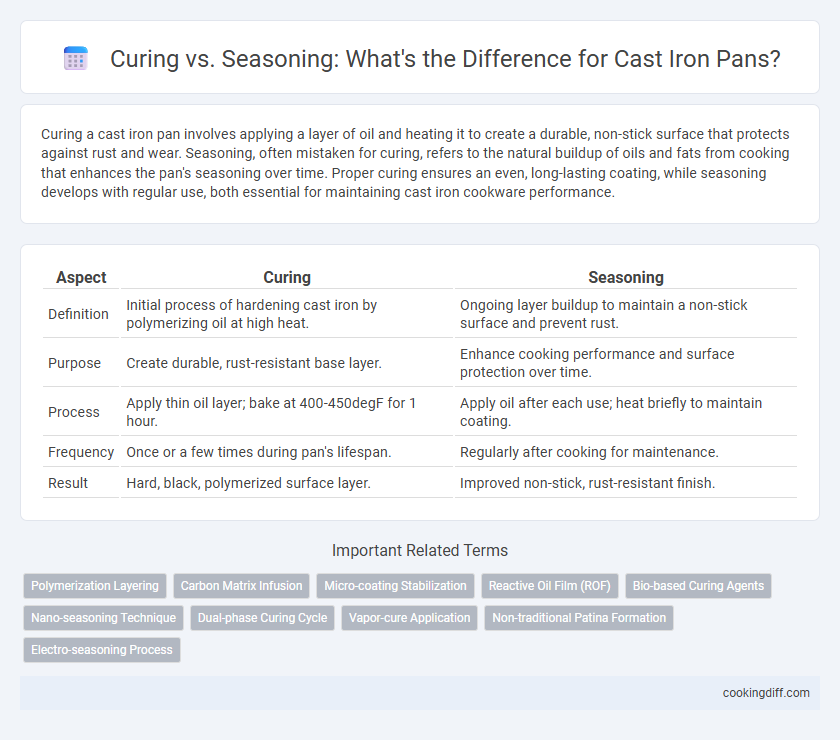

Curing a cast iron pan involves applying a layer of oil and heating it to create a durable, non-stick surface that protects against rust and wear. Seasoning, often mistaken for curing, refers to the natural buildup of oils and fats from cooking that enhances the pan's seasoning over time. Proper curing ensures an even, long-lasting coating, while seasoning develops with regular use, both essential for maintaining cast iron cookware performance.

Table of Comparison

| Aspect | Curing | Seasoning |

|---|---|---|

| Definition | Initial process of hardening cast iron by polymerizing oil at high heat. | Ongoing layer buildup to maintain a non-stick surface and prevent rust. |

| Purpose | Create durable, rust-resistant base layer. | Enhance cooking performance and surface protection over time. |

| Process | Apply thin oil layer; bake at 400-450degF for 1 hour. | Apply oil after each use; heat briefly to maintain coating. |

| Frequency | Once or a few times during pan's lifespan. | Regularly after cooking for maintenance. |

| Result | Hard, black, polymerized surface layer. | Improved non-stick, rust-resistant finish. |

Understanding Curing and Seasoning: Definitions

Curing involves heating the cast iron pan to create a stable oxide layer that protects against rust and enhances durability. Seasoning refers to the process of applying thin layers of oil or fat and baking them to form a non-stick, protective coating. Both curing and seasoning are essential steps to maintain the pan's performance and longevity.

The Science Behind Cast Iron Curing

Curing cast iron involves applying oil and heating it to create a polymerized, non-stick layer, while seasoning builds upon this process by adding repeated layers of oil to enhance durability. The science behind curing relies on the polymerization of fats at high temperatures, which chemically bond to the iron surface and prevent rust.

- Polymerization - Heat causes oil molecules to break down and form a hard, plastic-like coating on the cast iron.

- Oxidation Reaction - Oxygen in the air reacts with oil molecules to create a stable, protective layer on the pan's surface.

- Surface Bonding - The cured layer adheres to microscopic pores in the cast iron, creating a durable non-stick finish.

Purpose of Seasoning Cast Iron Cookware

What is the primary purpose of seasoning cast iron cookware? Seasoning creates a natural, non-stick surface by polymerizing oils onto the pan's surface, which protects it from rust and enhances cooking performance. This layer improves durability and allows for easier cleaning compared to unseasoned cast iron.

Key Differences: Curing vs Seasoning

Curing a cast iron pan involves heating it with oil to create a hard, protective layer that prevents rust and enhances durability. Seasoning refers to the process of building up this layer through repeated applications of oil and heating, which also improves the pan's non-stick properties.

Curing is a one-time, intensive process that forms the initial polymerized coating on the cast iron surface, while seasoning is an ongoing maintenance routine to reinforce and repair this coating. Proper curing establishes a strong base layer, making subsequent seasoning more effective and long-lasting. Without curing, seasoning alone may result in uneven protection and increased risk of rust.

Common Misconceptions Explained

| Misconception | Seasoning and curing cast iron pans are often thought to be interchangeable processes. |

| Clarification | Curing refers to the initial baking of a pan to create a stable surface, while seasoning involves building up multiple layers of polymerized oils to develop a non-stick coating. |

| Key Fact | Proper seasoning enhances durability and rust resistance, whereas curing primarily stabilizes the pan's material before seasoning can take effect. |

Step-by-Step Guide to Curing Cast Iron

Curing a cast iron pan involves heating it with oil to create a protective, non-stick surface, unlike seasoning which is repeated layers for maintenance. Proper curing prevents rust and enhances the pan's durability and cooking performance.

