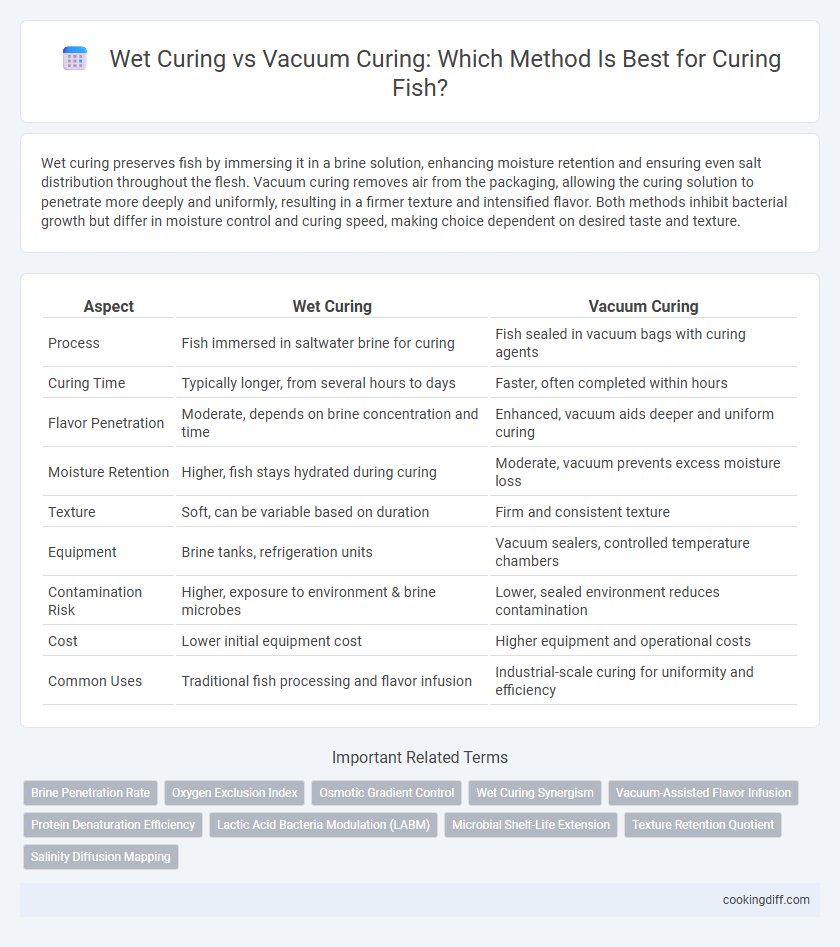

Wet curing preserves fish by immersing it in a brine solution, enhancing moisture retention and ensuring even salt distribution throughout the flesh. Vacuum curing removes air from the packaging, allowing the curing solution to penetrate more deeply and uniformly, resulting in a firmer texture and intensified flavor. Both methods inhibit bacterial growth but differ in moisture control and curing speed, making choice dependent on desired taste and texture.

Table of Comparison

| Aspect | Wet Curing | Vacuum Curing |

|---|---|---|

| Process | Fish immersed in saltwater brine for curing | Fish sealed in vacuum bags with curing agents |

| Curing Time | Typically longer, from several hours to days | Faster, often completed within hours |

| Flavor Penetration | Moderate, depends on brine concentration and time | Enhanced, vacuum aids deeper and uniform curing |

| Moisture Retention | Higher, fish stays hydrated during curing | Moderate, vacuum prevents excess moisture loss |

| Texture | Soft, can be variable based on duration | Firm and consistent texture |

| Equipment | Brine tanks, refrigeration units | Vacuum sealers, controlled temperature chambers |

| Contamination Risk | Higher, exposure to environment & brine microbes | Lower, sealed environment reduces contamination |

| Cost | Lower initial equipment cost | Higher equipment and operational costs |

| Common Uses | Traditional fish processing and flavor infusion | Industrial-scale curing for uniformity and efficiency |

Introduction to Fish Curing Methods

Fish curing is an essential preservation method that extends shelf life and enhances flavor by controlling microbial growth and enzymatic activity. Wet curing and vacuum curing represent two distinct techniques with unique benefits and applications in the seafood industry.

