The Bake-in Oven Method for utensil seasoning involves applying oil to the tool and heating it in a conventional oven at high temperatures, creating a durable, non-stick surface through polymerization. Sous Vide Oil Curing, by contrast, uses precise low-temperature water bath control to infuse oil deeply into the utensil's pores, resulting in a more even, long-lasting seasoning layer that enhances rust resistance and cooking performance. While the oven method is faster and accessible, sous vide curing offers superior control over seasoning uniformity and penetration, making it ideal for maintaining premium kitchen tools.

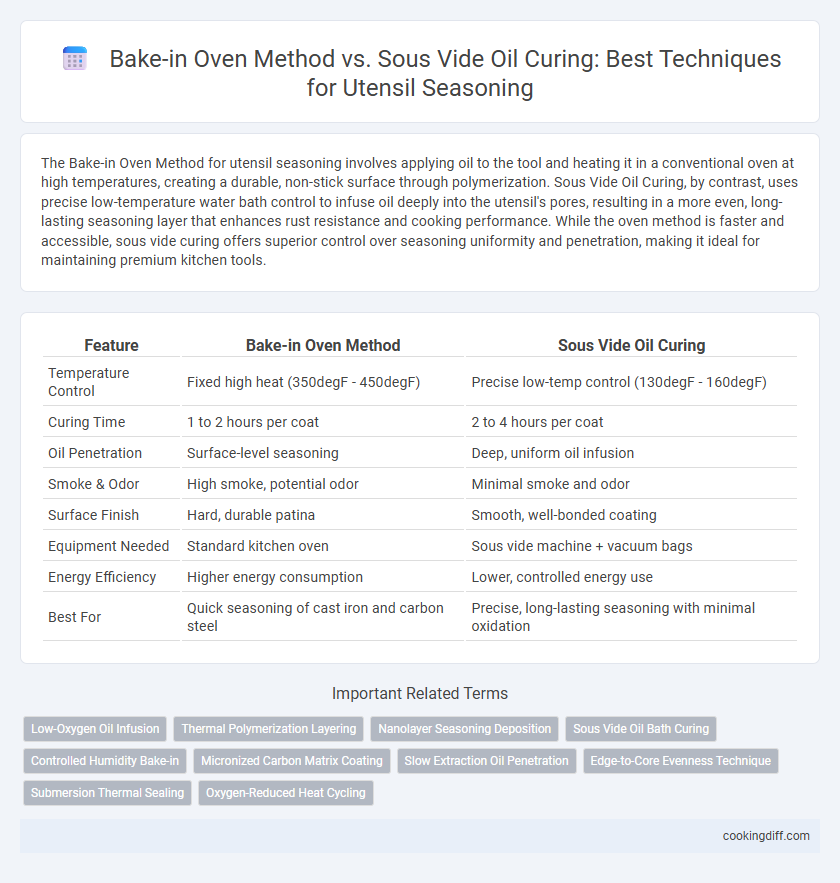

Table of Comparison

| Feature | Bake-in Oven Method | Sous Vide Oil Curing |

|---|---|---|

| Temperature Control | Fixed high heat (350degF - 450degF) | Precise low-temp control (130degF - 160degF) |

| Curing Time | 1 to 2 hours per coat | 2 to 4 hours per coat |

| Oil Penetration | Surface-level seasoning | Deep, uniform oil infusion |

| Smoke & Odor | High smoke, potential odor | Minimal smoke and odor |

| Surface Finish | Hard, durable patina | Smooth, well-bonded coating |

| Equipment Needed | Standard kitchen oven | Sous vide machine + vacuum bags |

| Energy Efficiency | Higher energy consumption | Lower, controlled energy use |

| Best For | Quick seasoning of cast iron and carbon steel | Precise, long-lasting seasoning with minimal oxidation |

Introduction to Bake-in Oven and Sous Vide Oil Curing Methods

The Bake-in Oven Method involves seasoning utensils by applying oil and heating them in a controlled oven environment, which promotes even oil polymerization and creates a durable, non-stick surface. Sous Vide Oil Curing uses precise temperature control in a water bath to infuse oil deeply into the utensil's surface, resulting in enhanced seasoning uniformity and durability. Both methods optimize seasoning but differ in temperature control, curing time, and the resulting finish quality.

