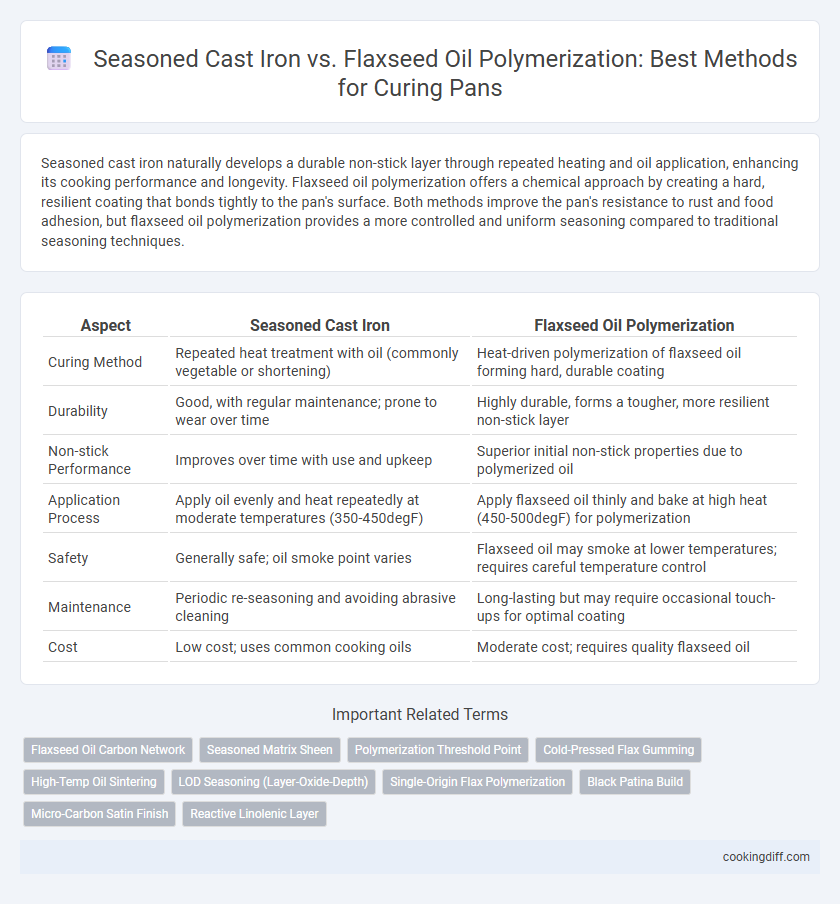

Seasoned cast iron naturally develops a durable non-stick layer through repeated heating and oil application, enhancing its cooking performance and longevity. Flaxseed oil polymerization offers a chemical approach by creating a hard, resilient coating that bonds tightly to the pan's surface. Both methods improve the pan's resistance to rust and food adhesion, but flaxseed oil polymerization provides a more controlled and uniform seasoning compared to traditional seasoning techniques.

Table of Comparison

| Aspect | Seasoned Cast Iron | Flaxseed Oil Polymerization |

|---|---|---|

| Curing Method | Repeated heat treatment with oil (commonly vegetable or shortening) | Heat-driven polymerization of flaxseed oil forming hard, durable coating |

| Durability | Good, with regular maintenance; prone to wear over time | Highly durable, forms a tougher, more resilient non-stick layer |

| Non-stick Performance | Improves over time with use and upkeep | Superior initial non-stick properties due to polymerized oil |

| Application Process | Apply oil evenly and heat repeatedly at moderate temperatures (350-450degF) | Apply flaxseed oil thinly and bake at high heat (450-500degF) for polymerization |

| Safety | Generally safe; oil smoke point varies | Flaxseed oil may smoke at lower temperatures; requires careful temperature control |

| Maintenance | Periodic re-seasoning and avoiding abrasive cleaning | Long-lasting but may require occasional touch-ups for optimal coating |

| Cost | Low cost; uses common cooking oils | Moderate cost; requires quality flaxseed oil |

Understanding Cast Iron Curing: Methods and Importance

What are the differences between seasoned cast iron and flaxseed oil polymerization methods for curing pans? Seasoned cast iron relies on the natural oils from cooking to build a durable non-stick surface over time. Flaxseed oil polymerization creates a hard, resin-like coating through repeated high-heat application, enhancing protection and longevity of the pan.

