Salt curing enhances the durability and hygiene of utensils by effectively removing moisture and preventing bacterial growth. Rice water curing, on the other hand, imparts a natural sheen and mild antibacterial properties while being gentle on delicate materials. Choosing between salt cure and rice water curing depends on the utensil's material and desired finish, balancing moisture control with surface care.

Table of Comparison

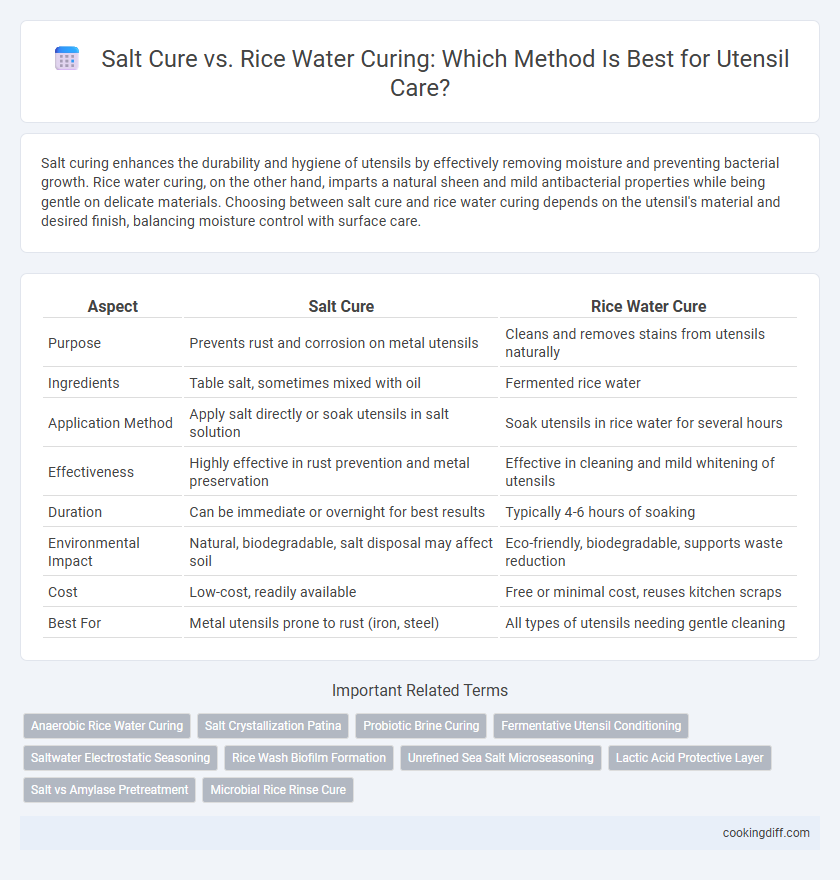

| Aspect | Salt Cure | Rice Water Cure |

|---|---|---|

| Purpose | Prevents rust and corrosion on metal utensils | Cleans and removes stains from utensils naturally |

| Ingredients | Table salt, sometimes mixed with oil | Fermented rice water |

| Application Method | Apply salt directly or soak utensils in salt solution | Soak utensils in rice water for several hours |

| Effectiveness | Highly effective in rust prevention and metal preservation | Effective in cleaning and mild whitening of utensils |

| Duration | Can be immediate or overnight for best results | Typically 4-6 hours of soaking |

| Environmental Impact | Natural, biodegradable, salt disposal may affect soil | Eco-friendly, biodegradable, supports waste reduction |

| Cost | Low-cost, readily available | Free or minimal cost, reuses kitchen scraps |

| Best For | Metal utensils prone to rust (iron, steel) | All types of utensils needing gentle cleaning |

Introduction to Curing Utensils

Curing utensils is an essential process to enhance their durability and prevent rusting or damage during initial use. Salt curing involves rubbing utensils with salt to remove residues and improve surface texture effectively.

