Salt rub curing involves applying coarse salt to the cast iron surface to remove rust and create a natural seasoning layer, enhancing non-stick properties and durability. Rice polish curing uses finely ground rice husks to polish the cast iron, which gently smooths the surface while building a protective seasoning without abrasion. Both methods effectively maintain cast iron, but salt rub curing is more abrasive and better for heavy rust, while rice polish curing offers a gentler, polishing effect for routine care.

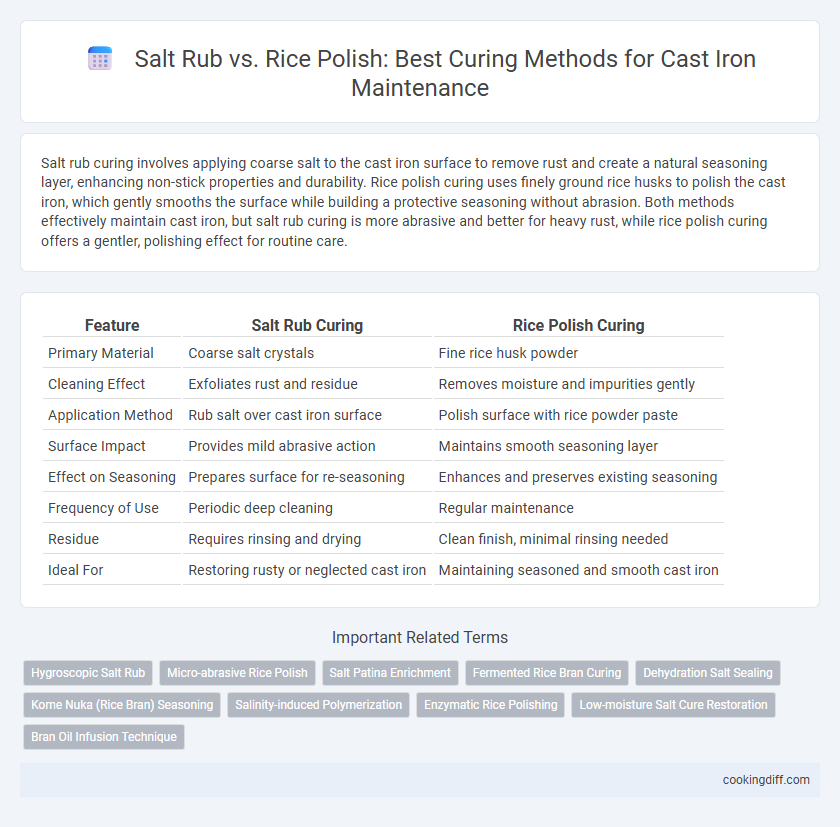

Table of Comparison

| Feature | Salt Rub Curing | Rice Polish Curing |

|---|---|---|

| Primary Material | Coarse salt crystals | Fine rice husk powder |

| Cleaning Effect | Exfoliates rust and residue | Removes moisture and impurities gently |

| Application Method | Rub salt over cast iron surface | Polish surface with rice powder paste |

| Surface Impact | Provides mild abrasive action | Maintains smooth seasoning layer |

| Effect on Seasoning | Prepares surface for re-seasoning | Enhances and preserves existing seasoning |

| Frequency of Use | Periodic deep cleaning | Regular maintenance |

| Residue | Requires rinsing and drying | Clean finish, minimal rinsing needed |

| Ideal For | Restoring rusty or neglected cast iron | Maintaining seasoned and smooth cast iron |

Introduction to Cast Iron Maintenance Techniques

Salt rub curing involves applying coarse salt to the cast iron surface to remove rust and impurities, enhancing seasoning adherence and durability. Rice polish curing uses finely ground rice husks to gently abrade and polish the cast iron, creating a smooth, non-stick surface while preserving the pan's seasoning. Both techniques improve cast iron longevity but offer distinct textures and maintenance benefits tailored to different cooking styles.

