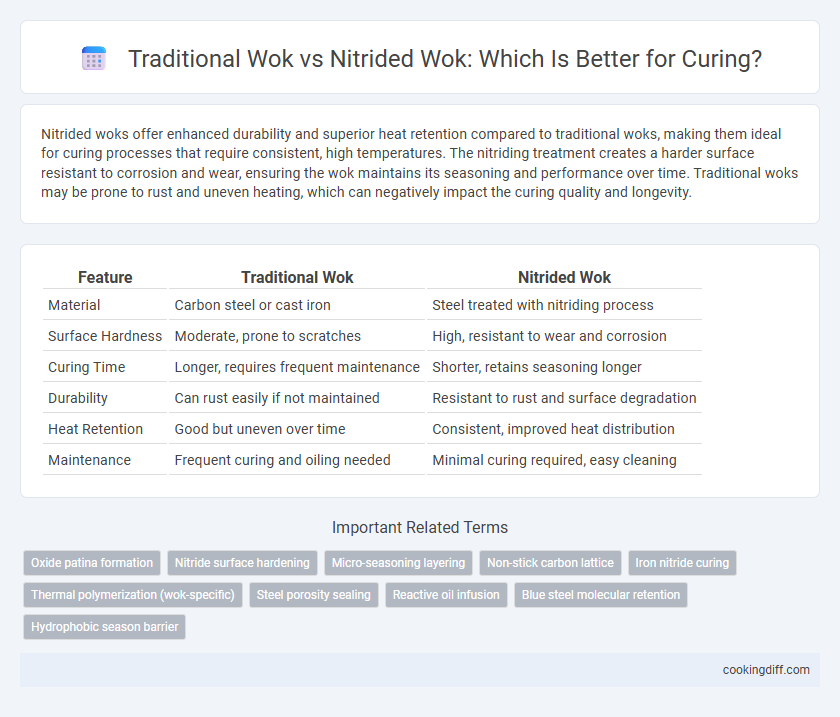

Nitrided woks offer enhanced durability and superior heat retention compared to traditional woks, making them ideal for curing processes that require consistent, high temperatures. The nitriding treatment creates a harder surface resistant to corrosion and wear, ensuring the wok maintains its seasoning and performance over time. Traditional woks may be prone to rust and uneven heating, which can negatively impact the curing quality and longevity.

Table of Comparison

| Feature | Traditional Wok | Nitrided Wok |

|---|---|---|

| Material | Carbon steel or cast iron | Steel treated with nitriding process |

| Surface Hardness | Moderate, prone to scratches | High, resistant to wear and corrosion |

| Curing Time | Longer, requires frequent maintenance | Shorter, retains seasoning longer |

| Durability | Can rust easily if not maintained | Resistant to rust and surface degradation |

| Heat Retention | Good but uneven over time | Consistent, improved heat distribution |

| Maintenance | Frequent curing and oiling needed | Minimal curing required, easy cleaning |

Introduction to Wok Curing: Importance and Methods

What distinguishes traditional woks from nitrided woks in the curing process? Traditional wok curing involves seasoning with oil to create a natural non-stick layer, enhancing flavor and preventing rust. Nitrided woks undergo a chemical treatment that forms a hardened surface, improving durability and heat retention during cooking.

What is a Traditional Wok? Composition and Properties

A traditional wok is typically made from carbon steel, known for its excellent heat conductivity and durability. Its thin, lightweight composition allows for quick temperature changes, essential for stir-frying and curing processes. The seasoned surface of a carbon steel wok develops a natural non-stick layer, enhancing flavor and preventing food from sticking during curing.

Understanding Nitrided Woks: Unique Features Explained

Nitrided woks undergo a specialized surface treatment that infuses nitrogen into the metal, enhancing durability and resistance to corrosion compared to traditional woks. This process creates a harder, non-stick surface that improves heat retention and ensures even cooking during curing.

- Enhanced Hardness - Nitriding significantly increases the wok's surface hardness, making it more resistant to scratches and wear.

- Corrosion Resistance - The nitrogen infusion protects the wok from rust and chemical reactions, extending its lifespan.

- Improved Heat Distribution - Nitrided woks offer superior heat retention and distribution, crucial for consistent curing results.

Key Differences Between Traditional and Nitrided Woks

Traditional woks are typically made from carbon steel or cast iron, which require regular seasoning to build a natural non-stick surface critical for curing food evenly. Nitrided woks undergo a nitrogen diffusion process that enhances surface hardness and corrosion resistance, reducing the need for frequent seasoning and improving durability. The nitrided layer also promotes better heat retention and distribution, resulting in more consistent curing outcomes compared to traditional woks.

Surface Chemistry: How Materials Affect Curing

The surface chemistry of traditional woks, typically made from carbon steel, allows for natural polymerization of oils during curing, creating a seasoned patina that enhances non-stick properties. Nitrided woks, treated with nitrogen to form a hard surface layer, exhibit increased resistance to corrosion and a more stable curing process through altered surface interactions.

- Traditional wok surface - Porous carbon steel enables oil absorption and polymerization, aiding in effective seasoning during curing.

- Nitrided wok surface - Nitrogen infusion creates a denser, harder surface that reduces reactive sites, changing the curing chemical dynamics.

- Impact on curing - Surface chemistry differences influence the rate and quality of oil polymerization, affecting durability and cooking performance.

Material surface properties critically determine the efficiency and outcome of the curing process in cookware.

