Traditional wok seasoning creates a natural non-stick surface by building layers of polymerized oil, enhancing flavor and preventing rust over time. Carbonized woks achieve a similar effect through repeated high-heat treatment that forms a protective carbon layer, offering durability and ease of maintenance. Both methods improve cooking performance, but traditional seasoning requires regular upkeep, while carbonization provides a more resilient, long-lasting coating.

Table of Comparison

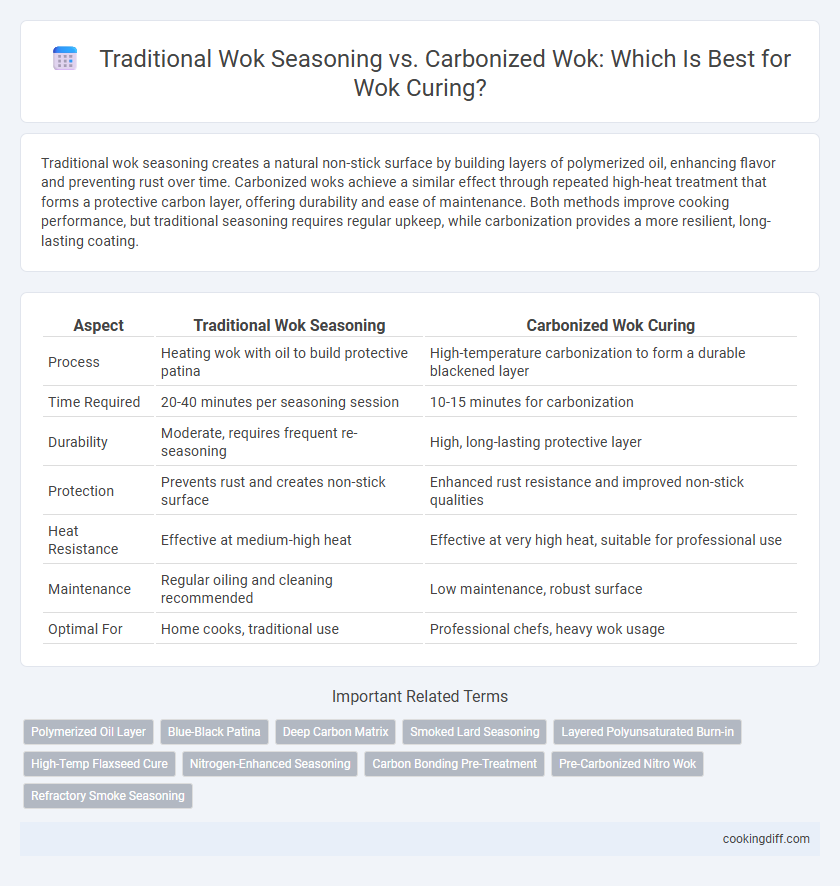

| Aspect | Traditional Wok Seasoning | Carbonized Wok Curing |

|---|---|---|

| Process | Heating wok with oil to build protective patina | High-temperature carbonization to form a durable blackened layer |

| Time Required | 20-40 minutes per seasoning session | 10-15 minutes for carbonization |

| Durability | Moderate, requires frequent re-seasoning | High, long-lasting protective layer |

| Protection | Prevents rust and creates non-stick surface | Enhanced rust resistance and improved non-stick qualities |

| Heat Resistance | Effective at medium-high heat | Effective at very high heat, suitable for professional use |

| Maintenance | Regular oiling and cleaning recommended | Low maintenance, robust surface |

| Optimal For | Home cooks, traditional use | Professional chefs, heavy wok usage |

Understanding Wok Curing: Importance in Cooking

Wok curing is essential to enhance the cooking performance and longevity of a wok by creating a natural non-stick surface. Traditional wok seasoning involves applying oil and heating gradually, whereas carbonized woks undergo intense high-heat treatment to form a protective layer.

- Traditional Wok Seasoning - This method builds layers of polymerized oil that improve flavor retention and prevent rust.