- Wet curing - involves immersing fish in a brine solution to evenly distribute salt and other curing agents, improving moisture retention and flavor penetration.

- Vacuum curing - utilizes a vacuum chamber to infuse curing agents rapidly, ensuring deep and uniform absorption while reducing curing time.

- Comparison focus - choosing between wet and vacuum curing depends on factors such as desired texture, processing speed, and product shelf life requirements.

What is Wet Curing for Fish?

| Wet curing for fish involves immersing the fish in a brine solution composed primarily of water, salt, and sometimes sugar or other flavoring agents to enhance preservation and taste. |

| This method promotes moisture retention, helps control microbial growth, and improves texture by allowing the brine to penetrate the flesh uniformly. |

| Wet curing is favored for larger fish species and products requiring a tender, moist finish, differing from vacuum curing, which relies on pressure and vacuum sealing to infuse curing agents. |

What is Vacuum Curing for Fish?

Vacuum curing for fish involves placing the fish in a vacuum-sealed environment to enhance flavor absorption and reduce curing time. This method removes air from the packaging, allowing the curing solution to penetrate more evenly and deeply into the fish tissue. Vacuum curing maintains freshness and improves texture, making it a preferred choice in industrial and artisanal fish processing.

Key Differences Between Wet and Vacuum Curing

Wet curing involves submerging fish in a brine solution to enhance moisture retention and flavor absorption, while vacuum curing uses a sealed environment to infuse curing agents evenly without added liquid. The choice between these methods impacts texture, curing time, and flavor intensity in the final product.

- Moisture Retention - Wet curing preserves higher moisture levels, resulting in a juicier texture.

- Curing Speed - Vacuum curing accelerates the process by enhancing diffusion of curing agents through pressure.

- Flavor Penetration - Wet curing offers a more uniform flavor due to immersion in brine.

Understanding these differences helps optimize curing techniques for desired fish quality and shelf life.

Flavor Profiles: Wet Curing vs Vacuum Curing

How do flavor profiles differ between wet curing and vacuum curing for fish? Wet curing infuses fish with a saltwater brine, enhancing moisture retention and delivering a traditional, mildly salty taste. Vacuum curing intensifies flavor absorption by removing air, resulting in a firmer texture and a more concentrated, savory profile.

Texture and Moisture Retention in Fish

Wet curing enhances fish texture by allowing gradual absorption of brine, which maintains a moist and tender flesh. Vacuum curing accelerates moisture retention through direct brine contact under reduced pressure, resulting in a firmer texture and more uniform salt penetration. Compared to wet curing, vacuum curing provides a consistent and controlled environment that improves overall moisture distribution and texture stability in fish products.

Time Efficiency: Which Method is Faster?

Wet curing typically requires a longer processing time, often ranging from several hours to days, due to the slow absorption of brine into the fish. In contrast, vacuum curing accelerates this process by creating a low-pressure environment that enhances brine penetration, significantly reducing curing time.

Vacuum curing can decrease curing duration by up to 50% compared to traditional wet curing, making it the more time-efficient option for commercial fish processing. This efficiency enables faster turnover and improved productivity without compromising flavor or texture.

Equipment and Preparation Process

Wet curing requires large, food-grade tanks equipped with temperature control and circulation systems to ensure even brine distribution. Vacuum curing utilizes vacuum tumblers or chambers that apply pressure to speed absorption and enhance flavor penetration.

Preparation for wet curing involves mixing precise saline solutions and maintaining consistent cold temperatures to prevent spoilage. Vacuum curing preparation includes placing the fish in sealed bags before vacuum sealing to remove air and promote marinade infusion. Both methods demand meticulous sanitation of equipment to preserve product quality and safety.

