Choosing between a wire rack and a dehydrator tray for curing affects airflow and moisture control during the drying process. Wire racks allow better air circulation around the product, promoting even curing and reducing the risk of mold, while dehydrator trays often have a solid base with limited airflow, which may lead to uneven drying. For optimal curing, wire racks are preferred due to their superior ventilation and ability to maintain consistent drying conditions.

Table of Comparison

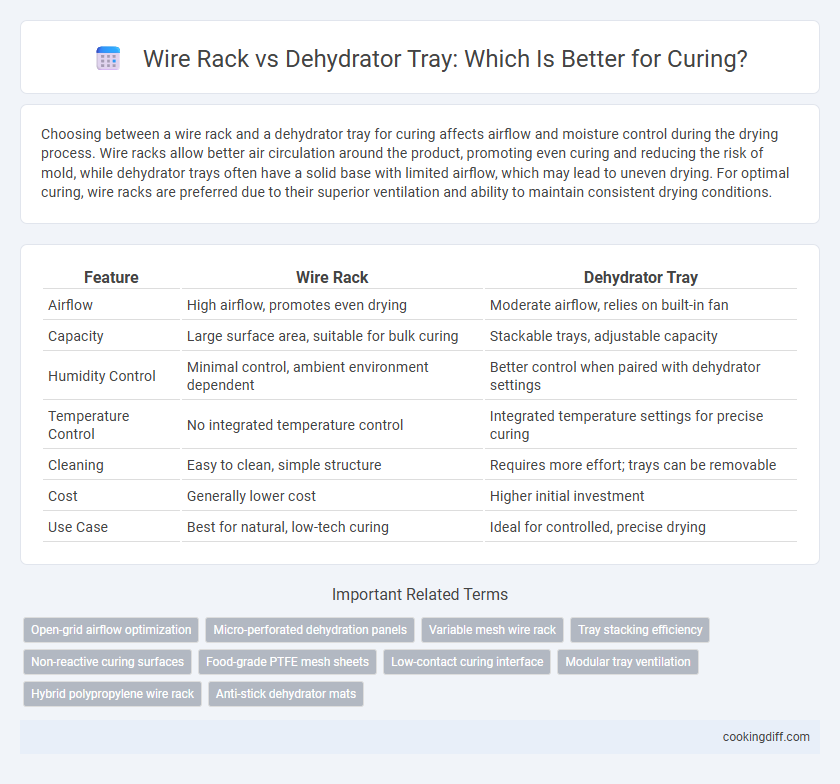

| Feature | Wire Rack | Dehydrator Tray |

|---|---|---|

| Airflow | High airflow, promotes even drying | Moderate airflow, relies on built-in fan |

| Capacity | Large surface area, suitable for bulk curing | Stackable trays, adjustable capacity |

| Humidity Control | Minimal control, ambient environment dependent | Better control when paired with dehydrator settings |

| Temperature Control | No integrated temperature control | Integrated temperature settings for precise curing |

| Cleaning | Easy to clean, simple structure | Requires more effort; trays can be removable |

| Cost | Generally lower cost | Higher initial investment |

| Use Case | Best for natural, low-tech curing | Ideal for controlled, precise drying |

Introduction to Curing: Wire Rack vs Dehydrator Tray

Which method provides better airflow for curing: wire racks or dehydrator trays? Wire racks offer superior ventilation by allowing air to circulate freely around the product, reducing moisture buildup and speeding up the curing process. Dehydrator trays, while designed to stack efficiently, can limit airflow and may require rotation to ensure even curing.

Key Differences Between Wire Racks and Dehydrator Trays

Wire racks and dehydrator trays serve different purposes in the curing process, primarily affecting airflow and moisture control. Wire racks offer open-air circulation while dehydrator trays provide controlled temperature and humidity settings for consistent drying.

- Airflow - Wire racks allow maximum air circulation around the product, enhancing natural drying.

- Temperature Control - Dehydrator trays maintain precise temperature, preventing over-drying or under-curing.

- Moisture Management - Wire racks rely on ambient conditions, whereas dehydrator trays optimize humidity for uniform moisture removal.

Choosing between wire racks and dehydrator trays depends on the desired level of control and consistency in the curing environment.

Surface Area and Airflow: Impact on Curing Efficiency

Wire racks offer increased airflow due to their open grid design, promoting even drying by allowing air to circulate around the product. This enhanced surface area exposure accelerates moisture evaporation, improving curing efficiency compared to solid dehydrator trays.

Dehydrator trays often have less airflow because their solid or perforated surfaces limit air circulation, which can cause uneven curing and longer drying times. Selecting a wire rack maximizes airflow and surface contact, critical factors for optimal and consistent curing results.

Material Durability and Maintenance

Wire racks, typically made from stainless steel, offer superior durability and resistance to rust, making them ideal for long-term use in curing processes. They require minimal maintenance, as their open grid design allows for easy cleaning and airflow, preventing mold buildup.

Dehydrator trays are usually constructed from lightweight plastic or silicone, which may wear down or warp over extended use and high temperatures. These trays demand more frequent cleaning to avoid residue buildup and can be less durable compared to metal wire racks in rigorous curing environments.

