Seasoned pans develop a natural non-stick layer through repeated use, making them ideal for curing as they prevent food from sticking and enhance flavor over time. Blue steel pans, known for their excellent heat retention and durability, require regular seasoning to maintain their non-stick properties and resist rust during the curing process. Choosing between the two depends on preference: seasoned pans offer immediate non-stick benefits, while blue steel pans provide robust performance with consistent care.

Table of Comparison

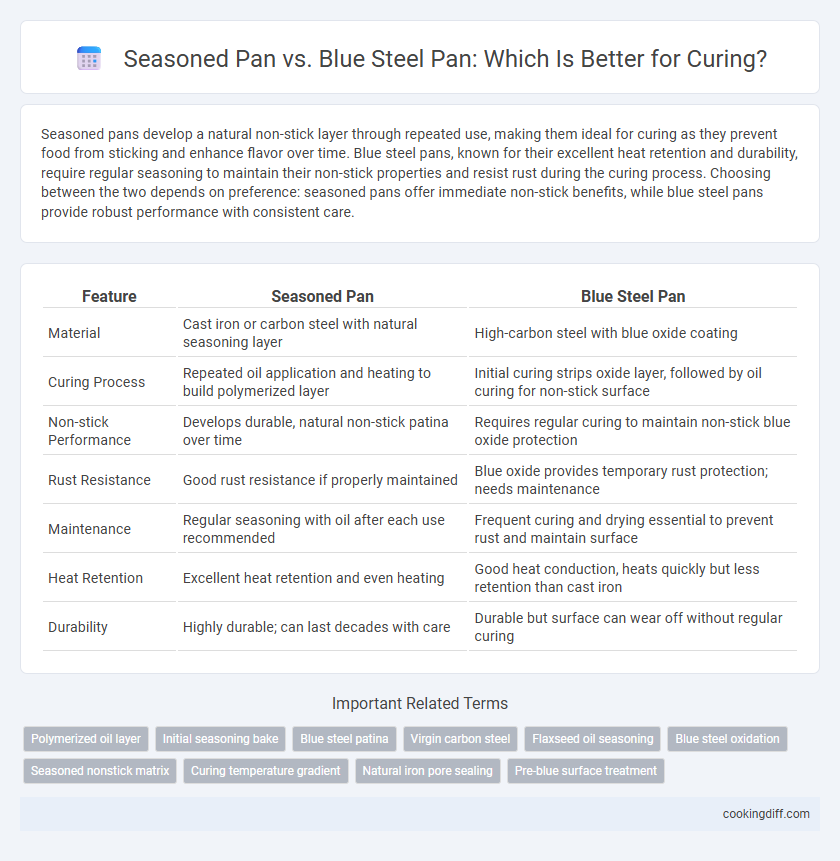

| Feature | Seasoned Pan | Blue Steel Pan |

|---|---|---|

| Material | Cast iron or carbon steel with natural seasoning layer | High-carbon steel with blue oxide coating |

| Curing Process | Repeated oil application and heating to build polymerized layer | Initial curing strips oxide layer, followed by oil curing for non-stick surface |

| Non-stick Performance | Develops durable, natural non-stick patina over time | Requires regular curing to maintain non-stick blue oxide protection |

| Rust Resistance | Good rust resistance if properly maintained | Blue oxide provides temporary rust protection; needs maintenance |

| Maintenance | Regular seasoning with oil after each use recommended | Frequent curing and drying essential to prevent rust and maintain surface |

| Heat Retention | Excellent heat retention and even heating | Good heat conduction, heats quickly but less retention than cast iron |

| Durability | Highly durable; can last decades with care | Durable but surface can wear off without regular curing |

Introduction to Pan Curing: Seasoned vs Blue Steel

What are the differences between a seasoned pan and a blue steel pan when it comes to curing? Seasoned pans develop a natural non-stick coating through layers of polymerized oil, enhancing flavor over time while offering rust resistance. Blue steel pans require regular maintenance and curing to build a protective patina, providing excellent heat retention and durability for cooking.

