Smoke curing imparts a robust, smoky flavor and helps to preserve bacon by inhibiting bacterial growth, while beetroot curing enhances the meat with a natural sweetness and vibrant color due to its antioxidants and nitrates. Beetroot curing offers a more natural alternative by using vegetable-based ingredients without the addition of smoke compounds, making it appealing for health-conscious consumers. Both methods extend shelf life, but smoke curing is traditional and imparts a distinctive taste, whereas beetroot curing provides a milder, subtle flavor profile and a visually appealing hue.

Table of Comparison

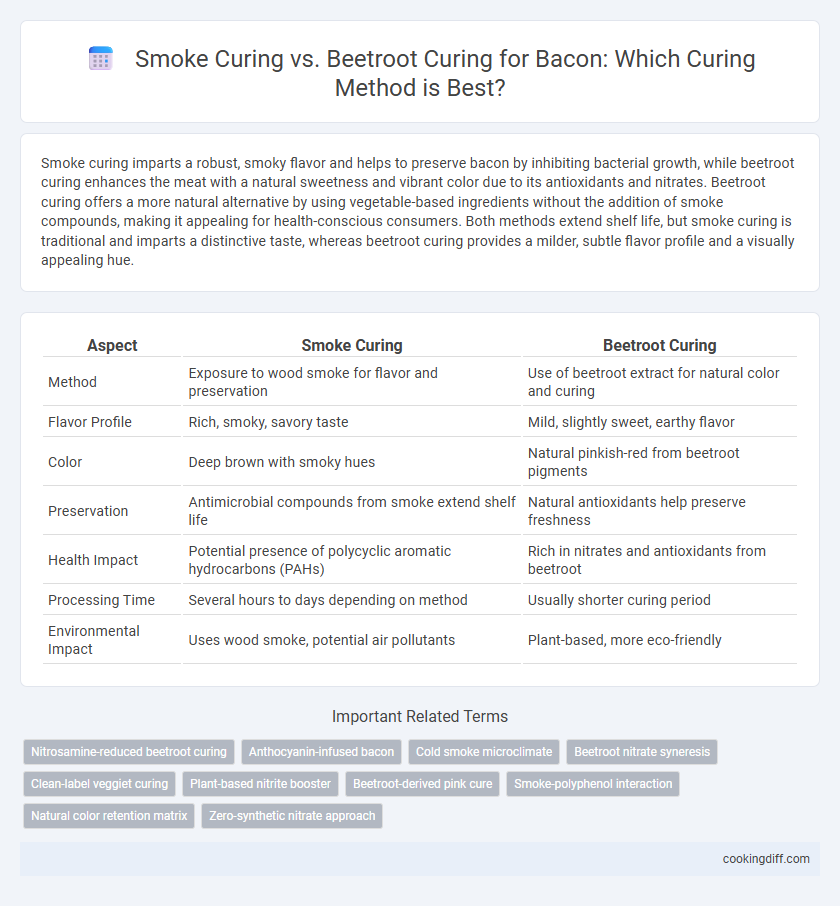

| Aspect | Smoke Curing | Beetroot Curing |

|---|---|---|

| Method | Exposure to wood smoke for flavor and preservation | Use of beetroot extract for natural color and curing |

| Flavor Profile | Rich, smoky, savory taste | Mild, slightly sweet, earthy flavor |

| Color | Deep brown with smoky hues | Natural pinkish-red from beetroot pigments |

| Preservation | Antimicrobial compounds from smoke extend shelf life | Natural antioxidants help preserve freshness |

| Health Impact | Potential presence of polycyclic aromatic hydrocarbons (PAHs) | Rich in nitrates and antioxidants from beetroot |

| Processing Time | Several hours to days depending on method | Usually shorter curing period |

| Environmental Impact | Uses wood smoke, potential air pollutants | Plant-based, more eco-friendly |

Introduction to Bacon Curing Methods

Bacon curing involves preserving and flavoring pork through specific methods to enhance taste and shelf life. Smoke curing and beetroot curing represent two distinct techniques that influence the bacon's flavor profile and color.

