Vegetable oil rub creates a thicker, more durable seasoning layer on a wok due to its higher viscosity and better polymerization during curing. Grapeseed oil spritz, with its lighter consistency, allows for a more even, thinner coating that reduces sticky build-up and provides a smoother non-stick surface. Choosing between the two depends on whether a robust, long-lasting seasoning or a quick, even cure is desired for optimal wok performance.

Table of Comparison

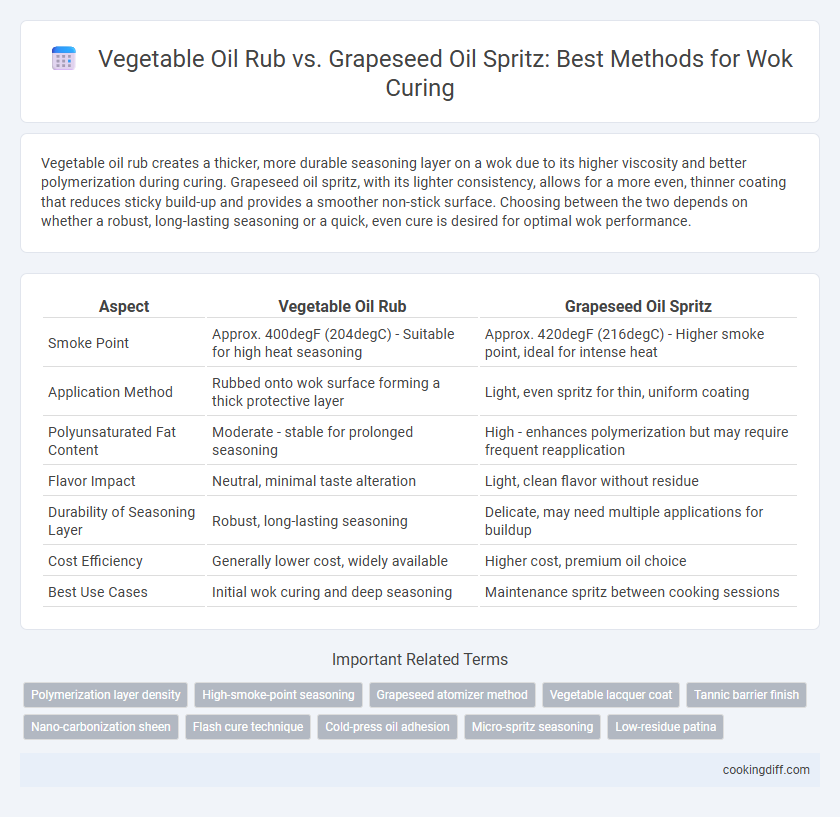

| Aspect | Vegetable Oil Rub | Grapeseed Oil Spritz |

|---|---|---|

| Smoke Point | Approx. 400degF (204degC) - Suitable for high heat seasoning | Approx. 420degF (216degC) - Higher smoke point, ideal for intense heat |

| Application Method | Rubbed onto wok surface forming a thick protective layer | Light, even spritz for thin, uniform coating |

| Polyunsaturated Fat Content | Moderate - stable for prolonged seasoning | High - enhances polymerization but may require frequent reapplication |

| Flavor Impact | Neutral, minimal taste alteration | Light, clean flavor without residue |

| Durability of Seasoning Layer | Robust, long-lasting seasoning | Delicate, may need multiple applications for buildup |

| Cost Efficiency | Generally lower cost, widely available | Higher cost, premium oil choice |

| Best Use Cases | Initial wok curing and deep seasoning | Maintenance spritz between cooking sessions |

Understanding Wok Curing: Basics and Importance

Vegetable oil rub creates a thicker, more durable seasoning layer on a wok by polymerizing fats through high heat, which enhances non-stick properties and prevents rust. Grapeseed oil spritz, with its high smoke point and lighter application, offers a quicker, more even coating that aids in gradual seasoning buildup without sticky residues.

