Traditional smokehouses provide even, deep smoke penetration ideal for curing larger cuts of meat, enhancing flavor and preservation through controlled heat and smoke exposure. Cold smoker tubes offer a compact, smoke-only approach that maintains low temperatures, preserving the meat's texture and freshness while infusing subtle smoky aromas. Choosing between the two depends on the desired intensity of smoke flavor and the curing environment.

Table of Comparison

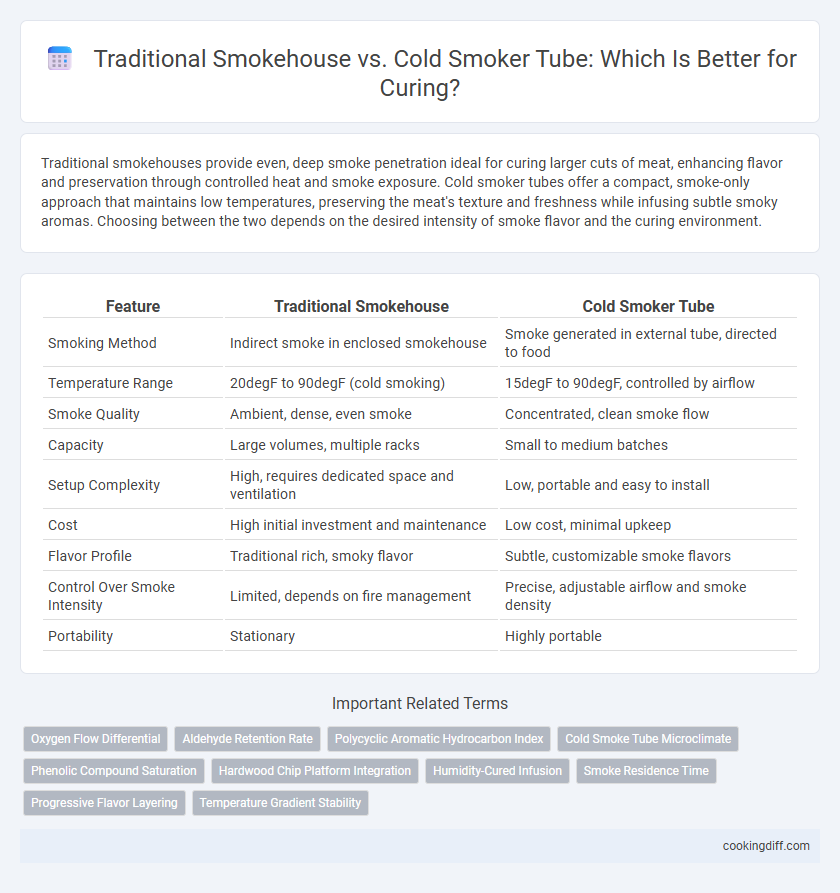

| Feature | Traditional Smokehouse | Cold Smoker Tube |

|---|---|---|

| Smoking Method | Indirect smoke in enclosed smokehouse | Smoke generated in external tube, directed to food |

| Temperature Range | 20degF to 90degF (cold smoking) | 15degF to 90degF, controlled by airflow |

| Smoke Quality | Ambient, dense, even smoke | Concentrated, clean smoke flow |

| Capacity | Large volumes, multiple racks | Small to medium batches |

| Setup Complexity | High, requires dedicated space and ventilation | Low, portable and easy to install |

| Cost | High initial investment and maintenance | Low cost, minimal upkeep |

| Flavor Profile | Traditional rich, smoky flavor | Subtle, customizable smoke flavors |

| Control Over Smoke Intensity | Limited, depends on fire management | Precise, adjustable airflow and smoke density |

| Portability | Stationary | Highly portable |

Introduction to Curing: Tradition Meets Innovation

| Traditional smokehouses offer time-honored methods of curing meat, relying on slow smoking over wood fires that impart rich, complex flavors and natural preservation. Cold smoker tubes enable precise temperature control and consistent smoke exposure, preserving the texture and enhancing flavor complexity without cooking the meat. Combining traditional techniques with modern cold smoking technology optimizes curing efficiency while maintaining authentic taste profiles. |

What is a Traditional Smokehouse?