Heat Retention and Distribution: Impact on Curing Process

Traditional woks excel in rapid heat distribution but tend to lose heat quickly, affecting consistent curing. Nitrided woks offer superior heat retention and even distribution, enhancing the uniformity and efficiency of the curing process.

- Heat Retention - Nitrided woks maintain higher temperatures for longer periods, ensuring steady curing.

- Heat Distribution - Traditional woks provide quick, uneven heat spread, potentially causing inconsistent curing.

- Impact on Curing - Consistent heat retention and distribution in nitrided woks improve curing quality and texture uniformity.

Ease of Curing: Step-by-Step Comparison

| Aspect | Traditional Wok | Nitrided Wok |

|---|---|---|

| Initial Cleaning | Requires thorough scrubbing to remove factory oils and residues before curing. | Less intensive cleaning needed due to nitriding process reducing surface impurities. |

| Seasoning Process | Multiple layers of oil application and heating cycles needed for creating a non-stick surface. | Faster seasoning with fewer oil layers due to enhanced surface hardness and oxidation resistance. |

| Time Investment | Typically takes 2-3 hours over several sessions for full curing. | Reduced curing time, often completed within 1-1.5 hours. |

| Maintenance | Requires regular re-seasoning to prevent rust and maintain non-stick qualities. | Less frequent maintenance needed thanks to improved corrosion resistance from nitriding. |

Longevity and Maintenance After Curing

Traditional woks require regular seasoning to maintain a non-stick surface and prevent rust, which can be time-consuming and less durable over time. Nitrided woks, treated with a nitrogen diffusion process, offer enhanced surface hardness and corrosion resistance, resulting in longer-lasting performance after curing.

Longevity of nitrided woks surpasses that of traditional woks due to their improved resistance to wear and oxidation post-curing. Maintenance for nitrided woks is minimal, often requiring only simple cleaning without the need for frequent re-seasoning. This makes nitrided woks more convenient and cost-effective for long-term use in cooking environments.

Best Practices: Tips for Curing Each Type of Wok

Traditional woks require seasoning with oil and gradual heating to develop a natural non-stick surface essential for curing. Avoid sudden temperature changes to prevent warping and maintain the wok's longevity during the curing process.

Nitrided woks benefit from preheating at moderate temperatures to activate the hardened surface, enhancing rust resistance and durability. Use light oil layers and avoid excessive cooking oils to preserve the nitrided coating and ensure optimal curing results.

Related Important Terms

Oxide patina formation

Traditional woks develop an oxide patina through repeated seasoning and use, enhancing non-stick properties and flavor over time, whereas nitrided woks undergo a controlled nitriding process that creates a harder, corrosion-resistant surface with minimal oxide patina formation. The oxide layer on traditional woks promotes natural curing, while nitrided woks rely on their engineered surface for durability without relying heavily on oxide patina.

Nitride surface hardening

Nitrided woks feature a surface hardened through nitrogen diffusion, enhancing wear resistance and longevity compared to traditional wrought iron woks. This nitriding process creates a dense, corrosion-resistant layer that improves curing uniformity and reduces maintenance requirements.

Micro-seasoning layering

Traditional woks develop micro-seasoning layers through repeated heating and oil polymerization, creating a natural non-stick surface that enhances flavor over time. Nitrided woks feature a hardened surface from nitrogen infusion, which accelerates micro-seasoning formation and improves durability, making them more resistant to corrosion and wear during curing.

Non-stick carbon lattice

Traditional woks feature a carbon lattice that develops a natural non-stick patina over time through seasoning, while nitrided woks utilize a hardened, nitrogen-infused surface to enhance scratch resistance and promote a more durable non-stick effect. The nitriding process modifies the carbon lattice at a molecular level, improving heat retention and reducing food adhesion compared to conventional cast iron or carbon steel woks.

Iron nitride curing

Iron nitride curing on nitrided woks enhances surface hardness and corrosion resistance, resulting in superior non-stick properties compared to traditional wok surfaces. This advanced nitriding process forms a durable iron nitride layer that improves heat retention and promotes even curing of ingredients.

Thermal polymerization (wok-specific)

Traditional woks rely on thermal polymerization through repeated heating and seasoning, forming a natural non-stick patina that enhances flavor and prevents rust. Nitrided woks utilize a thermochemical treatment that creates a hardened, corrosion-resistant surface, optimizing thermal polymerization for faster curing and improved durability.

Steel porosity sealing

Nitrided woks feature a hardened steel surface with reduced porosity, enhancing their ability to seal pores during curing and preventing moisture absorption, unlike traditional woks that retain porous steel surfaces prone to corrosion and reduced durability. The nitriding process fills microscopic steel pores, creating a dense, wear-resistant layer that optimizes heat retention and improves the curing performance by maintaining a consistent, non-reactive surface.

Reactive oil infusion

Traditional wok surfaces absorb reactive oil infusion less effectively, leading to uneven curing and potential contamination with metallic ions. Nitrided woks create a hardened, non-reactive surface that enhances oil bonding, improving the curing process by promoting uniform flavor development and increased durability.

Blue steel molecular retention

Blue steel woks feature superior molecular retention due to their unique nitriding process, enhancing heat distribution and durability compared to traditional wok materials. This nitrided surface improves curing efficiency by maintaining consistent thermal conductivity and resisting corrosion over prolonged use.

Traditional wok vs Nitrided wok for curing. Infographic

cookingdiff.com

cookingdiff.com