Understanding wok curing involves recognizing the importance of repeated oil application and heating cycles to develop a resilient patina essential for cooking performance. Choosing between vegetable oil rub and grapeseed oil spritz depends on desired seasoning thickness, cooking frequency, and maintenance preferences for optimal wok longevity.

What Is a Vegetable Oil Rub?

A vegetable oil rub is a method of applying a thin layer of oil, such as canola or sunflower, onto a wok to create a protective seasoning layer. This technique helps prevent rust and enhances the non-stick properties of the cookware.

- Application Method - The oil is rubbed evenly across the wok's surface using a cloth or paper towel to ensure full coverage.

- Oil Selection - High smoke point vegetable oils are preferred to withstand the high temperatures involved in wok seasoning.

- Benefits - The rub forms a durable, polymerized coating that improves cooking performance and longevity of the wok.

Grapeseed Oil Spritz: A Modern Approach

Grapeseed oil spritz offers a lightweight, non-greasy coating ideal for wok curing, providing a high smoke point of approximately 420degF that helps create a durable, non-stick surface. This modern approach minimizes residue buildup compared to traditional vegetable oil rubs, ensuring a cleaner seasoning process and enhanced flavor retention.

Applying grapeseed oil as a fine mist promotes even coverage, accelerating oxidation and polymerization during heat treatment. Its neutral flavor and antioxidant properties make it a superior choice for maintaining wok integrity and improving long-term durability.

Smoke Points: Vegetable Oil vs Grapeseed Oil

Vegetable oil rub typically has a lower smoke point compared to grapeseed oil spritz, affecting the seasoning process of a wok. Grapeseed oil's higher smoke point makes it more suitable for high-heat curing methods, reducing the risk of burning the oil during seasoning.

- Vegetable oil smoke point - Generally ranges from 400degF to 450degF, which can lead to earlier smoking during wok curing.

- Grapeseed oil smoke point - Typically around 420degF to 485degF, offering better heat tolerance and less smoke production in curing.

- Heat management - Using grapeseed oil spritz allows for a more controlled and efficient seasoning layer on the wok surface.

Choosing grapeseed oil spritz over vegetable oil rub optimizes wok curing by leveraging its higher smoke point for better seasoning results.

Application Methods: Rubbing vs Spritzing

Rubbing vegetable oil directly onto the wok creates a thicker, more even seasoning layer that penetrates the metal, enhancing non-stick properties. Grapeseed oil spritzing offers a lighter, more controlled application, minimizing excess oil and reducing the risk of uneven polymerization.

Rubbing involves physically massaging the oil into the wok surface, which promotes strong adhesion and durability of the seasoning. Spritzing applies a fine mist, allowing for quick, uniform coverage but may require multiple layers for optimal protection. Both methods utilize oils with high smoke points, but selecting the application depends on desired seasoning texture and maintenance frequency.

Flavor Impact on Wok Seasoning

Vegetable oil rub imparts a rich, robust flavor that enhances the wok's seasoning through direct, even coating. Grapeseed oil spritz offers a lighter, neutral taste that preserves the natural flavors of ingredients cooked in the wok.

- Vegetable oil rub boosts flavor complexity - Its higher viscosity allows for better adherence and development of a deep, seasoned crust on the wok.

- Grapeseed oil spritz maintains seasoning subtlety - The fine mist distributes thinly, promoting a minimalist impact on flavor while preventing stickiness.

- Flavor longevity varies by oil type - Vegetable oil's bold flavor can intensify over multiple uses, whereas grapeseed oil retains a clean, unobtrusive seasoning profile.

Durability and Longevity of the Seasoning Layer

| Vegetable Oil Rub | Forms a thick, durable seasoning layer by polymerizing into a solid coating, enhancing longevity and corrosion resistance. Requires more time and heat to fully bond with the wok surface compared to spritz methods, resulting in a robust protective layer. Its viscosity allows deeper penetration into the metal's pores, improving seasoning adherence and durability over extended use. |

| Grapeseed Oil Spritz | Creates a thinner, more uniform seasoning layer with quicker polymerization due to high smoke point, though less durable than thicker rub coatings. The fine mist application promotes rapid drying and layering but may require frequent reapplication to maintain effective protection. Ideal for maintenance seasoning, it offers moderate longevity with easier touch-ups. |

Health Considerations: Oil Types Compared

Which oil offers better health benefits for wok curing, vegetable oil rub or grapeseed oil spritz? Vegetable oil rub often contains higher levels of saturated fats, which may impact heart health negatively over time. Grapeseed oil spritz is rich in polyunsaturated fats and vitamin E, supporting cardiovascular health and providing antioxidant properties during the curing process.

