A Dutch oven offers superior heat retention and even cooking, making it ideal for slow curing processes that require consistent temperatures. Raw steel skillets heat quickly and respond faster to temperature changes, providing better control for shorter curing times but may risk uneven heat distribution. Choosing between them depends on the curing method's temperature stability and duration needs.

Table of Comparison

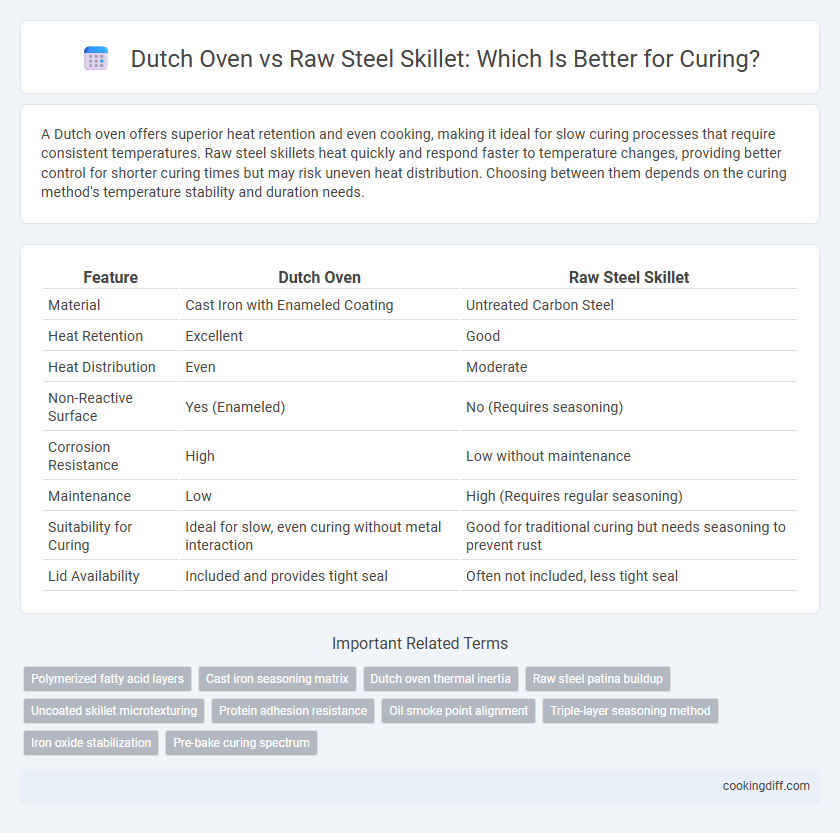

| Feature | Dutch Oven | Raw Steel Skillet |

|---|---|---|

| Material | Cast Iron with Enameled Coating | Untreated Carbon Steel |

| Heat Retention | Excellent | Good |

| Heat Distribution | Even | Moderate |

| Non-Reactive Surface | Yes (Enameled) | No (Requires seasoning) |

| Corrosion Resistance | High | Low without maintenance |

| Maintenance | Low | High (Requires regular seasoning) |

| Suitability for Curing | Ideal for slow, even curing without metal interaction | Good for traditional curing but needs seasoning to prevent rust |

| Lid Availability | Included and provides tight seal | Often not included, less tight seal |

Introduction to Curing: Dutch Oven vs Raw Steel Skillet

| Dutch Oven | Retains consistent heat and moisture, ideal for slow curing processes that require even temperature distribution to prevent drying out. |

| Raw Steel Skillet | Offers quicker heat transfer and can develop a natural seasoning layer, but may produce uneven curing results due to localized hot spots. |

| Curing Efficiency | Dutch ovens excel in maintaining a stable curing environment, while raw steel skillets demand more attention to temperature control for optimal results. |

Material Differences: Dutch Oven and Raw Steel Skillet Explained

Dutch ovens are typically made of cast iron and coated with enamel, offering excellent heat retention and even cooking, which is beneficial for slow curing processes. Raw steel skillets, being uncoated and thinner, heat up quickly but may cause uneven temperature distribution during curing.

- Heat Retention - Dutch ovens maintain steady heat for prolonged curing, preventing temperature fluctuations.

- Surface Reactivity - Raw steel skillets can react with acidic ingredients during curing, potentially affecting flavor and safety.

- Durability - Raw steel skillets develop a natural seasoning layer over time, while enamel coatings on Dutch ovens require careful handling to avoid chipping.

Choosing between these materials depends on curing method, temperature control, and desired flavor outcomes.

Heat Retention in Curing: Dutch Oven vs Raw Steel Skillet

Dutch ovens offer superior heat retention due to their thick cast iron walls and enamel coating, maintaining consistent temperature crucial for curing processes. Raw steel skillets heat up quickly but lose heat faster, leading to less stable curing conditions. Consistent heat retention in a Dutch oven ensures even curing and prevents temperature fluctuations that can affect food texture and safety.

Seasoning Process: Optimal Techniques for Each Cookware

The seasoning process for a Dutch oven involves applying a thin layer of oil and baking it at high temperatures to create a durable, non-stick coating that enhances its curing performance. In contrast, raw steel skillets require repeated cycles of oiling and heating to build up a natural patina that improves with use. Both methods optimize the cookware's ability to resist rust and develop flavor-enhancing properties essential for effective curing.

Durability and Longevity in Curing Performance

Dutch ovens, made from enameled cast iron, offer exceptional heat retention and durability, making them ideal for consistent curing processes that require steady temperatures. Their sealed surface prevents rust and minimizes maintenance, enhancing longevity in curing applications.