Understanding Utensil Seasoning: Why It Matters

| Bake-in Oven Method | Utilizes consistent dry heat at around 350degF (175degC) to polymerize oil on metal utensils, creating a durable, non-stick seasoning layer essential for corrosion resistance and enhanced cooking performance. |

| Sous Vide Oil Curing | Employs precise temperature control, typically between 130degF and 160degF (54degC to 71degC), to gently infuse oil molecules into the utensil surface, producing a uniform seasoning that preserves utensil integrity and extends lifespan. |

| Importance of Utensil Seasoning | Seasoning prevents rust, improves non-stick properties, and enhances flavor compatibility, making it a critical maintenance step for cast iron and carbon steel utensils to ensure optimal kitchen efficiency and durability. |

How the Bake-in Oven Method Works

The Bake-in Oven Method uses consistent dry heat to polymerize the oil, creating a durable non-stick seasoning layer on utensils. This process involves heating utensils at temperatures typically between 350degF to 450degF for one to two hours, ensuring deep oil bonding.

- Controlled Heat Application - The oven provides stable, uniform heat that facilitates even curing of the oil coating.

- Oxidation and Polymerization - The heat initiates chemical reactions, transforming oil molecules into a hard, protective seasoning layer.

- Time Efficiency - Extended oven heating produces a robust seasoning that enhances the utensil's longevity and performance.

Exploring Sous Vide Oil Curing for Utensils

Sous vide oil curing for utensils offers precise temperature control that enhances the polymerization of seasoning oils, resulting in a durable, non-stick surface. This method reduces the risk of overheating compared to traditional bake-in oven techniques, preserving the integrity of the utensil's metal.

- Consistent Heat Distribution - Sous vide maintains uniform temperatures around utensils, ensuring even seasoning without hot spots.

- Enhanced Oil Penetration - The controlled environment allows oils to penetrate deeper into the metal's pores, strengthening the seasoning layer.

- Reduced Oxidation Risks - Lower temperatures prevent oil breakdown and excessive smoke, extending the longevity of the seasoning.

Key Differences Between Bake-in Oven and Sous Vide Oil Curing

What are the key differences between Bake-in Oven and Sous Vide Oil Curing methods for utensil seasoning? Bake-in Oven curing uses high, dry heat to polymerize oil directly on the utensil surface, creating a hard, durable coating. Sous Vide Oil Curing involves low-temperature water bath heating for precise temperature control, resulting in a more uniform and deeply penetrated seasoning layer.

Temperature Control and Oil Polymerization Efficiency

Bake-in oven method offers consistent high-temperature control, typically between 350degF to 450degF, promoting rapid oil polymerization and forming a durable seasoning layer on utensils. Maintaining precise oven temperature enhances uniform curing and reduces the risk of uneven seasoning or sticky residue.

Sous vide oil curing operates at lower temperatures, around 130degF to 185degF, enabling slow and controlled polymerization of oils, which minimizes the risk of overheating and oil degradation. This method provides superior temperature stability, resulting in a more even and long-lasting seasoning layer on delicate utensils.

Flavor and Coating Quality: Results Comparison

Bake-in oven curing produces a robust, slightly smoky flavor and a thicker, more durable coating, while sous vide oil curing yields a subtle, evenly infused taste with a smoother, more uniform layer. Flavor intensity and coating consistency vary significantly between these two methods, impacting utensil performance and longevity.

- Bake-in oven method enhances seasoning durability - The high heat allows polymerization, creating a hard, protective coating.

- Sous vide oil curing offers precise flavor infusion - Low temperature immersion enables oil absorption without burning.

- Bake-in method results in a more pronounced, smoky aroma - Heat exposure triggers Maillard reactions enhancing flavor complexity.

Sous vide oil curing provides more control over flavor and a gentler coating, ideal for delicate seasoning profiles.