Understanding Salt Rub Curing

Salt Rub Curing involves applying coarse salt to the cast iron surface, which acts as an abrasive to remove rust and buildup without damaging the metal. This method enhances the seasoning by promoting a natural oil absorption into the pores of the cast iron, improving its non-stick properties and durability.

The process begins by sprinkling a generous layer of salt onto the cast iron skillet, followed by rubbing it with a cloth or potato to scrub away impurities. Salt's coarse texture effectively cleans while preserving the integrity of the cooking surface, unlike harsher chemical treatments. Regular use of Salt Rub Curing helps maintain a robust seasoning layer, ensuring even heating and extended lifespan of cast iron cookware.

Exploring Rice Polish Curing

Rice polish curing offers a natural, food-safe alternative to traditional salt rub curing for cast iron maintenance, enhancing the pan's seasoning without introducing abrasive elements. Rich in fine, mineral-laden particles, rice polish helps to build a smoother, more resilient non-stick surface that improves with each use.

This method creates a durable, corrosion-resistant layer by effectively sealing microscopic pores in the cast iron, reducing rust formation. Compared to salt rub curing, rice polish curing requires less frequent reapplication, making it a low-maintenance solution for preserving cast iron cookware longevity.

Key Differences Between Salt Rub and Rice Polish Methods

Salt rub curing involves applying coarse salt to the cast iron surface to remove rust and create a natural non-stick layer, while rice polish curing uses fine rice grain abrasive to smooth and polish the surface without heavy abrasion. Salt rub curing tends to be more abrasive and effective for heavy rust removal, whereas rice polish curing is gentler and enhances the cast iron's natural seasoning. Both methods improve cast iron longevity, but salt rub is preferred for restoration and rice polish for regular maintenance and refinement.

Effectiveness in Rust Removal

Salt rub curing is highly effective in removing rust by acting as a mild abrasive that scrubs away oxidation without damaging the cast iron surface. Rice polish curing, while gentler, provides a slower rust removal process by absorbing moisture and creating a protective layer that prevents further corrosion.

- Salt rub curing provides quick rust removal - coarse salt granules physically abrade and lift rust from the cast iron surface.

- Rice polish curing offers gradual moisture absorption - rice polish particles attract and trap moisture, reducing oxidation over time.

- Salt rub curing requires thorough rinsing - salt residues must be fully removed to avoid future corrosion, unlike rice polish which is less corrosive.

Impact on Cast Iron Surface Texture

Salt rub curing creates a slightly abrasive surface that helps remove rust and old seasoning, leaving a textured finish ideal for enhancing new seasoning layers. Rice polish curing produces a smoother, more uniform surface by gently polishing the cast iron, which can improve the pan's non-stick qualities over time.

- Salt Rub Curing Abrasiveness - This method physically scrubs the surface, promoting a rough texture that better adheres to oils during seasoning.

- Rice Polish Curing Smoothness - The fine grains in rice polish create a gentle buffing effect, smoothing out the cast iron's surface irregularities.

- Texture Impact on Seasoning - A textured surface from salt rub curing enhances seasoning retention, while a polished surface from rice curing optimizes cooking performance by reducing food adhesion.

Flavor and Odor Implications

| Salt Rub Curing | Enhances cast iron seasoning by drawing out moisture and food residue, which can result in a sharper, more pronounced metallic flavor over time. |

| Rice Polish Curing | Utilizes fine rice bran oils that create a smoother, more neutral odor and subtle flavor profile, reducing the risk of off-putting smells during cooking. |

| Flavor and Odor Implications | Salt curing may intensify lingering odors and metallic tastes, whereas rice polish promotes a cleaner surface, preserving food flavor integrity and minimizing unwanted odors. |

Suitability for Different Cast Iron Uses

Which curing method is best suited for different cast iron uses? Salt rub curing excels in seasoning cookware for high-heat cooking by creating a durable, non-stick surface. Rice polish curing is ideal for delicate cast iron pieces, offering a gentle, protective layer that prevents rust without compromising seasoning quality.