- Carbonized Wok - The carbonization process creates a hard, durable coating that enhances heat distribution and resistance to corrosion.

- Importance in Cooking - Properly cured woks ensure better heat retention, reduce food sticking, and extend the skillet's usability.

Understanding these curing techniques allows cooks to optimize their wok's performance for traditional Asian cooking methods.

What is Traditional Wok Seasoning?

Traditional wok seasoning is the process of coating a new wok with oil and heating it to create a protective, non-stick layer. This method removes factory oils and prevents rust, enhancing the wok's cooking performance and flavor development.

Seasoning involves heating the wok until it reaches a high temperature, then applying a thin layer of oil which polymerizes to form a durable coating. This natural patina improves with use, making the wok more resistant to food sticking and corrosion. Unlike carbonized woks, traditional seasoning relies on repeated heating cycles rather than high-temperature burning to build the surface layer.

The Process of Carbonizing a Wok

The process of carbonizing a wok involves heating the wok at extremely high temperatures until its surface develops a hard, blackened layer that enhances non-stick properties. This method differs from traditional seasoning, which relies on oil polymerization to create a protective coating over multiple uses. Carbonized woks offer increased durability and resistance to rust, making them ideal for heavy-duty cooking and long-term maintenance.

Material Differences: Carbon Steel vs Carbonized Surface

How do material differences between traditional carbon steel and carbonized surfaces impact wok curing effectiveness? Traditional woks made from carbon steel offer a uniform surface ideal for seasoning, promoting natural non-stick properties through polymerized oil layers. Carbonized wok surfaces exhibit enhanced durability and heat retention due to a hardened oxide layer, reducing maintenance during curing but requiring specific techniques to preserve the seasoned coating.

Step-by-Step Guide: Traditional Wok Seasoning Method

Traditional wok seasoning involves gradually building a natural, non-stick patina through repeated heating and oiling, essential for long-lasting durability and enhanced cooking performance. This step-by-step method ensures a well-seasoned carbon steel wok that improves food flavor and prevents rust.

- Clean the wok - Remove factory oil and residue by scrubbing with hot water and a mild detergent, then dry thoroughly.

- Heat the wok - Place the wok on high heat until it changes color, which helps open the metal pores for oil absorption.

- Apply oil and maintain heat - Rub a thin layer of high-smoke-point oil like flaxseed or vegetable oil onto the hot wok surface, heating until smoke appears, then wipe excess oil to begin the seasoning layer.

Carbonized Wok Preparation: Factory vs Home Treatment

Carbonized wok preparation involves a high-temperature factory process that creates a durable, blackened layer, enhancing non-stick properties and rust resistance. Factory treatment ensures uniform carbonization, reducing the risk of uneven curing often encountered in home environments.

Home treatment for carbonizing woks typically uses open flames or stovetop heating, which can result in inconsistent seasoning and potential warping if not carefully managed. Despite this, home methods allow for customizable seasoning based on individual cooking preferences and ingredients.

Flavor Development: Traditional vs Carbonized Woks

Traditional wok seasoning involves layering oil and heating repeatedly to develop a natural non-stick surface that enhances umami flavors during cooking. Carbonized woks, formed by controlled charring of the metal, create a robust seasoning layer that imparts a smoky depth and intensifies stir-fry aromas. Both methods contribute to flavor development, but carbonized woks often produce a more pronounced, complex taste profile due to the thicker patina.

Maintenance and Longevity: Which Cure Lasts Longer?

Traditional wok seasoning involves building a natural non-stick layer that requires regular maintenance to prevent rust and maintain performance. Carbonized wok curing creates a durable, heat-fused coating that offers longer-lasting protection with less frequent upkeep.

- Traditional seasoning durability - Needs periodic re-seasoning to sustain a protective, non-stick surface.

- Carbonized coating longevity - Provides a more robust layer resistant to wear and corrosion over extended use.