What Is Seasoned Cast Iron? Key Principles Explained

Seasoned cast iron involves creating a protective, non-stick coating through the polymerization of oils at high heat, enhancing pan durability and cooking performance. This process forms a layer of bonded oil molecules that repel moisture and prevent rust.

- Polymerization - High heat transforms oils like flaxseed or vegetable oil into a hard, durable coating on the pan surface.

- Seasoning Layers - Multiple thin layers build up a stronger, more effective non-stick surface over time.

- Protection - Proper seasoning prevents oxidation and corrosion, extending the cast iron's lifespan.

Flaxseed oil is popular for seasoning due to its high concentration of polyunsaturated fats, which polymerize efficiently during curing.

Flaxseed Oil Polymerization: The Science Behind the Hype

Flaxseed oil polymerization involves the oxidative drying process where the oil's polyunsaturated fatty acids react with oxygen, forming a durable, hard layer ideal for seasoning cast iron pans. This polymerized layer enhances non-stick performance and provides corrosion resistance by bonding molecularly to the iron surface.

The high concentration of alpha-linolenic acid in flaxseed oil accelerates cross-linking during curing, producing a smoother, more resilient seasoning compared to traditional oils. Scientific analysis confirms that flaxseed oil's unique chemical structure leads to a robust, long-lasting patina favored by experienced cast iron enthusiasts.

Traditional Seasoning Oils vs Flaxseed Oil: A Comparative Overview

| Traditional Seasoning Oils | Vegetable oils, shortening, and lard create durable, non-stick layers through thermal polymerization at medium heat. These oils contain a mix of saturated and unsaturated fats, promoting consistent seasoning longevity and rust resistance. Repeated application over time builds a resilient seasoning suited for varied cooking conditions. |

| Flaxseed Oil | High in polyunsaturated fats, flaxseed oil undergoes rapid polymerization to form a hard, thin seasoning layer with superior adhesion. Curing requires precise control of temperature and multiple thin coats to prevent flaking and ensure durability. Flaxseed oil seasoning is praised for its smooth finish but demands careful maintenance to sustain its performance. |

Pros and Cons of Seasoned Cast Iron Techniques

Seasoned cast iron offers a natural, durable non-stick surface created through the polymerization of fats and oils. This traditional curing method develops a patina over time, enhancing flavor and ease of cooking but requires regular maintenance to prevent rust.

- Durability - The seasoned layer strengthens with use, becoming more resilient against scratches and rust.

- Maintenance - Requires frequent cleaning without soap and periodic oiling to maintain the protective coating.

- Flavor enhancement - Seasoning builds a flavor-rich surface that improves the taste of dishes cooked on the pan.

Advantages and Drawbacks of Flaxseed Oil Polymerization

Flaxseed oil polymerization creates a durable, hard, and naturally non-stick layer on cast iron pans, enhancing seasoning longevity compared to traditional methods. However, it requires precise application and multiple thin coats to avoid sticky or uneven surfaces.

- High polymerization efficiency - Flaxseed oil forms a strong, cross-linked seasoning layer through rapid drying and polymerization.

- Susceptibility to uneven seasoning - Improper application or thick layers can cause tacky or flaky surfaces.

- Environmental sensitivity - Flaxseed oil-cured pans require controlled temperature and humidity during curing to avoid oxidation issues.

Seasoning Durability: Which Method Lasts Longer?

Seasoned cast iron develops a naturally durable, built-up layer of polymerized fats and oils that strengthens with repeated use and maintenance. Flaxseed oil polymerization creates an ultra-hard, smooth seasoning layer through multiple thin coats baked at high temperatures, offering superior initial durability. Over time, flaxseed oil seasoning typically lasts longer without chipping or flaking compared to traditional seasoning methods, making it ideal for longevity and performance.

Ease of Application: Seasoned Cast Iron vs Flaxseed Oil

Seasoned cast iron pans develop a natural non-stick surface through repeated cooking with oils and fats, requiring minimal effort in reapplication and maintenance. Flaxseed oil polymerization involves applying thin coats and baking at high temperatures, demanding careful timing and temperature control for optimal seasoning.

