Glass jars provide a simple and affordable option for curing pets, maintaining a stable environment with minimal equipment. Vacuum fermenters offer precise control over air pressure and humidity, accelerating the curing process and enhancing flavor development. Choosing between the two depends on budget and desired curing efficiency.

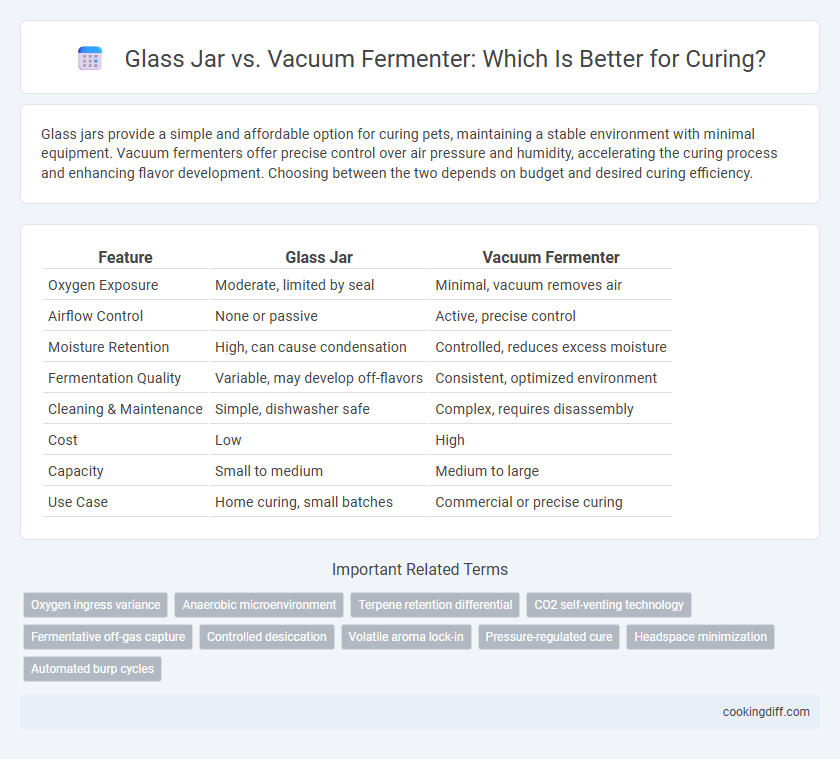

Table of Comparison

| Feature | Glass Jar | Vacuum Fermenter |

|---|---|---|

| Oxygen Exposure | Moderate, limited by seal | Minimal, vacuum removes air |

| Airflow Control | None or passive | Active, precise control |

| Moisture Retention | High, can cause condensation | Controlled, reduces excess moisture |

| Fermentation Quality | Variable, may develop off-flavors | Consistent, optimized environment |

| Cleaning & Maintenance | Simple, dishwasher safe | Complex, requires disassembly |

| Cost | Low | High |

| Capacity | Small to medium | Medium to large |

| Use Case | Home curing, small batches | Commercial or precise curing |

Introduction to Curing: Glass Jars vs Vacuum Fermenters

Curing is essential for enhancing flavors and preserving the quality of various foods through controlled aging processes. Glass jars and vacuum fermenters represent two distinct methods, each offering unique benefits based on the level of oxygen exposure and environmental control.

- Glass Jars Retain Oxygen - Glass jars allow a small amount of oxygen exchange, which can enhance aerobic fermentation and complex flavor profiles.

- Vacuum Fermenters Remove Air - Vacuum fermenters create a low-oxygen environment that slows oxidation and promotes anaerobic fermentation, preserving freshness longer.

- Control and Consistency - Vacuum fermenters provide precise control over pressure and atmosphere, leading to more consistent curing results compared to traditional glass jars.

How Glass Jars Work in the Curing Process

Glass jars provide an airtight environment that helps regulate humidity and prevent contamination during the curing process. Their non-reactive surface preserves the taste and aroma without imparting any unwanted flavors.

- Airtight Seal - Creates a controlled atmosphere essential for maintaining optimal moisture levels.

- Non-reactive Material - Prevents chemical reactions that could affect the curing quality.

- Visibility - Allows easy monitoring of the curing progress without opening the container.

This precise environment makes glass jars a reliable choice for consistent and high-quality curing results.

Benefits of Using Vacuum Fermenters for Curing

Vacuum fermenters create a controlled, oxygen-free environment that significantly reduces oxidation, preserving the flavor and quality of the product during curing. This method also accelerates the curing process by evenly distributing pressure and temperature, enhancing consistency and efficiency.

Unlike glass jars, vacuum fermenters minimize contamination risks by maintaining a sealed atmosphere, ensuring a more hygienic curing environment. The precise control over environmental factors in vacuum fermenters leads to better product texture and extended shelf life.

Oxygen Control: Glass Jar vs Vacuum Fermenter

How does oxygen control differ between a glass jar and a vacuum fermenter for curing? Glass jars allow minimal airflow, which can lead to inconsistent oxygen levels during the curing process. Vacuum fermenters actively remove oxygen, providing a controlled anaerobic environment that enhances preservation and prevents oxidation.

