Curing a carbon steel wok involves heating and oiling it to create a natural non-stick layer and prevent rust, which enhances its cooking performance and longevity. Passivation, on the other hand, refers to treating the steel to form a protective oxide layer primarily for corrosion resistance but does not produce a non-stick surface. For carbon steel woks, curing is essential to develop seasoning that improves flavor and durability, while passivation alone is insufficient for cooking purposes.

Table of Comparison

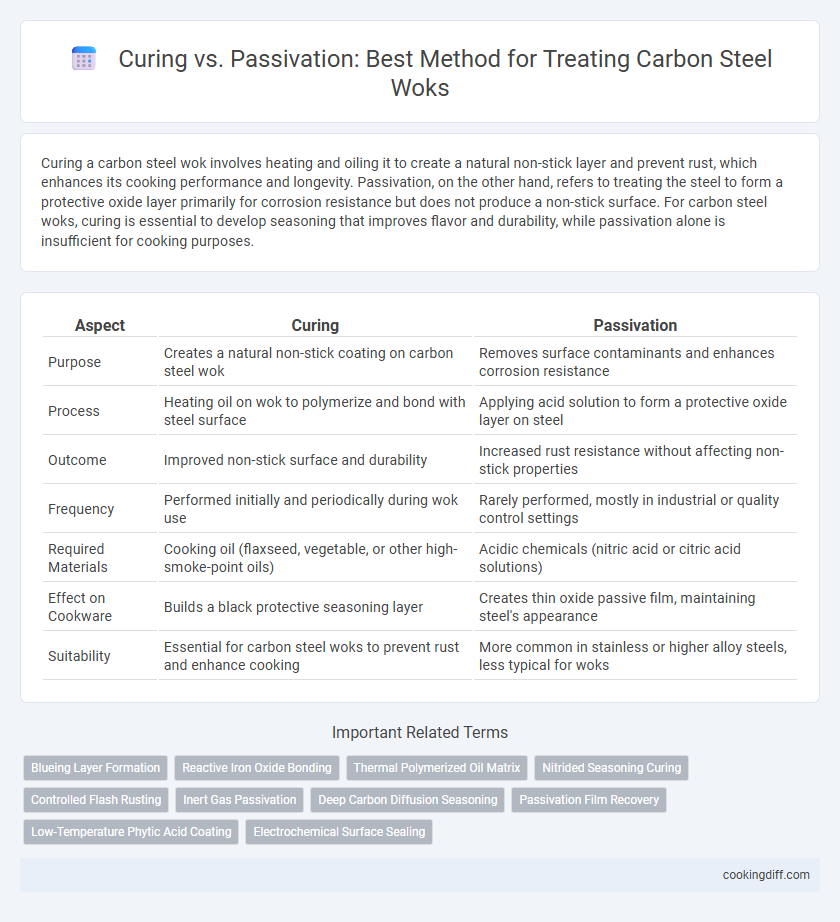

| Aspect | Curing | Passivation |

|---|---|---|

| Purpose | Creates a natural non-stick coating on carbon steel wok | Removes surface contaminants and enhances corrosion resistance |

| Process | Heating oil on wok to polymerize and bond with steel surface | Applying acid solution to form a protective oxide layer on steel |

| Outcome | Improved non-stick surface and durability | Increased rust resistance without affecting non-stick properties |

| Frequency | Performed initially and periodically during wok use | Rarely performed, mostly in industrial or quality control settings |

| Required Materials | Cooking oil (flaxseed, vegetable, or other high-smoke-point oils) | Acidic chemicals (nitric acid or citric acid solutions) |

| Effect on Cookware | Builds a black protective seasoning layer | Creates thin oxide passive film, maintaining steel's appearance |

| Suitability | Essential for carbon steel woks to prevent rust and enhance cooking | More common in stainless or higher alloy steels, less typical for woks |

Understanding Curing and Passivation for Carbon Steel Woks

Curing a carbon steel wok involves coating it with oil and heating it to create a durable, non-stick layer that protects against rust and enhances cooking performance. This process polymerizes the oil, forming a natural, food-safe seasoning that improves with use.

Passivation, on the other hand, is a chemical treatment that removes free iron from the metal surface, forming a thin oxide layer to prevent corrosion but does not create a non-stick surface. Understanding these differences helps maintain carbon steel woks effectively for longevity and optimal cooking results.

What Is Curing in the Context of Carbon Steel Woks?

What is curing in the context of carbon steel woks? Curing a carbon steel wok involves heating the pan to create a durable, non-stick layer by polymerizing oils absorbed into the metal's surface. This process enhances the wok's resistance to rust and improves cooking performance by developing a natural seasoning layer.

Passivation Explained: Protecting Carbon Steel Wok Surfaces

Passivation is a chemical process that enhances the corrosion resistance of carbon steel woks by forming a protective oxide layer on the surface. Unlike curing, which develops a seasoning layer for non-stick properties, passivation focuses on preventing rust and maintaining the wok's structural integrity.

- Oxide Layer Formation - Passivation creates a thin, inert oxide film that shields the metal from environmental exposure.

- Corrosion Prevention - This process significantly reduces the risk of rust and surface degradation over time.

- Surface Stability - Passivated carbon steel woks maintain their strength and durability without altering cooking performance.

Key Differences: Curing vs Passivation for Wok Maintenance

Curing a carbon steel wok involves heating oil to polymerize and create a non-stick, rust-resistant layer, while passivation treats the steel surface to form a protective oxide layer that reduces corrosion. Curing improves cooking performance by developing seasoning, whereas passivation primarily enhances rust resistance without affecting non-stick properties.