What is a Seasoned Pan?

A seasoned pan is a cooking vessel that has been treated with oil and heated to create a non-stick, rust-resistant surface through polymerization. This natural coating improves with use, enhancing flavor development and ease of cooking.

In contrast, blue steel pans require regular seasoning to maintain their protective layer and prevent rust. Seasoned pans offer a more durable and consistent non-stick surface, ideal for frying, sauteing, and curing processes. Their built-up seasoning also contributes to better heat retention and distribution compared to unseasoned blue steel pans.

Understanding Blue Steel Pans

Blue steel pans are preferred for curing due to their rapid heat responsiveness and durability compared to seasoned pans. Unlike seasoned pans, which develop a natural non-stick layer through repeated oil treatments, blue steel pans require regular maintenance to prevent rust. Their smooth surface enhances even seasoning layers, making them ideal for achieving consistent curing results.

Key Differences Between Seasoned and Blue Steel Pans

| Key Differences | Seasoned Pan | Blue Steel Pan |

|---|---|---|

| Curing Process | Develops a natural non-stick coating through oil polymerization; requires regular maintenance to maintain seasoning layers. | Starts with a protective blue oxide layer formed during heat treatment; needs curing but is less prone to rust compared to raw steel. |

| Surface Properties | Smooth, black patina forms over time enhancing food release and flavor; surface is slightly more delicate and requires gentle care. | Matte blue finish is harder and more resistant to corrosion initially; surface improves with use but tends to retain slight metallic taste if under-cured. |

| Durability and Maintenance | Requires periodic re-seasoning to avoid rust and maintain the protective layer; susceptible to damage if exposed to acidic foods extensively. | Better initial rust resistance; needs seasoning to improve non-stick capabilities but generally requires less frequent maintenance than seasoned pans. |

Heat Retention and Distribution: Seasoned vs Blue Steel

Seasoned pans offer excellent heat retention due to their polymerized oil coating, which creates a natural non-stick surface and evenly distributes heat. Blue steel pans heat up quickly and maintain high temperatures, providing superior heat responsiveness but slightly less consistent heat distribution compared to seasoned pans. Both types excel in heat management, with seasoned pans better for steady cooking and blue steel ideal for rapid temperature changes during curing.

Durability and Maintenance Comparison

Seasoned pans develop a natural non-stick layer through polymerized oil, which enhances durability by preventing rust and surface damage when properly maintained. Blue steel pans are also durable but require more frequent seasoning to maintain their protective layer and prevent oxidation.

Maintenance for seasoned pans involves regular oiling after cleaning to sustain the seasoning and ensure long-term use. Blue steel pans demand careful drying and immediate seasoning after each use to avoid rust and maintain performance over time.

Curing Process: Step-by-Step for Each Pan

The curing process for a seasoned pan involves applying a thin layer of oil and heating it until it polymerizes, creating a non-stick surface. Blue steel pans require repeated heating and oiling to build a durable patina that prevents rust and improves cooking performance.

- Seasoned Pan Step 1 - Clean the pan thoroughly and dry it completely before oiling.

- Seasoned Pan Step 2 - Apply a thin layer of high-smoke-point oil evenly over the surface.

- Blue Steel Pan Step 1 - Heat the pan until it reaches a moderate temperature, then add oil and spread it evenly.

Both pans benefit from multiple curing cycles to ensure a resilient and protective coating.

Ideal Foods for Each Pan Type

Seasoned pans develop a non-stick layer ideal for high-fat foods like bacon and eggs, enhancing flavor through the curing. Blue steel pans excel in even heat retention, making them perfect for searing steaks and frying vegetables without sticking.

- Seasoned Pan Ideal Foods - Fatty and delicate foods such as eggs and bacon cook well due to the non-stick surface.

- Blue Steel Pan Ideal Foods - High-heat searing of meats like steaks benefits from the pan's superior heat retention.

