protective patina that prevents rust and improves cooking performance over time. Both materials benefit from curing processes that involve heat and oil to maintain their longevity and functionality in the kitchen.

What is Cast Iron Seasoning?

What is cast iron seasoning and how does it affect cookware performance? Cast iron seasoning involves applying a layer of polymerized oil that creates a non-stick surface and prevents rust. This process enhances durability and improves cooking by filling microscopic pores in the metal, making it ideal for seasoned cast iron cookware compared to blue carbon steel.

Understanding Blue Carbon Steel Curing

Blue carbon steel requires a careful curing process to develop its natural non-stick patina and prevent rust. The steel's high carbon content allows it to harden through seasoning, creating a durable, blackened surface that improves with regular use.

Unlike seasoned cast iron, blue carbon steel cures faster due to its thinner gauge and smoother texture, which helps oils polymerize efficiently. Proper curing involves multiple thin layers of oil baked at high temperatures, forming a protective coating essential for long-lasting performance.

Material Differences: Cast Iron vs Blue Carbon Steel

Seasoned cast iron develops a natural non-stick surface through polymerized oils that penetrate its porous structure, enhancing durability and heat retention. Blue carbon steel forms a thinner, smoother seasoning layer that requires more frequent maintenance but offers quicker heating and lighter weight compared to cast iron.

Cast iron's dense composition absorbs and distributes heat evenly, making it ideal for slow, steady cooking and long-lasting seasoning. Blue carbon steel's tighter grain structure demands careful curing to prevent rust yet provides superior responsiveness to temperature changes. Both materials benefit from regular oil curing, but blue carbon steel requires more frequent reapplication to maintain its protective patina.

Heat Retention and Distribution in Curing

| Seasoned Cast Iron excels in heat retention, maintaining consistent temperatures ideal for slow curing processes. Its dense material allows uniform heat distribution, preventing hotspots and ensuring even curing. The seasoned surface also enhances non-stick properties, facilitating better moisture control during heat application. |

| Blue Carbon Steel heats up rapidly due to its thinner gauge, but retains heat less effectively than cast iron, which may cause temperature fluctuations in curing. Heat distribution is quicker but less uniform, making it better suited for fast, high-heat curing methods rather than prolonged heat exposure. The bare surface requires regular seasoning to maintain optimal curing performance and prevent rust. |

Durability and Longevity in Seasoned Cookware

Seasoned cast iron boasts exceptional durability due to its thick, sturdy composition and ability to develop a resilient, non-stick seasoning layer over time. This longevity makes it ideal for frequent use and high-heat cooking without compromising the cookware's integrity.

Blue carbon steel, while durable, is thinner and requires more maintenance to preserve its seasoning and prevent rusting. Its lightweight nature enhances handling but may reduce lifespan compared to the robust, long-lasting seasoned cast iron.

Maintenance and Re-seasoning: Cast Iron vs Carbon Steel

Seasoned cast iron requires less frequent re-seasoning due to its porous surface that retains oil more effectively. Blue carbon steel demands more regular maintenance and re-seasoning to prevent rust and maintain its non-stick properties.

- Durability of seasoning - Cast iron's thicker seasoning layer withstands heavy use better than blue carbon steel's thinner coating.

- Rust resistance - Cast iron is more resilient to rust once well-seasoned, while blue carbon steel needs diligent drying and oiling.

- Maintenance routine - Blue carbon steel requires more frequent oil application and heat treatments to maintain optimal seasoning.

Proper maintenance extends the lifespan and cooking performance of both seasoned cast iron and blue carbon steel cookware.

Cooking Performance: Which Cured Surface Wins?

Seasoned cast iron offers a robust, non-stick surface ideal for high-heat cooking and retains heat evenly, enhancing searing and frying performance. Blue carbon steel cures faster and develops a smoother patina, providing excellent thermal conductivity and lighter weight for quick temperature changes. In terms of cooking performance, seasoned cast iron delivers superior heat retention, while blue carbon steel excels in responsiveness and ease of seasoning maintenance.