Rice water curing, on the other hand, uses starchy water to create a protective coating on the utensil's surface, reducing stickiness and enhancing non-stick properties. Both methods prepare cookware for extended usage, but salt curing is preferred for metal utensils, while rice water suits cast iron and clay cookware better.

What is Salt Curing?

Salt curing is a preservation technique that involves applying salt to utensils to prevent rust and corrosion. This method utilizes the hygroscopic properties of salt to absorb moisture and inhibit microbial growth on metal surfaces.

Salt curing is highly effective for metal utensils exposed to humid environments, offering long-term protection against oxidation. The process is simple, cost-effective, and does not introduce chemicals that might degrade the utensil's material. Salt curing also enhances the durability of utensils by forming a protective layer that minimizes surface damage.

Understanding Rice Water Curing

What are the benefits of rice water curing compared to salt curing for utensils? Rice water curing enhances the longevity of utensils by forming a protective starch layer that reduces corrosion. This method is gentler on metals and helps maintain the utensil's surface integrity better than traditional salt curing.

Historical Background of Both Methods

Salt curing dates back thousands of years, originating in ancient civilizations such as Egypt and Rome where salt's preservative properties were highly valued. Rice water curing, rooted in Asian traditions, was historically used for its natural starch content to clean and preserve utensils without harsh chemicals.

- Salt Cure in Ancient Civilizations - Salt was essential for food preservation and utensil curing in early societies due to its antimicrobial effects.

- Rice Water Usage in Asia - Cultures in China and Japan utilized leftover rice water as a gentle, effective method to maintain and clean cooking vessels.

- Evolution of Techniques - Both methods evolved based on regional availability and cultural practices, influencing utensil care and hygiene over centuries.

Mechanisms: How Salt Cure Works

Salt curing preserves utensils by drawing out moisture through osmosis, inhibiting microbial growth. Salt's hygroscopic nature creates an environment unsuitable for bacteria and fungi, effectively preventing corrosion and spoilage.

- Moisture Extraction - Salt absorbs water from utensil surfaces, reducing dampness essential for microbial activity.

- Microbial Inhibition - High salt concentration disrupts microbial cell functions, limiting decay.

- Corrosion Prevention - Salt forms a protective dry layer that deters rust formation on metal utensils.

Salt curing offers a natural and robust method to extend the lifespan of utensils through moisture control and microbial suppression.

Mechanisms: How Rice Water Curing Works

Rice water curing works by creating a natural alkaline environment that helps to remove metallic residues and improve the durability of utensils. The starch and enzymes in rice water interact with the utensil surface, promoting a mild abrasive effect that cleans and strengthens the material.

This method contrasts with salt curing, which relies on the hygroscopic nature of salt to draw out moisture and inhibit bacterial growth. Rice water curing also enhances the utensil's resistance to corrosion by forming a protective layer on the surface, extending its lifespan.

Benefits & Drawbacks of Salt Curing

Salt curing for utensils effectively prevents corrosion by drawing out moisture and creating a protective barrier against rust. However, it can cause surface abrasion if not handled carefully, potentially damaging delicate materials over time. Salt residues may also require thorough cleaning to avoid contamination or taste alteration in food preparation.

Benefits & Drawbacks of Rice Water Curing

Rice water curing enhances utensil longevity by forming a natural protective layer that reduces corrosion and maintains the utensil's flavor integrity. This method is eco-friendly but may require longer curing times compared to salt curing.

- Eco-Friendly - Utilizes natural starches and nutrients from rice water, minimizing environmental impact.

- Flavor Preservation - Prevents metallic taste transfer better than salt curing, preserving the food's original flavors.

- Time-Consuming - Takes more time to complete the curing process, potentially delaying utensil usability.