Ease of application favors seasoned cast iron as it builds up over time with regular use, making it user-friendly for home cooks. Flaxseed oil demands more precision but can create a hard, durable layer when properly applied, appealing to those seeking a more defined curing process.

Flavor Impact: Do Curing Methods Affect Cooking Results?

Seasoned cast iron pans develop a natural non-stick surface through polymerized oils, which subtly enhances food flavor by allowing even heat distribution and reducing metal interaction. Flaxseed oil polymerization creates a harder, more durable seasoning layer, often imparting a slightly nutty aroma that can influence the taste profile of dishes cooked on it.

Cooking results vary as the seasoning method affects the pan's surface texture and heat retention, thereby altering flavor release during cooking. Cast iron seasoned with traditional oils tends to produce richer, more complex flavors due to its porous, well-developed patina. Flaxseed oil-cured pans provide a more consistent, resilient surface that may slightly mute flavors but offers superior durability over time.

Related Important Terms

Flaxseed Oil Carbon Network

Flaxseed oil polymerization creates a strong carbon network on cast iron pans, forming a durable, non-stick surface that enhances seasoning longevity compared to traditional methods. This carbonized flaxseed oil layer resists flaking and improves heat retention, ensuring superior pan performance over time.

Seasoned Matrix Sheen

Seasoned cast iron showcases a durable seasoned matrix sheen achieved through repeated polymerization layers, creating a slick, non-stick surface that enhances cooking performance. Flaxseed oil polymerization offers a hard, glossy finish by forming a robust, cross-linked polymer matrix, but may require more maintenance to preserve the sheen compared to traditional seasoning methods.

Polymerization Threshold Point

Seasoned cast iron achieves a durable non-stick surface when the polymerization threshold point is reached, typically around 320degF (160degC), allowing oils to form a hard, protective layer. Flaxseed oil, with its high concentration of polyunsaturated fats, polymerizes effectively at this threshold, creating a resilient seasoning that enhances pan longevity and performance.

Cold-Pressed Flax Gumming

Cold-pressed flaxseed oil polymerizes through a process called cold-pressed flax gumming, creating a durable, hard seasoning layer on cast iron pans that is highly resistant to wear and sticking. Seasoned cast iron treated with flaxseed oil typically forms a smoother, more resilient coating compared to traditional oils due to the oil's high concentration of linolenic acid, which enhances the polymerization reaction during curing.

High-Temp Oil Sintering

Seasoned cast iron pans develop a durable, non-stick surface through polymerization, but flaxseed oil offers superior High-Temp Oil Sintering properties by forming a harder, more resilient seasoning layer. This high-temperature curing process creates a tightly bonded, oxidation-resistant coating that enhances pan longevity and cooking performance.

LOD Seasoning (Layer-Oxide-Depth)

Seasoned cast iron develops a thicker Layer-Oxide-Depth (LOD) through repeated seasoning cycles, creating a durable, non-stick surface that withstands high heat and abrasion. Flaxseed oil polymerization produces a harder, more brittle layer with a thinner LOD, offering superior initial adhesion but requiring careful maintenance to prevent cracking and flaking.

Single-Origin Flax Polymerization

Single-origin flaxseed oil polymerization creates a durable, non-stick seasoning layer on cast iron pans by undergoing a chemical transformation that forms a hard polymer coating. This process enhances the pan's resistance to rust and wear compared to traditional seasoned cast iron methods, providing a naturally smooth surface optimized for cooking performance.

Black Patina Build

Seasoned cast iron develops a durable black patina through repeated polymerization of oils that creates a non-stick, rust-resistant surface, while flaxseed oil polymerizes more efficiently due to its high concentration of polyunsaturated fatty acids, producing a harder, more resilient seasoning layer. Flaxseed oil's natural drying properties accelerate the black patina build, enhancing the pan's longevity and non-stick performance compared to traditional seasoning oils.

Micro-Carbon Satin Finish

Seasoned cast iron develops a durable, non-stick Micro-Carbon Satin Finish through traditional polymerization of natural fats, enhancing heat retention and surface hardness. Flaxseed oil polymerization creates a similar hard, smooth layer but requires precise heating control to prevent uneven curing and potential flaking.

Seasoned cast iron vs flaxseed oil polymerization for curing pans. Infographic

cookingdiff.com

cookingdiff.com