Raw steel skillets excel in heat conductivity and develop a naturally non-stick surface with seasoning, but they require regular care to prevent rust and maintain performance. Their durability depends on proper maintenance, which can limit long-term reliability compared to the more resilient Dutch oven in curing environments.

Flavor Development: Impact of Dutch Oven and Raw Steel Skillet

The Dutch oven's heavy, thick walls provide consistent heat retention and even cooking temperatures, which enhance flavor development during curing by allowing spices and herbs to infuse deeply. In contrast, a raw steel skillet heats quickly and unevenly, potentially causing hotspots that can scorch ingredients and inhibit balanced flavor extraction.

Flavor development in curing is significantly influenced by the cookware's heat distribution properties. Dutch ovens create a stable cooking environment that promotes slow, controlled flavor melding and moisture retention, essential for rich, complex tastes. Raw steel skillets, while responsive, require constant temperature control to prevent burning and uneven curing, often resulting in less nuanced flavor profiles.

Maintenance and Cleaning During Curing

Maintenance and cleaning during curing differ significantly between a Dutch oven and a raw steel skillet due to their material properties. Proper care ensures optimal seasoning development and prevents rust or damage.

- Dutch oven resists sticking - Its enameled coating reduces the need for intensive scrubbing, preserving the curing surface.

- Raw steel skillet requires thorough drying - Immediate drying after washing prevents rust and maintains the skillet's integrity during curing.

- Seasoning buildup management - Both cookware types benefit from gentle cleaning with minimal soap to maintain and build effective seasoning layers.

Versatility in Curing Applications

Which cookware offers greater versatility in curing applications, a Dutch oven or a raw steel skillet? Dutch ovens provide superior heat retention and even distribution, making them ideal for slow curing processes that require consistent temperature. Raw steel skillets excel in quick curing tasks due to their rapid heat response and ease of handling, though they may require more attention to maintain steady heat.

Common Curing Mistakes with Dutch Oven and Raw Steel Skillet

Using a Dutch oven for curing often leads to uneven heat distribution, causing inconsistent results and potential bacterial growth on the surface of the food. Raw steel skillets, while providing better heat conduction, are prone to rust if not properly seasoned and maintained during the curing process.

Common curing mistakes include failing to monitor temperature and humidity accurately in both Dutch ovens and raw steel skillets, which can compromise safety and flavor development. Neglecting to clean and dry these tools thoroughly after each use increases the risk of contamination and spoilage during curing.

Related Important Terms

Polymerized fatty acid layers

Dutch ovens develop a durable polymerized fatty acid layer through repeated heating and seasoning, enhancing their natural non-stick and rust-resistant properties ideal for curing. Raw steel skillets require more intensive seasoning to build similar polymerized coatings, making Dutch ovens superior for consistent curing performance with less maintenance.

Cast iron seasoning matrix

A Dutch oven's cast iron seasoning matrix creates a durable, non-stick barrier that enhances flavor absorption and moisture retention during curing, whereas a raw steel skillet lacks this seasoned coating, making it more prone to rust and less effective at maintaining consistent curing conditions. The porous seasoning layer in cast iron traps oils and seasoning compounds, facilitating better flavor development and an even curing process compared to the bare surface of raw steel.

Dutch oven thermal inertia

A Dutch oven offers superior thermal inertia compared to a raw steel skillet, maintaining consistent heat levels crucial for precise curing processes. This steady temperature control minimizes fluctuations that can adversely affect the texture and flavor development during curing.

Raw steel patina buildup

Raw steel skillets develop a natural patina through repeated curing and seasoning, enhancing their non-stick properties and corrosion resistance over time. Unlike Dutch ovens, which rely on enamel coatings, raw steel's patina buildup forms a durable, chemical-free barrier that improves flavor retention and cooking performance with continuous use.

Uncoated skillet microtexturing

Uncoated raw steel skillets, including Dutch ovens, develop a natural microtextured seasoning layer during curing, enhancing non-stick properties and corrosion resistance without synthetic coatings. This microtexturing improves heat retention and distribution, making raw steel skillets ideal for controlled curing processes compared to coated alternatives.

Protein adhesion resistance

Dutch ovens, made from enameled cast iron, offer superior protein adhesion resistance during curing due to their smooth, non-porous surface that prevents proteins from bonding. Raw steel skillets, though durable, tend to develop microscopic porous layers that increase protein adhesion, making cleaning and curing less efficient.

Oil smoke point alignment

Dutch ovens and raw steel skillets differ significantly in oil smoke point alignment during curing; Dutch ovens generally retain heat evenly, minimizing localized overheating and maintaining optimal oil temperatures below smoke points. Raw steel skillets, with less heat distribution control, risk surpassing oil smoke points more easily, potentially compromising seasoning layers and flavor development.

Triple-layer seasoning method

The triple-layer seasoning method enhances both Dutch ovens and raw steel skillets by building durable, non-stick surfaces that improve curing performance; Dutch ovens offer even heat distribution and moisture retention, while raw steel skillets provide higher heat responsiveness and lighter weight for quicker seasoning absorption. Optimal curing results depend on applying multiple seasoning layers with polymerized oils to create a resilient patina that resists rust and promotes flavorful food.

Iron oxide stabilization

Dutch ovens provide a more controlled environment for curing due to their thick iron walls, which promote uniform iron oxide stabilization and reduce oxidation variability. In contrast, raw steel skillets, lacking the insulated design, tend to experience uneven iron oxide formation, potentially compromising the curing process and final product quality.

Dutch oven vs raw steel skillet for curing. Infographic

cookingdiff.com

cookingdiff.com