- Smoke Curing - Uses smoke particles from burning wood to impart a rich, smoky flavor and antibacterial properties.

- Beetroot Curing - Utilizes beetroot extract to naturally preserve the meat while adding a subtle sweetness and vibrant pink hue.

- Flavor Impact - Smoke curing delivers robust, savory notes whereas beetroot curing offers mild, earthy undertones and enhanced visual appeal.

Bacon curing methods vary significantly, shaping both the sensory qualities and preservation efficacy of the final product.

What is Smoke Curing?

Smoke curing is a traditional preservation method that involves exposing bacon to smoke from burning wood, which imparts distinct flavors and extends shelf life. The smoke contains compounds like phenols and formaldehyde that inhibit bacterial growth and enhance the meat's color and aroma.

Unlike beetroot curing, which uses natural sugars and pigments from beetroot to cure and color the bacon, smoke curing relies on chemical reactions from smoke exposure. This method is widely favored for its ability to produce a rich, smoky taste and firm texture in the finished product.

What is Beetroot Curing?

What is beetroot curing and how does it compare to traditional smoke curing for bacon? Beetroot curing uses natural beetroot juice to impart a vibrant color and subtle sweetness to bacon, serving as a natural alternative to chemical nitrates. This method enhances flavor while reducing the smoky aroma found in traditional smoke curing.

Flavor Profiles: Smoke vs Beetroot

Smoke curing infuses bacon with a rich, smoky flavor that is both robust and savory, enhancing its traditional taste profile. This method imparts deep, complex aromas derived from the combustion of hardwoods like hickory or applewood, creating a distinctive and intense smoky essence.

Beetroot curing, by contrast, imparts a mild, earthy sweetness to bacon, with subtle vegetal undertones that complement its natural saltiness. The use of beetroot also adds a unique reddish hue and a nuanced flavor complexity that is fresher and less overpowering than smoke curing.

Color and Visual Appeal Differences

Smoke curing imparts a rich, deep reddish-brown hue to bacon, enhancing its visual appeal with a glossy, slightly charred surface. Beetroot curing, in contrast, produces a vibrant pinkish-red color that appears more natural and less glossy, offering a visually striking alternative without the smoky overlay. The distinct coloration differences directly influence consumer perception, with smoke-cured bacon often perceived as traditional and robust, while beetroot-cured bacon appears fresh and visually unique.

Health Implications of Each Curing Method

Smoke curing bacon introduces polycyclic aromatic hydrocarbons (PAHs), which are linked to increased cancer risk, whereas beetroot curing uses natural nitrates and antioxidants, potentially offering a healthier alternative. Beetroot curing may reduce sodium content and enhance nutrient retention compared to traditional smoke curing. However, both methods require careful control of nitrate levels to avoid harmful nitrosamine formation.

Texture Comparison of Smoke-Cured and Beetroot-Cured Bacon

| Curing Method | Texture Characteristics |

|---|---|

| Smoke Curing | Produces a firm, slightly chewy texture with a crisp outer layer due to the application of smoke heat and drying effects. |

| Beetroot Curing | Results in a tender and moist texture as beetroot imparts natural sugars and moisture retention, softening the bacon's muscle fibers. |

| Comparison | Smoke-cured bacon is denser and chewier, while beetroot-cured bacon offers a smoother, juicier bite with less resistance when chewed. |

Ingredient and Equipment Requirements

Smoke curing bacon requires hardwood chips or charcoal for generating smoke, alongside a smoker or smokehouse appliance, while beetroot curing demands fresh beetroot and a refrigeration unit for controlled curing temperatures. Both methods need salt and sugar as primary curing agents but differ significantly in their ingredient profiles and equipment setup.

Smoke curing relies heavily on temperature regulation and smoke exposure equipment to impart flavor and preserve the bacon thoroughly. Beetroot curing involves enzymatic interactions facilitated by natural sugars in beetroot, necessitating precise refrigeration to prevent spoilage. Understanding these ingredient and equipment differences is essential for achieving desired bacon flavor and texture in the curing process.