During curing, oils like flaxseed or vegetable oil are applied and heated to high temperatures to bond with the wok's surface, creating a durable coating. Passivation uses chemical treatments such as nitric or citric acid to remove free iron and promote oxide formation, making the wok more resistant to oxidation. Proper maintenance of a carbon steel wok often involves curing for seasoning and periodic passivation for extended rust protection.

Benefits of Curing Your Carbon Steel Wok

Curing a carbon steel wok creates a durable, non-stick surface by polymerizing oil onto the metal, enhancing heat retention and cooking performance. This process protects the wok from rust and corrosion, extending its lifespan significantly compared to untreated steel. Unlike passivation, which primarily cleans and protects against oxidation, curing develops a seasoned layer essential for authentic stir-frying techniques.

Advantages of Passivation for Wok Longevity

| Passivation creates a protective oxide layer on carbon steel woks, enhancing corrosion resistance compared to curing methods. |

| The passivation process reduces the risk of rust formation, prolonging the wok's lifespan and maintaining its cooking performance. |

| Unlike curing, passivation requires less frequent maintenance, preserving the wok's structural integrity and seasoning quality over time. |

Step-by-Step Guide: How to Cure a Carbon Steel Wok

To cure a carbon steel wok, start by thoroughly washing it with warm water and mild soap to remove any factory oils or residues. Dry the wok completely before heating it on medium heat until it starts to smoke lightly.

Apply a thin layer of high-smoke-point oil, such as flaxseed or grapeseed oil, using a paper towel, then heat the wok until the oil polymerizes and forms a protective coating. Repeat the oiling and heating process 3-4 times to build a durable, non-stick surface that prevents rust and improves cooking performance.

How to Passivate a Carbon Steel Wok Properly

Passivating a carbon steel wok involves creating a thin layer of iron oxide to protect it from rust and enhance its longevity. To passivate properly, clean the wok thoroughly, then heat it until it changes color, followed by applying a thin coat of oil evenly across the surface and heating it again to polymerize the oil. This process forms a durable, rust-resistant patina essential for maintaining the wok's non-stick properties and ensuring optimal cooking performance.

Common Mistakes: Curing and Passivation Pitfalls

Improper curing can leave carbon steel woks susceptible to rust, while mistaken passivation attempts may strip protective oil layers. Understanding the distinct processes prevents surface damage and ensures long-term wok performance.

- Overheating during curing - Excessive heat can warp the wok and degrade seasoning quality, diminishing non-stick properties.

- Confusing passivation with seasoning - Passivation removes iron particles but does not replace the protective oil layer formed during curing.

- Insufficient oil application - Applying too little oil during curing exposes bare metal to oxidation and corrosion.

Related Important Terms

Blueing Layer Formation

Curing a carbon steel wok involves heating oil to create a durable, non-stick blueing layer by forming a polymerized oil film that bonds tightly to the metal surface, enhancing rust resistance and cooking performance. Passivation, by contrast, emphasizes chemical treatment to form a thin oxide layer primarily for corrosion resistance, but it does not develop the characteristic blueing layer essential for wok seasoning and longevity.

Reactive Iron Oxide Bonding

Curing a carbon steel wok promotes the formation of a reactive iron oxide layer that chemically bonds with oils, creating a durable, non-stick seasoning. In contrast, passivation focuses on creating a stable, inert oxide layer for corrosion resistance but lacks the reactive bonding necessary for the optimal seasoning of carbon steel cookware.

Thermal Polymerized Oil Matrix

Thermal polymerized oil matrix forms a durable, non-stick layer on carbon steel woks during the curing process, enhancing heat distribution and corrosion resistance. Unlike passivation, which creates a thin oxide layer, curing polymerizes the oil at high temperatures to produce a robust protective coating that improves cookware longevity.

Nitrided Seasoning Curing

Nitrided seasoning curing enhances the carbon steel wok's surface by creating a durable, corrosion-resistant layer through nitrogen infusion, offering superior protection compared to traditional passivation which primarily relies on oxide layer formation. This advanced curing method improves seasoning adhesion and longevity, ensuring a non-stick surface that resists rust and enhances cooking performance.

Controlled Flash Rusting

Controlled flash rusting enhances the curing process of carbon steel woks by forming a protective oxide layer that improves seasoning adherence and durability. Unlike passivation, which primarily prevents corrosion through chemical inhibition, controlled flash rusting leverages a rapid oxidation step to create a more robust, natural non-stick surface critical for wok performance.

Inert Gas Passivation

Inert gas passivation enhances carbon steel woks by forming a protective oxide layer without the risk of oxidation caused by traditional curing methods, thereby improving corrosion resistance and durability. This process uses nitrogen or argon to create a chemically stable surface, significantly extending the lifespan of carbon steel cookware compared to conventional heat curing techniques.

Deep Carbon Diffusion Seasoning

Deep carbon diffusion seasoning enhances curing by embedding carbon atoms into the steel surface, creating a durable, corrosion-resistant layer crucial for carbon steel wok longevity. Passivation primarily forms a thin oxide layer but lacks the depth and hardness improvements provided by curing through carbon infusion.

Passivation Film Recovery

Passivation enhances carbon steel wok durability by forming a protective oxide film that prevents rust during curing cycles. The recovery of the passivation film after curing ensures long-term corrosion resistance and preserves the wok's surface integrity under high-heat conditions.

Low-Temperature Phytic Acid Coating

Low-temperature phytic acid coating for carbon steel wok passivation offers a safer and eco-friendly alternative to traditional high-temperature curing by forming a stable, corrosion-resistant phosphorous-based layer without compromising the wok's structural integrity. This method enhances the wok's durability and non-reactivity, preventing rust and improving heat retention while maintaining its natural seasoning properties.

Curing vs Passivation for Carbon Steel Wok Infographic

cookingdiff.com

cookingdiff.com