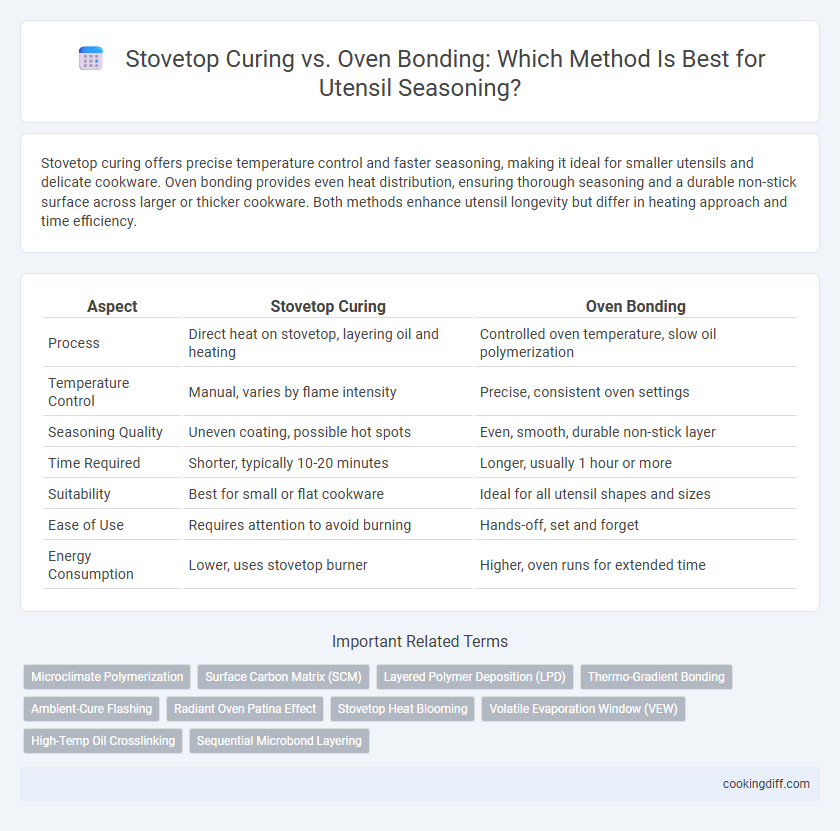

Stovetop curing offers precise temperature control and faster seasoning, making it ideal for smaller utensils and delicate cookware. Oven bonding provides even heat distribution, ensuring thorough seasoning and a durable non-stick surface across larger or thicker cookware. Both methods enhance utensil longevity but differ in heating approach and time efficiency.

Table of Comparison

| Aspect | Stovetop Curing | Oven Bonding |

|---|---|---|

| Process | Direct heat on stovetop, layering oil and heating | Controlled oven temperature, slow oil polymerization |

| Temperature Control | Manual, varies by flame intensity | Precise, consistent oven settings |

| Seasoning Quality | Uneven coating, possible hot spots | Even, smooth, durable non-stick layer |

| Time Required | Shorter, typically 10-20 minutes | Longer, usually 1 hour or more |

| Suitability | Best for small or flat cookware | Ideal for all utensil shapes and sizes |

| Ease of Use | Requires attention to avoid burning | Hands-off, set and forget |

| Energy Consumption | Lower, uses stovetop burner | Higher, oven runs for extended time |

Introduction to Utensil Seasoning Methods

Stovetop curing involves heating the utensil directly on a burner to polymerize oils, creating a durable, non-stick layer. Oven bonding uses controlled, uniform heat to evenly season cookware, enhancing longevity and performance.

Stovetop methods offer quicker results and are ideal for spot treatments, while oven seasoning ensures consistent coverage across the entire surface. Selecting the appropriate method depends on the utensil type and desired seasoning durability.

What Is Stovetop Curing?

| Stovetop curing involves heating a seasoned utensil directly on a burner, allowing the oil to polymerize and bond with the metal surface through gradual temperature control. This method provides precise heat management, preventing overheating and ensuring even seasoning layers. Stovetop curing is ideal for maintaining cast iron and carbon steel cookware seasoning integrity without the need for an oven. |

Oven Bonding Explained

Oven bonding for utensil seasoning involves heating the cookware at a consistent temperature, typically between 350-450degF, to ensure even polymerization of the oil. This method creates a durable, non-stick layer by penetrating the metal's surface more effectively than stovetop curing. The controlled environment in the oven prevents hot spots, resulting in a longer-lasting seasoning that enhances cooking performance and extends utensil lifespan.

Key Differences: Stovetop vs Oven Seasoning

Stovetop curing applies direct heat to evenly bond seasoning layers on utensils, promoting quick polymerization of oils. Oven bonding uses consistent ambient heat to create a more uniform seasoning, enhancing long-term durability and resistance to rust.

- Heat Application - Stovetop curing involves direct contact heat, while oven bonding exposes utensils to steady, surrounding heat.

- Seasoning Uniformity - Oven bonding achieves more even seasoning layers compared to the potentially uneven stovetop method.

- Durability - Oven-bonded seasoning typically results in more robust and long-lasting utensil protection.

Choosing between stovetop curing and oven bonding depends on the desired seasoning speed and quality for cookware maintenance.