Time, Convenience, and Equipment Needed

The Bake-in Oven Method requires longer curing times, typically 1-2 hours, but uses common kitchen equipment like a conventional oven, making it convenient for most home cooks. Sous Vide Oil Curing offers precise temperature control and faster curing, usually around 1 hour, but demands specialized sous vide equipment and vacuum-sealed bags. Considering time efficiency, convenience, and equipment, oven curing suits casual users while sous vide appeals to those prioritizing precision and consistency.

Suitability for Different Utensil Materials

Bake-in oven method suits cast iron and carbon steel utensils, providing even heat distribution that enhances seasoning durability. This method is ideal for utensils that can withstand prolonged exposure to high temperatures without warping or damage.

Sous vide oil curing is better suited for delicate materials like stainless steel and aluminum, as it offers precise temperature control to prevent overheating. It allows consistent seasoning without compromising the structural integrity of sensitive utensils.

Related Important Terms

Low-Oxygen Oil Infusion

Low-oxygen oil infusion in bake-in oven curing promotes deeper penetration of seasoning oils into utensil surfaces by minimizing oxidation, enhancing durability and non-stick properties. Sous vide oil curing precisely controls temperature and oxygen exposure, yielding uniform seasoning layers with reduced risk of oil polymerization and uneven coatings.

Thermal Polymerization Layering

Bake-in oven method creates a robust thermal polymerization layer by exposing utensils to consistent high heat, resulting in durable seasoning with enhanced adhesion and heat resistance. Sous vide oil curing offers precise temperature control, promoting uniform polymerization and reducing the risk of burning, which yields a finely layered, non-stick surface ideal for delicate cookware.

Nanolayer Seasoning Deposition

Nanolayer seasoning deposition enhances utensil durability and non-stick properties by creating uniform, molecularly bonded layers during the Bake-in Oven Method, which ensures consistent heat application for optimal polymerization. Sous Vide Oil Curing, while precise in temperature control, may produce less uniform nanolayer formation due to lower temperature gradients, impacting long-term seasoning adhesion and performance.

Sous Vide Oil Bath Curing

Sous vide oil bath curing immerses utensils in precisely controlled temperature oil, ensuring uniform seasoning and deeper oil polymerization compared to bake-in oven methods. This technique enhances non-stick properties and corrosion resistance by maintaining consistent heat around 135-160degC for extended periods, optimizing the curing process at the molecular level.

Controlled Humidity Bake-in

Controlled humidity bake-in ovens ensure precise moisture levels during utensil seasoning, promoting uniform oil polymerization and preventing oxidation. This method contrasts with sous vide oil curing by offering enhanced temperature stability and moisture control, resulting in a more durable and evenly seasoned surface.

Micronized Carbon Matrix Coating

The Bake-in Oven Method utilizes high temperatures to bond the Micronized Carbon Matrix Coating onto utensils, creating a durable, heat-resistant surface ideal for long-term seasoning. Sous Vide Oil Curing, by contrast, allows precise temperature control to infuse oils into the Micronized Carbon Matrix, enhancing non-stick properties without compromising the coating's structural integrity.

Slow Extraction Oil Penetration

Bake-in oven seasoning promotes slow extraction oil penetration by maintaining a consistent temperature, allowing oils to polymerize and bond evenly within the utensil's surface pores. Sous vide oil curing achieves precise temperature control to optimize the slow infusion of oil into utensils, enhancing durability and corrosion resistance through gradual molecular absorption.

Edge-to-Core Evenness Technique

The Bake-in Oven Method ensures uniform heat distribution by maintaining a consistent high temperature, promoting even seasoning from edge to core in metal utensils. Sous Vide Oil Curing offers precise temperature control in a liquid medium, allowing oil penetration and seasoning uniformity while minimizing thermal gradients that cause uneven curing.

Submersion Thermal Sealing

The bake-in oven method relies on dry heat to polymerize oil on utensil surfaces, forming a hard, durable seasoning layer through oxidative bonding, while sous vide oil curing employs precise temperature control and full oil submersion to achieve uniform thermal sealing without oxidation. Submersion thermal sealing in sous vide ensures even oil penetration and consistent seasoning thickness, reducing the risk of uneven curing or burnt layers common in oven baking.

Bake-in Oven Method vs Sous Vide Oil Curing for utensil seasoning. Infographic

cookingdiff.com

cookingdiff.com