Flavor Development: Impact of Container Choice

| Glass jars provide an airtight seal that slows oxidation, preserving delicate flavor compounds during the curing process, which enhances the clarity and brightness of the final product's taste profile. |

| Vacuum fermenters reduce oxygen exposure even further by actively extracting air, accelerating enzymatic reactions and microbial activity that contribute to deeper, more complex flavor development in cured goods. |

| Choosing between glass jars and vacuum fermenters impacts the intensity and nuance of flavor; vacuum fermenters typically deliver bolder, richer tastes, while glass jars maintain a fresher, more subtle flavor balance throughout curing. |

Mold Prevention: Safety in Glass Jars and Vacuum Fermenters

Glass jars provide a breathable environment that can reduce moisture buildup, lowering the risk of mold during curing. Vacuum fermenters eliminate air exposure, creating an anaerobic setting that further prevents mold growth by restricting mold spores' access to oxygen.

- Glass Jars Promote Air Circulation - Slight airflow helps control humidity and inhibits mold development.

- Vacuum Fermenters Create Oxygen-Free Conditions - Removing air prevents mold spores from thriving in the curing environment.

- Both Methods Enhance Safety - Each offers a distinct approach to mold prevention, improving product quality and shelf life.

Ease of Use and Maintenance Comparison

Glass jars provide straightforward ease of use with simple sealing mechanisms, making them accessible for small-batch curing without specialized equipment. Vacuum fermenters offer more advanced control over the curing environment but require regular maintenance of vacuum pumps and seals to ensure optimal performance. Cleaning glass jars is typically easier and less time-consuming compared to the complex parts and filtration systems involved in vacuum fermenters.

Long-term Storage: Preservation Quality

Glass jars provide an airtight seal that effectively preserves flavor and aroma during long-term storage in curing processes. Their non-reactive surface prevents contamination, maintaining the quality of cured products over extended periods.

Vacuum fermenters optimize preservation by removing oxygen, which significantly slows down oxidation and microbial growth, ensuring longer shelf life. The controlled environment in vacuum fermenters enhances the consistency and safety of cured goods. Compared to glass jars, they offer superior protection against spoilage but require more maintenance and energy.

Cost and Accessibility: Which is More Practical?

Glass jars are more cost-effective and widely accessible for curing due to their low initial price and availability in most households. They do not require specialized equipment, making them practical for beginners and small-scale projects.

Vacuum fermenters involve a higher initial investment and may require specific maintenance, limiting their accessibility. However, they offer precise control over the curing environment, which can justify the cost for large-scale or professional use.

Related Important Terms

Oxygen ingress variance

Glass jars provide a reliable seal against oxygen ingress with minimal permeability, maintaining a stable anaerobic environment essential for effective curing. Vacuum fermenters reduce oxygen exposure even further by actively removing air, thereby preventing oxidative spoilage and enhancing flavor preservation during the curing process.

Anaerobic microenvironment

Glass jars provide a simple anaerobic microenvironment for curing by limiting oxygen exposure, but vacuum fermenters enhance this environment more effectively by actively removing air and creating a consistent low-oxygen atmosphere. The improved anaerobic conditions in vacuum fermenters accelerate fermentation, reduce spoilage risk, and maintain product quality during the curing process.

Terpene retention differential

Glass jars offer moderate terpene retention during curing due to limited air exchange and consistent humidity control, while vacuum fermenters excel by significantly reducing oxygen exposure and volatile terpene loss through airtight vacuum sealing, preserving a richer aromatic profile. Studies show vacuum fermenters can retain up to 30% more terpenes compared to traditional glass jars, making them a superior choice for terpene preservation in curing processes.

CO2 self-venting technology

Vacuum fermenters with CO2 self-venting technology offer precise gas regulation that prevents pressure build-up during curing, enhancing the preservation of flavor and aroma compared to traditional glass jars. This advanced system automatically releases excess CO2 while maintaining an anaerobic environment, reducing the risk of oxidation and microbial contamination.

Fermentative off-gas capture

Vacuum fermenters efficiently capture fermentative off-gas by maintaining a controlled low-pressure environment that prevents gas escape, unlike glass jars which allow off-gas buildup and risk jar sealing failure. This precise gas control enhances curing consistency by minimizing oxidation and contamination during fermentation.

Controlled desiccation

Glass jars provide a simple, airtight environment that supports controlled desiccation by limiting moisture exchange, but vacuum fermenters enhance this process through precise pressure regulation and consistent humidity control, accelerating drying and preserving quality. Vacuum fermenters reduce oxidation and microbial growth more effectively than glass jars, ensuring a more uniform and reliable curing outcome.

Volatile aroma lock-in

Vacuum fermenters enhance volatile aroma lock-in by removing oxygen and reducing oxidation, which preserves delicate fragrance compounds more effectively than glass jars. Glass jars, while airtight, can still allow minimal gas exchange that may lead to slight aroma degradation during curing.

Pressure-regulated cure

Pressure-regulated curing in a vacuum fermenter ensures consistent atmospheric control, enhancing fermentation quality by minimizing oxidation and contamination compared to the less controlled environment of glass jars. Vacuum fermenters maintain precise pressure levels, optimizing microbial activity and flavor development during the curing process.

Headspace minimization

Vacuum fermenters significantly reduce headspace during the curing process, minimizing oxygen exposure and enhancing preservation compared to traditional glass jars. This reduction in headspace prevents oxidation and slows microbial growth, ensuring optimal flavor retention and extended shelf life.

Glass jar vs vacuum fermenter for curing. Infographic

cookingdiff.com

cookingdiff.com