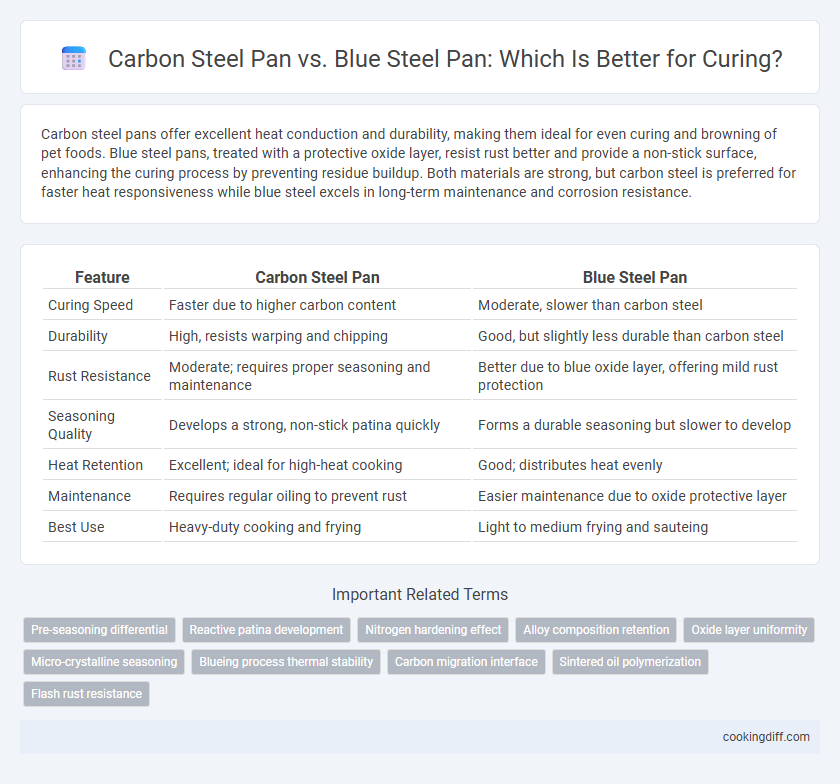

Carbon steel pans offer excellent heat conduction and durability, making them ideal for even curing and browning of pet foods. Blue steel pans, treated with a protective oxide layer, resist rust better and provide a non-stick surface, enhancing the curing process by preventing residue buildup. Both materials are strong, but carbon steel is preferred for faster heat responsiveness while blue steel excels in long-term maintenance and corrosion resistance.

Table of Comparison

| Feature | Carbon Steel Pan | Blue Steel Pan |

|---|---|---|

| Curing Speed | Faster due to higher carbon content | Moderate, slower than carbon steel |

| Durability | High, resists warping and chipping | Good, but slightly less durable than carbon steel |

| Rust Resistance | Moderate; requires proper seasoning and maintenance | Better due to blue oxide layer, offering mild rust protection |

| Seasoning Quality | Develops a strong, non-stick patina quickly | Forms a durable seasoning but slower to develop |

| Heat Retention | Excellent; ideal for high-heat cooking | Good; distributes heat evenly |

| Maintenance | Requires regular oiling to prevent rust | Easier maintenance due to oxide protective layer |

| Best Use | Heavy-duty cooking and frying | Light to medium frying and sauteing |

Introduction to Curing: Why It Matters in Cooking

Curing is essential in cooking to create a natural non-stick surface and prevent rust on pans, enhancing their longevity and performance. Both carbon steel and blue steel pans require proper curing to optimize heat distribution and develop a protective seasoning layer.

- Carbon Steel Pan - Known for its excellent heat retention and durability, making it ideal for high-heat cooking and curing processes.

- Blue Steel Pan - Features a unique oxide layer that provides initial rust resistance but still benefits from curing to improve seasoning adherence.

- Importance of Curing - Curing improves flavor development, prevents food from sticking, and protects the pan from corrosion over time.

Mastering the curing process is vital for maximizing the cooking performance and lifespan of both carbon steel and blue steel pans.

What Is a Carbon Steel Pan?

A carbon steel pan is crafted from an alloy of iron and carbon, offering excellent heat conductivity and durability. It is favored for its ability to develop a natural non-stick patina through seasoning, much like cast iron.

The pan's surface is initially reactive and requires proper curing to prevent rust and enhance cooking performance. Carbon steel pans heat quickly and evenly, making them ideal for searing and frying. Compared to blue steel pans, carbon steel typically has a slightly higher carbon content, resulting in greater hardness and improved longevity with continued use.

What Is a Blue Steel Pan?

A blue steel pan is crafted from low carbon steel that undergoes a heat treatment process, creating a durable bluish layer resistant to rust. Unlike carbon steel pans, blue steel pans offer a smoother surface that improves with seasoning and provides excellent heat retention for even cooking. This makes blue steel pans ideal for curing applications where consistent temperature and a non-reactive surface are crucial.

Composition Differences: Carbon Steel vs Blue Steel

Carbon steel pans are composed primarily of iron and a higher percentage of carbon, typically around 0.5-1.0%, which enhances hardness and heat retention, making them ideal for curing processes requiring durable surfaces. Blue steel pans, a subset of carbon steel with an added tempering process, develop a thin oxide layer that provides slight corrosion resistance while maintaining similar carbon content for effective curing.

- Carbon Content - Carbon steel contains approximately 0.5-1.0% carbon, increasing its hardness and durability for curing applications.

- Surface Treatment - Blue steel undergoes a tempering process creating a blue oxide layer that enhances corrosion resistance during curing.