- Vegetables on Blue Steel - Even cooking and browning of vegetables are optimized by the pan's consistent heat distribution.

Pros and Cons: Seasoned Pan vs Blue Steel Pan

Seasoned pans develop a natural non-stick coating over time, enhancing flavor but requiring careful maintenance to prevent rust. Blue steel pans offer superior heat retention and are easier to season but may discolor with heavy use.

- Seasoned Pan Durability - Requires regular oiling and gentle cleaning to maintain the seasoning and avoid rust.

- Blue Steel Heat Performance - Provides even heat distribution, making it ideal for high-heat cooking and curing.

- Maintenance Complexity - Seasoned pans need more frequent upkeep compared to blue steel pans, which handle wear better but develop patina.

Related Important Terms

Polymerized oil layer

Seasoned pans develop a durable, polymerized oil layer through repeated heating and application of fats, creating a natural non-stick surface ideal for curing. Blue steel pans also form a protective polymerized oil layer when properly cured, but their smoother surface allows for quicker seasoning and often results in a more uniform, rust-resistant coating.

Initial seasoning bake

Seasoned pans develop a natural non-stick surface through polymerized oil layers during the initial seasoning bake, enhancing durability and rust resistance. Blue steel pans require more frequent curing cycles as their thinner oxide layer provides less initial protection compared to the thicker seasoning developed on a well-seasoned pan.

Blue steel patina

Blue steel pans develop a natural patina through curing that enhances their non-stick properties and provides superior rust resistance compared to seasoned pans. This blue steel patina forms a protective oxide layer that deepens with use, improving durability and flavor retention over time.

Virgin carbon steel

Virgin carbon steel pans develop a natural non-stick surface through seasoning, creating a durable patina that enhances with use and heat exposure, while blue steel pans, a variant of carbon steel treated with a blue oxide layer, require initial seasoning to protect against rust but offer faster heat responsiveness; both types benefit from proper curing to establish corrosion resistance and improve cooking performance. The curing process transforms the raw metal surface by polymerizing oils into a semi-permanent coating, critical for virgin carbon steel pans to prevent oxidation and optimize longevity compared to pre-treated blue steel counterparts.

Flaxseed oil seasoning

Flaxseed oil is widely regarded as the optimal choice for seasoning both seasoned pans and blue steel pans due to its high concentration of polyunsaturated fats, which polymerize into a durable, non-stick coating under heat. While seasoned pans benefit from repeated flaxseed oil applications for a resilient surface, blue steel pans achieve enhanced rust resistance and a naturally slick finish through the same curing process, making flaxseed oil essential for long-term maintenance.

Blue steel oxidation

Blue steel pans undergo a natural oxidation process that forms a protective blue-black patina, enhancing their resistance to rust and improving seasoning durability compared to seasoned pans. This oxidation layer acts as a natural non-stick surface, facilitating better curing and long-lasting cooking performance.

Seasoned nonstick matrix

Seasoned pans develop a durable, nonstick matrix through polymerized oils that create a natural, chemical-free coating ideal for curing and enhancing flavors over time. Blue steel pans offer excellent heat retention but require regular seasoning to maintain their nonstick properties and prevent rust during the curing process.

Curing temperature gradient

Seasoned pans develop a stable, polymerized oil layer through curing at temperatures typically between 180degC and 230degC, creating a non-stick surface that improves with use. Blue steel pans require a higher curing temperature gradient, often reaching up to 300degC, to form a durable, rust-resistant patina through controlled oxidation.

Natural iron pore sealing

Blue steel pans naturally seal iron pores during curing by developing a robust oxide layer that enhances rust resistance, whereas seasoned pans rely on polymerized oil layers to fill pores and create a non-stick surface. The iron pore sealing in blue steel is more durable and integral to the metal, providing longer-lasting protection compared to the surface coating of traditional seasoned pans.

Seasoned pan vs blue steel pan for curing. Infographic

cookingdiff.com

cookingdiff.com