Food Safety Considerations in Curing Fish

Wet curing fish involves immersing the product in a brine solution, which inhibits microbial growth by reducing water activity and maintaining salt concentration. This method requires strict control of temperature and brine composition to prevent pathogenic bacteria such as Listeria monocytogenes and Clostridium botulinum from proliferating.

Vacuum curing creates an anaerobic environment by removing air and tightly sealing the fish in vacuum packages, significantly reducing oxidation and microbial contamination risks. Proper vacuum sealing combined with refrigeration enhances food safety by limiting spoilage organisms and preserving the fish's quality during storage.

Related Important Terms

Brine Penetration Rate

Wet curing achieves a higher brine penetration rate due to the direct contact between fish and the saline solution, enhancing flavor absorption and moisture retention. Vacuum curing accelerates brine diffusion by removing air pockets, resulting in more uniform and faster penetration of curing agents into the fish tissue.

Oxygen Exclusion Index

Wet curing preserves fish by immersing it in brine, which allows limited oxygen exposure, resulting in a moderate Oxygen Exclusion Index that slows oxidation but does not eliminate it entirely. Vacuum curing removes nearly all oxygen by sealing fish in an airtight environment, achieving a high Oxygen Exclusion Index that significantly enhances shelf life and flavor stability.

Osmotic Gradient Control

Wet curing relies on maintaining a precise salt concentration in the brine to establish an optimal osmotic gradient, facilitating uniform salt penetration and moisture regulation in fish. Vacuum curing enhances osmotic gradient control by removing air from the curing environment, accelerating salt diffusion and improving texture and flavor consistency.

Wet Curing Synergism

Wet curing enhances flavor absorption and moisture retention in fish by allowing salt and curing agents to penetrate evenly, creating a synergistic effect with natural enzymes that improve texture and preservation. This method contrasts with vacuum curing, where rapid dehydration can limit enzyme activity and flavor development, making wet curing ideal for achieving a balanced, succulent final product.

Vacuum-Assisted Flavor Infusion

Vacuum curing enhances flavor infusion in fish by using reduced pressure to accelerate brine absorption, resulting in uniform seasoning and improved texture. This method outperforms traditional wet curing by minimizing processing time while preserving moisture and maximizing taste penetration.

Protein Denaturation Efficiency

Wet curing facilitates uniform protein denaturation in fish by allowing salt and moisture to penetrate muscle tissues, enhancing texture and flavor development. Vacuum curing accelerates protein denaturation efficiency by creating a low-pressure environment that promotes deeper and faster diffusion of curing agents into fish muscles, resulting in improved preservation and tenderness.

Lactic Acid Bacteria Modulation (LABM)

Wet curing enhances Lactic Acid Bacteria Modulation (LABM) by providing a moist environment that promotes the growth of beneficial LAB strains, improving fish texture and flavor through controlled fermentation. Vacuum curing restricts oxygen, selectively stimulating anaerobic LAB activity which intensifies preservation effects and develops unique taste profiles in cured fish.

Microbial Shelf-Life Extension

Wet curing preserves fish by immersing it in brine, enhancing microbial shelf-life extension through salt's inhibitory effects on spoilage bacteria. Vacuum curing removes air, creating an anaerobic environment that slows microbial growth and prolongs fish freshness more effectively than wet curing.

Texture Retention Quotient

Wet curing preserves fish's moisture content more effectively, resulting in a higher Texture Retention Quotient (TRQ) by maintaining firmness and juiciness throughout the process. Vacuum curing minimizes oxidation and microbial growth, enhancing texture stability but often yields a slightly lower TRQ compared to wet curing due to reduced moisture retention.

Wet Curing vs Vacuum Curing for fish. Infographic

cookingdiff.com

cookingdiff.com