Food Safety Considerations in Curing

Wire racks promote better air circulation during the curing process, reducing the risk of bacterial growth by allowing moisture to evaporate more efficiently. Dehydrator trays, while convenient, may trap moisture, increasing the potential for uneven drying and contamination.

Food safety considerations favor wire racks for curing meats and other perishables due to their open design facilitating consistent airflow. Dehydrator trays often require careful monitoring to prevent mold development and spoilage caused by retained humidity. Proper sanitation of both wire racks and dehydrator trays is essential to minimize contamination risks during curing.

Suitability for Various Foods: Meat, Fish, Vegetables

Wire racks offer superior airflow and are ideal for curing meats and fish, promoting even drying and preventing moisture buildup. Dehydrator trays, with their enclosed design, work well for vegetables and fruits, providing consistent heat distribution and preventing small pieces from falling through. Choosing between wire racks and dehydrator trays depends on the food type and desired curing environment to achieve optimal texture and flavor.

Cost Comparison: Wire Rack vs Dehydrator Tray

Wire racks generally offer a more budget-friendly option for curing due to their simple design and widespread availability. Dehydrator trays tend to be pricier but provide enhanced airflow and uniform drying, which can improve curing efficiency.

- Lower Initial Cost - Wire racks are typically less expensive to purchase upfront compared to specialized dehydrator trays.

- Durability and Replacement - Wire racks often require less frequent replacement, contributing to long-term cost savings.

- Efficiency vs. Expense - Dehydrator trays may justify their higher cost by reducing curing time and improving product consistency.

Ease of Use and Setup

Wire racks provide a simple, stackable surface that allows for good airflow during curing, making setup quick and straightforward. Dehydrator trays often require more complex assembly and careful arrangement to ensure even curing but can offer better control over the drying environment.

- Wire racks are easy to use - Their open design allows for easy placement and removal of items without extra adjustments.

- Dehydrator trays need precise setup - Trays must be securely placed in the dehydrator, sometimes requiring calibration for optimal airflow.

- Wire racks require minimal maintenance - They can be cleaned and stored efficiently without specialized parts or settings.

Cleaning and Storage Requirements

| Wire Rack Cleaning and Storage | Wire racks require thorough scrubbing to remove resin and debris, often involving soaking and brushing to maintain hygiene and airflow. They are bulky to store due to their rigid frames, necessitating ample storage space to avoid bending or damage. |

| Dehydrator Tray Cleaning and Storage | Dehydrator trays are generally dishwasher-safe, making cleaning more convenient and efficient with less manual effort. Their stackable, flat design allows for compact storage, conserving space and protecting trays from warping. |

Related Important Terms

Open-grid airflow optimization

Wire racks provide superior open-grid airflow, allowing maximum air circulation around items during curing, which helps prevent moisture buildup and promotes even drying. Dehydrator trays typically have smaller perforations that restrict airflow, making them less efficient for curing processes that require optimal ventilation.

Micro-perforated dehydration panels

Micro-perforated dehydration panels on dehydrator trays facilitate superior airflow and even moisture removal compared to traditional wire racks, promoting consistent curing and reducing the risk of mold. These panels' design optimizes dehydration efficiency by allowing precise humidity control, essential for preserving product quality during the curing process.

Variable mesh wire rack

Variable mesh wire racks enhance airflow during curing by allowing consistent humidity and temperature distribution around items, leading to more uniform drying compared to standard dehydrator trays. Their adjustable mesh sizes prevent small pieces from falling through while maximizing ventilation, making them ideal for curing herbs, meats, and other delicate products.

Tray stacking efficiency

Wire racks offer superior airflow due to their open-grid design, promoting even drying and reducing curing time in stacked arrangements. Dehydrator trays, typically solid with perforations, limit airflow when stacked, making wire racks more efficient for curing processes requiring multiple layers.

Non-reactive curing surfaces

Wire racks and dehydrator trays both offer non-reactive curing surfaces essential for preserving flavor and preventing chemical reactions during the curing process. Wire racks provide superior air circulation, accelerating moisture removal, while dehydrator trays ensure uniform drying with controlled airflow in enclosed environments.

Food-grade PTFE mesh sheets

Food-grade PTFE mesh sheets on dehydrator trays provide superior airflow and non-stick properties essential for even curing, unlike wire racks that may cause uneven drying due to inconsistent air circulation and potential contamination risks. PTFE mesh's chemical resistance and easy cleaning make it the optimal surface for curing delicate products, ensuring product quality and preventing residue buildup.

Low-contact curing interface

Wire racks provide a low-contact curing interface by allowing maximum air circulation around the product, reducing moisture buildup and promoting even drying. Dehydrator trays, often solid or with minimal perforations, can limit airflow and increase surface contact, potentially slowing the curing process and affecting consistency.

Modular tray ventilation

Wire racks provide superior airflow with open-grid designs that promote even curing by minimizing moisture buildup. Modular dehydrator trays often feature adjustable ventilation slats, allowing customized airflow control to optimize drying conditions for different materials.

Hybrid polypropylene wire rack

Hybrid polypropylene wire racks offer superior airflow and moisture control compared to traditional dehydrator trays, enhancing the curing process by promoting even drying and reducing mold risk. Their durable, non-stick surface resists warping and facilitates easy cleaning, making them ideal for long-term curing applications.

Wire rack vs dehydrator tray for curing. Infographic

cookingdiff.com

cookingdiff.com