Cost and Accessibility: Choosing the Right Pan

Seasoned cast iron pans usually have a higher upfront cost but offer widespread availability and long-term durability. Blue carbon steel pans tend to be more affordable and lightweight but might require more frequent maintenance and special attention during curing.

- Cost Efficiency - Blue carbon steel pans are generally cheaper, making them accessible for beginners or budget-conscious cooks.

- Availability - Seasoned cast iron cookware is more commonly found in retail stores and online, ensuring easier access.

- Long-Term Value - Cast iron's durability and seasoning stability provide greater long-term value despite the initial higher price.

Related Important Terms

Polymerized Oil Matrix

Seasoned cast iron develops a durable polymerized oil matrix through repeated heating and oil application, creating a non-stick and rust-resistant surface ideal for curing. Blue carbon steel also forms a similar polymerized layer but often requires more frequent maintenance to maintain its protective seasoning due to its higher susceptibility to oxidation.

Black Patina Layer

Seasoned cast iron develops a durable black patina layer through polymerized oil layers that enhance non-stick properties and rust resistance. Blue carbon steel forms a thinner, more reactive black patina that may require more frequent maintenance but achieves a faster curing process and improved heat responsiveness.

Microtextured Seasoning

Microtextured seasoning on blue carbon steel creates a finer, more uniform non-stick surface compared to the traditional seasoning layer on seasoned cast iron, enhancing food release and durability. Blue carbon steel's microtextured finish accelerates polymerization during curing, resulting in a more resilient and corrosion-resistant patina.

Blue Steel Oxidation

Blue carbon steel develops a durable, natural patina through a process of controlled oxidation during curing, enhancing its non-stick properties and rust resistance without the need for seasoning layers typical of cast iron. This oxide layer forms a protective barrier that maintains the steel's structural integrity and improves flavor retention, distinguishing it from the heavier, porous surface of seasoned cast iron.

Rapid Build-Up Cure

Seasoned cast iron features a dense, porous surface that enables a rapid build-up cure through repeated seasoning layers, enhancing its non-stick properties and durability. Blue carbon steel, with its smoother surface and quicker heat response, develops a faster initial cure but requires more frequent maintenance to sustain its seasoning layer.

Stress-Induced Layering

Seasoned cast iron develops a durable, stress-induced oxide layer through repeated heating and oil polymerization, creating a natural non-stick surface resistant to wear and corrosion. Blue carbon steel forms a thinner, stress-induced oxide layer with higher susceptibility to flaking, requiring more frequent re-curing to maintain optimal protection and seasoning quality.

High-Temp Flash Seasoning

Seasoned cast iron develops a durable non-stick layer through polymerized oils that withstand high temperatures during flash seasoning, enhancing its thermal retention and corrosion resistance. Blue carbon steel, while also capable of high-temp flash seasoning, forms a thinner patina that requires more frequent maintenance but heats up faster and offers lighter weight for improved handling.

Nano-Bonded Surface

Seasoned cast iron features a durable nano-bonded surface formed from polymerized oils embedded into the iron pores, offering superior non-stick properties and rust resistance during curing. Blue carbon steel develops a thinner nano-bonded oxide layer through heat treatment, enhancing seasoning stability and corrosion resistance while maintaining a lighter, faster-heating cookware profile.

Reactive Iron Sites

Seasoned cast iron develops a stable layer of polymerized oil that fills and protects reactive iron sites, creating a durable non-stick surface resistant to rust and food adhesion. Blue carbon steel, with its higher reactive iron content, requires more frequent curing to maintain this protective layer, as its surface oxidizes faster but offers superior heat responsiveness and seasoning depth.

Seasoned Cast Iron vs Blue Carbon Steel for curing. Infographic

cookingdiff.com

cookingdiff.com