Sustainability and Ingredient Availability

Salt rub curing uses natural salt crystals to draw out moisture and create a protective layer, offering a sustainable method with widely available, inexpensive ingredients. This technique minimizes chemical use and reduces waste, aligning well with eco-friendly cast iron maintenance practices.

Rice polish curing involves applying finely ground rice bran oil or powder, which provides antioxidant properties and enhances seasoning durability, but ingredient availability may vary by region. While effective, rice polish curing may require sourcing specialty products that could impact sustainability depending on production methods and packaging.

Related Important Terms

Hygroscopic Salt Rub

Salt rub curing for cast iron leverages the hygroscopic properties of salt to draw out moisture and prevent rust effectively, enhancing the pan's seasoning by creating a dry, protective surface layer. In contrast, rice polish curing primarily provides a fine abrasive action to remove residue but lacks the moisture-absorbing benefits essential for long-term rust prevention.

Micro-abrasive Rice Polish

Micro-abrasive Rice Polish curing provides a gentle yet effective method for cast iron maintenance by removing surface residues without damaging the seasoning layer, enhancing durability and non-stick properties. Compared to salt rub curing, which relies on coarse abrasion that can strip seasoning prematurely, rice polish offers a refined texture that preserves the pan's integrity while improving cleanliness and longevity.

Salt Patina Enrichment

Salt Rub Curing enhances cast iron maintenance by forming a robust, corrosion-resistant salt patina that penetrates the metal surface, significantly improving durability and natural non-stick properties. In contrast, Rice Polish Curing relies on abrasive polishing to create a smoother finish but lacks the chemical patina enrichment provided by salt, resulting in less effective long-term protection against rust.

Fermented Rice Bran Curing

Fermented Rice Bran Curing enhances cast iron maintenance by forming a durable, natural non-stick layer rich in antioxidants, outperforming traditional Salt Rub Curing which primarily relies on abrasive cleaning and can strip seasoning. This method promotes longer-lasting rust protection and improved seasoning adherence through the enzymatic activity in the rice bran, making it a superior choice for preserving cast iron cookware.

Dehydration Salt Sealing

Salt rub curing enhances cast iron maintenance by creating a dehydration salt seal that effectively prevents moisture intrusion and rust formation, extending the cookware's lifespan. Rice polish curing also offers a natural abrasive and protective layer but lacks the superior moisture-excluding properties of salt rub curing, making the latter more efficient for long-term rust prevention.

Kome Nuka (Rice Bran) Seasoning

Salt rub curing effectively removes moisture and prevents rust on cast iron surfaces by drawing out impurities and forming a protective layer, while rice polish curing using Kome Nuka (rice bran) seasoning provides a natural, mild abrasive that enhances seasoning durability and adds a subtle, non-toxic coating to the pan. Kome Nuka's antioxidant properties help maintain the cast iron's integrity by reducing oxidation and promoting a long-lasting, smooth cooking surface.

Salinity-induced Polymerization

Salt Rub Curing promotes salinity-induced polymerization through direct contact with salt, enhancing the formation of a durable, corrosion-resistant polymer layer on cast iron surfaces. Rice Polish Curing relies on fine abrasive particles mixed with mild salts, inducing a more controlled and uniform polymerization that preserves the seasoning while minimizing surface wear.

Enzymatic Rice Polishing

Enzymatic rice polishing enhances cast iron maintenance by gently removing residues and preventing rust without abrasive damage, unlike salt rub curing which can cause micro-scratches and uneven seasoning. This bio-catalytic process improves seasoning adherence and extends pan longevity through natural enzymatic action that preserves the iron's surface integrity.

Low-moisture Salt Cure Restoration

Salt rub curing effectively removes moisture and rust from cast iron surfaces by creating a low-moisture environment that inhibits corrosion and promotes a durable seasoning layer. Rice polish curing offers a mild abrasive action that gently cleans and polishes the cast iron while maintaining the seasoning, but salt rub curing excels in low-moisture restoration by enhancing moisture extraction and surface preservation.

Salt Rub Curing vs Rice Polish Curing for cast iron maintenance. Infographic

cookingdiff.com

cookingdiff.com