Home Curing: Step-by-Step Guides

Smoke curing imparts a rich, smoky flavor to bacon by exposing it to wood smoke, enhancing preservation through antimicrobial compounds. Beetroot curing offers a natural alternative that uses beetroot's nitrates for color and mild flavor while maintaining moisture in the meat.

- Smoke Curing Process - Bacon is salted, air-dried, then cold or hot smoked over hardwood for several hours to infuse flavor.

- Beetroot Curing Process - Bacon is soaked in a beetroot-based brine, which introduces natural nitrates and a subtle sweetness during curing.

- Home Curing Highlights - Both methods require temperature control and time, but smoke curing needs additional equipment like a smoker, whereas beetroot curing relies on easily prepared brines.

Related Important Terms

Nitrosamine-reduced beetroot curing

Beetroot curing for bacon significantly reduces nitrosamine formation compared to traditional smoke curing by leveraging natural antioxidants and lower nitrate levels, enhancing food safety and flavor stability. Studies show beetroot-curing methods decrease harmful nitrosamine compounds by up to 70%, making it a healthier alternative in bacon processing.

Anthocyanin-infused bacon

Smoke curing imparts a rich, smoky flavor and enhances preservation through chemical reactions between smoke compounds and meat proteins, while beetroot curing infuses bacon with natural antioxidants like anthocyanins, contributing to vibrant color and potential health benefits by reducing oxidative stress. Anthocyanin-infused bacon from beetroot curing offers a unique sensory profile and may appeal to health-conscious consumers seeking functional foods with antioxidant properties.

Cold smoke microclimate

Cold smoke curing creates a low-temperature, low-humidity microclimate that inhibits bacterial growth while infusing bacon with complex smoky flavors, maintaining moisture balance better than beetroot curing. In contrast, beetroot curing relies on sugar and nitrates from beetroot to preserve meat, resulting in less intense smoke flavor and a higher risk of microbial activity due to comparatively warmer, more humid conditions.

Beetroot nitrate syneresis

Beetroot curing leverages natural nitrates that enhance syneresis, effectively reducing moisture content and promoting firmer bacon texture compared to traditional smoke curing. The high nitrate concentration in beetroot accelerates the curing reaction, improving color stability and extending shelf life while maintaining a cleaner flavor profile.

Clean-label veggiet curing

Smoke curing enhances bacon with distinctive smoky flavor and acts as a natural preservative, but beetroot curing offers a clean-label, plant-based alternative that imparts vibrant color and mild sweetness without artificial additives. Beetroot curing aligns with clean-label trends by reducing chemical use while maintaining moisture and tenderness in bacon.

Plant-based nitrite booster

Smoke curing typically relies on the natural antimicrobial and antioxidant properties of smoked compounds, whereas beetroot curing leverages the high nitrate content of beetroot as a plant-based nitrite booster to enhance bacon preservation and color development. The conversion of beetroot-derived nitrates into nitrites by bacterial action ensures effective curing while offering a cleaner label alternative to synthetic nitrites.

Beetroot-derived pink cure

Beetroot-derived pink cure offers a natural alternative to traditional smoke curing by providing nitrate content essential for preserving bacon's color and flavor without the smoky taste. This method enhances the visual appeal with a vibrant pink hue while maintaining food safety through nitrate conversion, distinguishing it from the intense, aroma-driven profile of smoke curing.

Smoke-polyphenol interaction

Smoke curing introduces polyphenols that act as natural antioxidants, enhancing bacon's flavor complexity and shelf stability through interaction with meat proteins and lipids. In contrast, beetroot curing primarily imparts color and sweetness but lacks the potent polyphenol-mediated antimicrobial and antioxidant effects characteristic of smoke curing.

Natural color retention matrix

Smoke curing enhances bacon's natural color retention by forming a protective matrix of phenolic compounds and carbonyls that stabilize myoglobin, whereas beetroot curing relies on betalain pigments, providing a vibrant red hue but less stable color over time. The smoke-induced Maillard reaction also contributes to deeper, longer-lasting color compared to the more chemically sensitive beetroot pigments which may degrade under heat or light exposure.

Smoke curing vs Beetroot curing for bacon. Infographic

cookingdiff.com

cookingdiff.com