Pros and Cons of Stovetop Curing

What are the advantages and disadvantages of stovetop curing for utensil seasoning? Stovetop curing allows precise temperature control and faster seasoning compared to oven bonding, making it ideal for quick touch-ups. However, it may result in uneven coating and requires constant attention to prevent overheating or burning the seasoning layer.

Benefits and Drawbacks of Oven Bonding

Oven bonding for utensil seasoning ensures even heat distribution, enhancing the durability and non-stick properties of the cookware. This method reduces the risk of hot spots and warping compared to stovetop curing, making it ideal for thick or cast iron utensils. However, oven bonding requires longer curing times and higher energy consumption, which may not be practical for quick seasoning tasks.

Effect on Utensil Surface and Longevity

Stovetop curing directly heats the utensil surface, promoting faster oil polymerization that enhances seasoning adhesion and creates a more durable non-stick layer. This method improves longevity by forming a robust, uneven surface that resists peeling and wear during use.

Oven bonding provides consistent, even heat distribution, resulting in uniform seasoning that strengthens the utensil surface over time. The controlled temperature environment in oven curing aids in developing a stable seasoning, extending the overall lifespan of the utensil.

Time, Temperature, and Technique Comparison

Stovetop curing typically requires lower temperatures around 300degF and shorter times of 10-15 minutes, using direct heat for more precise control. Oven bonding usually involves higher temperatures between 350-400degF for 1 hour, ensuring even seasoning across the utensil surface.

Temperature consistency is better maintained in oven bonding, reducing the risk of uneven seasoning or burnt spots common in stovetop curing. The stovetop method allows for quicker seasoning but demands constant attention to avoid overheating. Oven curing promotes a more durable and evenly distributed seasoning layer due to controlled heat distribution and longer curing duration.

Best Practices for Optimal Seasoning Results

Curing utensils on a stovetop allows for precise heat control, promoting even seasoning layers. Oven bonding ensures consistent, surrounding heat that deeply polymerizes the oil for durable non-stick surfaces.

- Use medium heat on the stovetop - Prevents overheating and uneven seasoning patches.

- Preheat the oven to 350-400degF - Achieves thorough oil polymerization and bonding.

- Apply thin, even oil layers - Enhances seasoning durability and prevents sticky residue.

Related Important Terms

Microclimate Polymerization

Stovetop curing creates a controlled microclimate that facilitates polymerization by maintaining localized high heat and moisture, enhancing seasoning adhesion on utensils. Oven bonding ensures even heat distribution but lacks the microclimate dynamics critical for optimal polymer layer formation during utensil seasoning.

Surface Carbon Matrix (SCM)

Stovetop curing promotes a gradual formation of a robust Surface Carbon Matrix (SCM) through controlled heat and oil polymerization, enhancing utensil seasoning durability. Oven bonding achieves a more uniform SCM layer by evenly distributing heat, reducing hotspots and ensuring consistent seasoning coverage.

Layered Polymer Deposition (LPD)

Stovetop curing facilitates precise control of temperature, promoting consistent Layered Polymer Deposition (LPD) for durable utensil seasoning by gradually polymerizing oils into a hardened, non-stick surface. Oven bonding, while offering uniform heat distribution, may accelerate polymerization unevenly, risking incomplete LPD layers and less resilient seasoning over time.

Thermo-Gradient Bonding

Thermo-gradient bonding in stovetop curing creates a precise heat distribution, promoting deeper polymerization of oil layers for durable seasoning. Oven bonding offers uniform heat but lacks the dynamic thermal gradients that enhance pore infiltration and adhesion strength in utensils.

Ambient-Cure Flashing

Ambient-cure flashing enhances stovetop curing by accelerating the polymerization of seasoning oils at lower temperatures, producing a more durable and evenly bonded utensil surface. Oven bonding requires precise temperature control to avoid overheating, whereas stovetop curing with ambient-cure flashing offers a flexible, energy-efficient method that improves adhesion and longevity of the seasoning layer.

Radiant Oven Patina Effect

Stovetop curing provides direct heat application, ideal for rapid seasoning but may result in uneven patina development on cookware surfaces. Radiant oven patina effect from oven bonding offers consistent, uniform seasoning by evenly distributing dry heat, enhancing utensil durability and non-stick properties through gradual polymerization of oils.

Stovetop Heat Blooming

Stovetop curing utilizes direct heat to achieve heat blooming, which enhances the seasoning layer's adhesion and durability by opening the utensil's pores for better oil absorption. This method allows precise temperature control, leading to a more uniform polymerization of the seasoning compared to oven bonding.

Volatile Evaporation Window (VEW)

Stovetop curing offers a controlled Volatile Evaporation Window (VEW) that allows gradual release of solvents and oils, enhancing seasoning durability and adherence on utensils. Oven bonding, by maintaining a consistent temperature, optimizes the VEW to uniformly evaporate volatiles, resulting in a smoother, more resilient seasoning layer.

High-Temp Oil Crosslinking

Stovetop curing enhances high-temp oil crosslinking by applying direct, controlled heat that promotes polymerization and durable seasoning layers on utensils. Oven bonding ensures even, consistent temperatures ideal for thorough curing, resulting in superior non-stick, corrosion-resistant surfaces.

Stovetop curing vs oven bonding for utensil seasoning. Infographic

cookingdiff.com

cookingdiff.com