- Maintenance frequency - Traditional seasoning demands higher maintenance, while carbonized surfaces require minimal care for long-term durability.

Cooking Performance: Comparing Heat and Nonstick Qualities

| Wok Type | Heat Distribution | Nonstick Quality |

|---|---|---|

| Traditional Wok Seasoning | Provides even heat distribution due to multiple seasoning layers forming a stable patina. | Effective nonstick surface develops over time as seasoning polymerizes from oils during cooking. |

| Carbonized Wok | Offers rapid heat conduction with a naturally carbonized surface enhancing thermal responsiveness. | Nonstick properties are inherent but may require occasional oiling to maintain optimal cooking performance. |

Related Important Terms

Polymerized Oil Layer

Traditional wok seasoning creates a durable polymerized oil layer through repeated heating and oiling, forming a natural non-stick surface that enhances flavor and prevents rust. In contrast, curing a carbonized wok relies on the existing carbon layer to provide seasoning but requires careful maintenance to preserve the polymerized oils essential for long-term non-stick performance.

Blue-Black Patina

Traditional wok seasoning develops a durable blue-black patina through repeated heating and oil application, enhancing non-stick properties and imparting rich flavor to dishes. In contrast, carbonized wok surfaces achieve a similar protective layer but may lack the depth and uniformity of patina formed by traditional methods, impacting heat distribution and seasoning longevity.

Deep Carbon Matrix

Traditional wok seasoning creates a thin, uneven patina that offers limited non-stick properties and durability compared to a carbonized wok curing process. The deep carbon matrix formed during carbonized wok curing embeds layers of carbon into the metal surface, enhancing heat retention, corrosion resistance, and a highly effective, long-lasting non-stick coating.

Smoked Lard Seasoning

Smoked lard seasoning enhances wok curing by creating a natural, non-stick carbonized layer that outperforms traditional wok seasoning methods reliant on oil polymerization. Carbonized woks treated with smoked lard develop superior heat retention and flavor absorption, ensuring optimal cooking performance and durability.

Layered Polyunsaturated Burn-in

Traditional wok seasoning creates a protective layer through the polymerization of polyunsaturated oils, forming a durable, non-stick surface that enhances cooking performance over time. In contrast, carbonized woks rely on a burnt-in layer that lacks the chemically bonded polymer layers, resulting in less effective seasoning and increased susceptibility to rust and food sticking.

High-Temp Flaxseed Cure

High-temp flaxseed cure creates a durable, non-stick seasoning layer by polymerizing linolenic acid at temperatures above 450degF, contrasting traditional wok seasoning which relies on repeated oil heating and carbonization for protective coating. Unlike carbonized woks that develop uneven, brittle layers prone to flaking, the flaxseed method ensures a smooth, resistant patina that enhances wok longevity and cooking performance.

Nitrogen-Enhanced Seasoning

Nitrogen-enhanced seasoning accelerates the curing process by creating a more stable, non-stick surface in traditional wok seasoning, reducing the formation of carbonized layers that can chip easily. This method leverages nitrogen's protective properties to improve durability and resistance to rust compared to conventional carbonized wok curing techniques.

Carbon Bonding Pre-Treatment

Carbon bonding pre-treatment in carbonized wok curing creates a durable, non-stick surface by inducing a stable layer of carbonized material that integrates with the wok's metal structure, enhancing heat retention and resistance to rust. This process contrasts with traditional wok seasoning, which relies on polymerized oils that can wear off, offering less long-term durability and requiring more frequent maintenance.

Pre-Carbonized Nitro Wok

Pre-Carbonized Nitro Woks offer superior curing performance compared to traditional wok seasoning by utilizing advanced carbonization techniques that ensure even heat distribution and enhanced durability. This innovative pre-carbonization process reduces the need for repetitive seasoning, resulting in improved non-stick properties and easier maintenance over time.

Traditional Wok Seasoning vs Carbonized Wok for wok curing. Infographic

cookingdiff.com

cookingdiff.com