Comparing Effectiveness: Salt vs. Rice Water

| Aspect | Salt Cure | Rice Water Cure |

|---|---|---|

| Effectiveness in Removing Impurities | Salt's abrasive texture effectively scrubs away metal residues and toxins, enhancing utensil safety. | Rice water contains starches and enzymes that cleanse naturally, though less abrasive than salt, it softens and preserves the metal surface. |

| Protection Against Rust | Salt can be corrosive if not properly rinsed, potentially leading to faster rust formation on utensils. | Rice water forms a protective biofilm that reduces oxidation, better preventing rust over time. |

| Eco-Friendliness | Salt is widely available but can contribute to environmental salt buildup if overused. | Rice water is biodegradable and sustainable, generating minimal environmental impact in curing processes. |

Related Important Terms

Anaerobic Rice Water Curing

Anaerobic rice water curing enhances utensil preservation by creating an oxygen-free environment that inhibits microbial growth more effectively than traditional salt curing, resulting in prolonged durability and improved hygiene. This method leverages the natural antimicrobial properties of fermented rice water, reducing corrosion and maintaining the utensil's surface integrity over extended periods.

Salt Crystallization Patina

Salt cure promotes robust salt crystallization patina formation on utensils, enhancing durability and antimicrobial properties by embedding a fine layer of salt crystals that prevent corrosion. In contrast, rice water curing creates a softer, starch-based protective film that lacks the crystalline structure, resulting in less effective corrosion resistance and reduced long-term protection.

Probiotic Brine Curing

Probiotic brine curing using salt enhances the preservation and microbial safety of utensils by promoting beneficial bacteria growth, unlike rice water curing which offers limited antimicrobial benefits. Salt cure's high salinity creates an inhospitable environment for pathogens, making it a superior method for long-term utensil hygiene and durability.

Fermentative Utensil Conditioning

Salt cure enhances fermentative utensil conditioning by creating a hypertonic environment that inhibits unwanted microbial growth, ensuring a cleaner fermentation process. Rice water curing promotes beneficial lactic acid bacteria development on utensils' surfaces, boosting probiotic qualities and improving fermentation consistency.

Saltwater Electrostatic Seasoning

Saltwater electrostatic seasoning enhances utensil curing by creating a uniform ionic layer that improves corrosion resistance and microbial inhibition, outperforming rice water curing which relies on natural starches for surface treatment. The electrostatic charge in salt cure ensures deeper penetration and longer-lasting protection, making it a more effective method for preserving metal and ceramic cookware.

Rice Wash Biofilm Formation

Rice water curing enhances biofilm formation on utensils by providing a nutrient-rich environment that promotes beneficial microbial growth, improving surface cleanliness and reducing pathogenic contamination. Salt curing, while effective as a dehydrating agent, lacks the organic substrates necessary to support robust biofilm development, resulting in less efficient microbial colonization and potential residue retention.

Unrefined Sea Salt Microseasoning

Unrefined sea salt microseasoning in salt curing penetrates utensils deeply, enhancing antimicrobial properties and imparting a natural mineral-rich flavor. Rice water curing, while effective for mild cleansing, lacks the potent preservation and seasoning benefits characteristic of salt curing with unrefined sea salt.

Lactic Acid Protective Layer

Salt curing enhances the formation of a robust lactic acid protective layer on utensils by promoting beneficial microbial fermentation, which inhibits rust and microbial growth. In contrast, rice water curing offers a milder lactic acid layer, providing moderate protection but lacking the effective antimicrobial properties found in salt curing.

Salt vs Amylase Pretreatment

Salt curing involves using sodium chloride to inhibit microbial growth and preserve utensils by creating a hypertonic environment, while rice water curing relies on amylase enzymes that break down starch residues, enhancing cleanliness and preventing contamination. Compared to salt pretreatment, amylase-rich rice water offers enzymatic action that targets organic residues more effectively, promoting thorough utensil sanitation without the corrosive effects associated with salt.

Salt cure vs rice water curing for utensils. Infographic

cookingdiff.com

cookingdiff.com