- Material Composition - Both pans are iron-based, but blue steel's additional tempering differentiates its performance under curing conditions.

Curing Process: Step-by-Step for Carbon Steel Pans

The curing process for carbon steel pans begins with washing the pan thoroughly to remove manufacturing residues, followed by drying it completely. Next, a thin layer of oil is applied to the entire surface to prevent rust and prepare the pan for seasoning.

Heating the pan on medium-high heat allows the oil to polymerize, creating a natural non-stick coating ideal for cooking. Repeating this heating and oiling cycle several times builds up a durable seasoning that enhances the pan's performance and longevity.

Curing Process: Step-by-Step for Blue Steel Pans

How does the curing process differ for blue steel pans compared to carbon steel pans? Blue steel pans require a thorough initial cleaning followed by a layer of oil applied before heating to develop a protective patina. This step-by-step curing enhances the pan's non-stick properties and prevents rust, making it essential for optimal performance.

Performance and Durability After Curing

Carbon steel pans exhibit excellent heat retention and distribute heat evenly, making them ideal for curing processes requiring precise temperature control. Blue steel pans, treated with a protective oxide layer, offer enhanced corrosion resistance, improving durability during prolonged curing cycles involving moisture exposure. Both materials maintain structural integrity well, but blue steel's finish reduces the risk of rust, extending the lifespan after repeated curing applications.

Flavor Impact: Do Steel Types Affect Taste?

Carbon steel pans develop a natural non-stick patina through curing, which can slightly enhance the flavor of food by adding a subtle depth and complexity. Blue steel pans, with a higher heat tolerance and quicker responsiveness, may influence taste by providing more consistent cooking temperatures for flavor preservation.

- Carbon Steel Flavor Impact - The seasoning layer absorbs and releases flavors over time, subtly improving taste.

- Blue Steel Heat Conductivity - Superior heat retention aids in even cooking, reducing flavor loss from temperature fluctuations.

- Material Reactivity - Both steels interact minimally with acidic foods, preserving natural flavors without metallic taint.

Maintenance and Longevity of Cured Pans

Carbon steel pans require regular seasoning and careful drying to prevent rust, promoting durability through consistent maintenance. Blue steel pans develop a natural patina that enhances their non-stick properties and resistance to corrosion over time with minimal upkeep.

Proper storage in a dry environment extends the lifespan of both carbon and blue steel pans, though blue steel's oxide layer offers extra protection against moisture. Frequent reseasoning of carbon steel pans can restore their protective layer, ensuring long-lasting performance and longevity.

Related Important Terms

Pre-seasoning differential

Carbon steel pans require thorough pre-seasoning to build a durable, non-stick patina due to their higher carbon content, which promotes faster rusting if unprotected. Blue steel pans, with a thin oxidized layer from heat treatment, need less intensive pre-seasoning and offer better initial rust resistance, providing a more straightforward curing process for everyday use.

Reactive patina development

Carbon steel pans develop a reactive patina more quickly than blue steel pans due to their higher carbon content, which promotes faster oxidation and seasoning. Blue steel pans, treated with a heat oxidation layer, resist rust longer but form a more stable, less reactive patina ideal for controlled curing environments.

Nitrogen hardening effect

Nitrogen hardening enhances the surface hardness and wear resistance in blue steel pans more effectively than carbon steel pans due to the higher nitrogen absorption capacity of blue steel. This process results in a more durable and corrosion-resistant cured surface, making blue steel preferable for applications requiring superior hardness and longevity.

Alloy composition retention

Carbon steel pans retain their alloy composition effectively during curing, as their higher carbon content enhances durability and resistance to rust formation. Blue steel pans, treated with a heat-induced oxide layer, maintain alloy integrity by providing superior corrosion resistance, preserving the pan's surface and ensuring consistent curing performance over time.

Oxide layer uniformity

Blue steel pans develop a more uniform oxide layer during curing, enhancing non-stick properties and corrosion resistance, whereas carbon steel pans often exhibit uneven oxide formation that can lead to inconsistent seasoning. The consistent oxide film on blue steel improves durability and cooking performance by providing a stable, protective barrier.

Micro-crystalline seasoning

Carbon steel pans develop a durable micro-crystalline seasoning that enhances non-stick properties and resists rust through repeated heating and oil polymerization. Blue steel pans, while similar in composition, often require more attentive curing to build a consistent micro-crystalline layer due to their thinner oxide coating, which influences seasoning adherence and longevity.

Blueing process thermal stability

Blue steel pans, created through a controlled blueing process that forms a thin oxide layer, offer superior thermal stability during curing compared to carbon steel pans, which are more prone to uneven heat distribution and warping. The blueing oxide layer on blue steel enhances resistance to high temperatures, reduces oxidation, and improves durability, making it ideal for consistent and prolonged curing cycles.

Carbon migration interface

Carbon steel pans exhibit a more controlled carbon migration interface during curing, resulting in enhanced surface hardness and improved seasoning durability compared to blue steel pans. The blue steel pan's less stable carbon diffusion layer can lead to uneven curing, affecting long-term pan performance and corrosion resistance.

Sintered oil polymerization

Carbon steel pans develop a durable, non-stick surface through sintered oil polymerization, where heated oil molecules bond to the metal, creating a resilient seasoning layer. Blue steel pans, characterized by their oxide coating, require careful seasoning to achieve effective sintered oil polymerization for optimal curing and anti-corrosion performance.

Carbon steel pan vs Blue steel pan for curing. Infographic

cookingdiff.com

cookingdiff.com