Practical Tips for Optimal Wok Curing

Vegetable oil rub creates a thicker, more durable seasoning layer on your wok, ideal for high-heat stir-frying. Grapeseed oil spritz offers a lighter, more even coating that polymerizes quickly due to its high smoke point, preventing food from sticking. For optimal wok curing, apply multiple thin layers of either oil, heating each coat to smoking point to build a non-stick, rust-resistant surface effectively.

Related Important Terms

Polymerization layer density

Vegetable oil rub forms a thicker, denser polymerization layer on the wok surface due to its higher saturated fat content, enhancing non-stick properties and durability. Grapeseed oil spritz creates a thinner, more even polymerized coating with faster drying, but the resulting layer is less dense and may require more frequent reapplication for optimal seasoning.

High-smoke-point seasoning

Vegetable oil rub offers a higher smoke point, typically around 400degF to 450degF, making it more effective for creating a durable, non-stick seasoning layer on woks. Grapeseed oil spritz, with a smoke point near 420degF, provides a lighter application but may require more frequent re-seasoning to maintain the high-smoke-point seasoning necessary for optimal wok performance.

Grapeseed atomizer method

Grapeseed oil spritz applied with an atomizer evenly coats the wok surface, promoting a thin, uniform layer that enhances polymerization and prevents sticky buildup during seasoning. This method ensures a faster curing process compared to vegetable oil rub by reducing excess oil pooling and creating a durable, non-stick patina.

Vegetable lacquer coat

Vegetable oil rub creates a durable vegetable lacquer coat on the wok surface, enhancing non-stick properties and preventing rust more effectively than grapeseed oil spritz. This thicker lacquer layer formed by vegetable oil seals pores in the metal, ensuring long-lasting protection and optimal heat distribution during cooking.

Tannic barrier finish

Vegetable oil rub creates a thicker tannic barrier finish on wok surfaces, enhancing rust resistance and durable seasoning compared to the lighter tannin layer produced by grapeseed oil spritz. The dense tannic coating from vegetable oil effectively seals pores and promotes superior non-stick properties during repeated curing cycles.

Nano-carbonization sheen

Vegetable oil rub creates a thicker, more uniform layer that promotes deeper nano-carbonization, resulting in a durable, glossy sheen ideal for wok curing. Grapeseed oil spritz, with its lighter application and higher smoke point, facilitates a subtler nano-carbonized surface that enhances non-stick properties without heavy buildup.

Flash cure technique

Flash curing with grapeseed oil spritz enhances wok seasoning by creating a thin, even polymerized layer due to its high smoke point and low viscosity. Vegetable oil rub, while effective for deeper seasoning, typically requires longer heat exposure, making grapeseed oil spritz the preferred method for rapid and uniform wok curing.

Cold-press oil adhesion

Cold-press vegetable oil rub demonstrates superior adhesion during wok curing, forming a consistent, protective layer that enhances seasoning durability. Grapeseed oil spritz, while lighter and less viscous, tends to evaporate quickly, resulting in weaker bonding and uneven seasoning development on the wok surface.

Micro-spritz seasoning

Micro-spritz seasoning with grapeseed oil enhances wok curing by delivering a fine, even coating that resists high heat and prevents sticking, compared to the thicker application of vegetable oil rub which can cause uneven seasoning. Grapeseed oil's high smoke point and neutral flavor make it ideal for repeated micro-spritz applications, promoting a durable, non-stick wok surface without overpowering the food's taste.

Vegetable oil rub vs grapeseed oil spritz for wok curing. Infographic

cookingdiff.com

cookingdiff.com