- Clean the pan thoroughly - Remove any factory coating or debris using hot water and mild soap, then dry completely.

- Apply a thin layer of oil - Use a high smoke point oil such as flaxseed or vegetable oil to coat the entire surface, including handles and exterior.

- Bake the pan in the oven - Place it upside down at 450-500degF for about one hour, then allow it to cool inside the oven.

Repeat the curing process several times to build a solid, durable seasoning layer that protects and enhances your cast iron pan.

Best Practices for Seasoning Cast Iron Pans

Seasoning cast iron pans involves applying a thin layer of oil and heating it to create a natural, non-stick coating. This process enhances the pan's durability and prevents rust by polymerizing the oil onto the surface.

Curing refers to the initial baking of the pan to remove moisture and prepare it for seasoning, but seasoning is the ongoing maintenance that builds the protective layer. Best practices for seasoning include using high-smoke point oils like flaxseed or grapeseed oil and baking the pan at 450degF to 500degF for an hour.

Choosing Oils for Curing and Seasoning

Choosing the right oil for curing a cast iron pan is crucial for building a durable, non-stick surface; flaxseed oil and grapeseed oil are popular due to their high smoke points and polymerization properties. These oils create a hard, protective layer that enhances the pan's longevity and cooking performance.

For seasoning, oils like vegetable oil or canola oil are effective because they provide a balanced coating that improves the pan's non-stick qualities with repeated use. Proper application and heating of these oils during seasoning help maintain the pan's smooth surface and prevent rust.

Maintaining Your Cast Iron’s Protective Layer

Maintaining your cast iron's protective layer requires proper curing, which creates a durable, non-stick surface by polymerizing oils through heat. Seasoning helps reinforce this layer by regularly adding thin oil coatings that prevent rust and enhance cooking performance. Consistent curing and seasoning together ensure long-lasting protection and optimal pan durability.

Related Important Terms

Polymerization Layering

Curing a cast iron pan involves heating oil to create a durable polymerized layer that bonds to the pan's surface, providing non-stick properties and rust resistance. Seasoning, often confused with curing, typically refers to the maintenance process of adding thin polymerized layers over time, enhancing the pan's protective coating and improving cooking performance.

Carbon Matrix Infusion

Curing a cast iron pan involves creating a carbon matrix infusion by polymerizing oils at high heat, which bonds to the iron surface and forms a durable, non-stick layer. Seasoning, in contrast, typically refers to the ongoing maintenance of this carbon layer, enhancing the pan's performance and corrosion resistance over time.

Micro-coating Stabilization

Curing a cast iron pan involves polymerizing oil at high heat to create a durable, non-stick micro-coating that stabilizes the pan's surface against rust and wear. Unlike seasoning, which gradually builds layers of protective residue through repeated use, curing chemically bonds the coating for immediate, long-lasting protection and enhanced cooking performance.

Reactive Oil Film (ROF)

Curing a cast iron pan involves creating a Reactive Oil Film (ROF) through polymerization of oils at high heat, which forms a durable, non-stick surface that resists rust and enhances cooking performance. Seasoning, while similar, generally refers to the maintenance of this ROF by regularly applying and heating oil to reinforce the protective layer and prevent deterioration over time.

Bio-based Curing Agents

Bio-based curing agents, such as flaxseed oil or beeswax, create a durable, natural polymer layer on cast iron pans that enhances non-stick properties and prevents rusting more effectively than traditional seasoning methods. These eco-friendly agents penetrate the iron surface, offering longer-lasting protection and improved food release without the need for synthetic chemicals.

Nano-seasoning Technique

Nano-seasoning technique enhances cast iron pans by creating a durable, non-stick surface through atomic-level bonding of seasoning oils, outperforming traditional curing methods that rely on simple polymerization. This advanced process improves resistance to rust and wear while maintaining cooking efficiency and ease of maintenance.

Dual-phase Curing Cycle

Dual-phase curing cycle enhances cast iron pan durability by combining an initial high-temperature oil polymerization with a secondary low-temperature seasoning phase, creating a robust, non-stick surface. This method outperforms traditional seasoning alone by improving adhesion of the oil layer and increasing resistance to rust and wear.

Vapor-cure Application

Vapor-curing cast iron pans involves applying a thin layer of oil heated to its smoke point, creating a durable polymerized coating that enhances non-stick properties and prevents rust more effectively than traditional seasoning methods. This technique uses vaporized oil to evenly bond with the pan's surface, resulting in a smoother finish and longer-lasting protection compared to conventional seasoning applications.

Non-traditional Patina Formation

Curing a cast iron pan involves polymerizing a layer of oil through heat, creating a durable and non-stick surface distinct from traditional seasoning that relies on gradual build-up of carbonized fats. This non-traditional patina formation enhances corrosion resistance and improves cooking performance by bonding oil molecules directly to the metal, contrasting with the porous, multi-layered seasoning that develops over time.

Curing vs Seasoning for Cast Iron Pan Infographic

cookingdiff.com

cookingdiff.com