A traditional smokehouse is a structure designed for smoking and curing meats using controlled heat and wood smoke over extended periods. It maintains consistent temperatures and smoke levels to enhance flavor and preserve the food.

- Wood-Fueled Structure - Uses hardwoods like hickory or oak to generate smoke, imparting distinct flavors.

- Temperature Control - Maintains a steady temperature, typically between 165degF and 225degF, crucial for proper curing.

- Capacity - Large enough to smoke multiple cuts of meat simultaneously, suited for batch processing.

The traditional smokehouse offers a time-honored method that balances smoke intensity and heat for optimal curing results.

Understanding the Cold Smoker Tube Method

The cold smoker tube method offers a controlled way to infuse smoke flavor without raising the temperature above 90degF, preserving the texture and moisture of the cured meat. Unlike traditional smokehouses that use large chambers and sometimes higher temperatures, cold smoker tubes generate smoke in a compact, portable design ideal for precise curing processes.

- Temperature Control - Cold smoker tubes maintain low temperatures essential for cold smoking, preventing cooking while allowing smoke absorption.

- Portability - The compact size makes cold smoker tubes easy to use in various environments compared to bulky traditional smokehouses.

- Smoke Density - Cold smoker tubes produce consistent, dense smoke, resulting in enhanced flavor penetration during curing.

Flavor Development: Smokehouse vs Cold Smoker Tube

Traditional smokehouses impart deep, robust smoky flavors through prolonged exposure to controlled heat and hardwood smoke, enhancing the complexity of cured meats. The process combines both heat and smoke, accelerating flavor absorption and tenderization.

Cold smoker tubes produce delicate, subtle smoky notes at lower temperatures, preserving the meat's original texture and moisture content. This method is ideal for gentle smoke infusion without cooking, allowing for nuanced flavor layering during long curing periods.

Temperature Control in Curing Processes

How does temperature control differ between a traditional smokehouse and a cold smoker tube during curing? Traditional smokehouses often experience temperature fluctuations due to larger volume and external environmental factors, making consistent temperature control challenging. Cold smoker tubes maintain lower, more stable temperatures ideal for curing, typically ranging between 68degF to 86degF (20degC to 30degC), which prevents meat from cooking while enhancing smoke penetration.

Equipment and Space Requirements

Traditional smokehouses require substantial space and robust construction to maintain consistent temperatures and smoke levels, often involving brick or wood structures. These setups demand specialized ventilation systems and generate significant smoke output, making them suitable for larger-scale or outdoor curing operations.

Cold smoker tubes are compact, portable devices ideal for small-scale curing projects and indoor use, producing smoke at low temperatures to preserve delicate flavors. Their minimal space requirements and ease of integration into existing kitchens or curing environments provide efficient smoke generation without extensive infrastructure.

Time Investment: Traditional vs Modern Methods

Traditional smokehouses require a significant time investment, often needing several hours to days to properly cure meat through slow smoking processes. In contrast, cold smoker tubes offer a more controlled environment, reducing curing time by maintaining consistent temperatures and smoke levels.

Using a traditional smokehouse demands frequent monitoring and manual adjustments, which can extend the overall curing timeline. Cold smoker tubes streamline the process with easier temperature regulation and less hands-on involvement, making them ideal for quicker curing cycles. This modern method balances efficiency with flavor infusion, shortening the time required without compromising quality.

Food Safety Considerations

Traditional smokehouses expose meat to smoke and heat, which can raise the temperature enough to kill harmful bacteria, enhancing food safety during curing. Cold smoker tubes operate at lower temperatures, typically below 90degF (32degC), which limits bacterial kill and requires stringent control of meat refrigeration before and after smoking. Proper curing techniques, including salt concentration and drying, are essential in both methods to prevent pathogen growth and ensure safe consumption.

Cost Comparison: Smokehouse vs Cold Smoker Tube

Traditional smokehouses typically demand a higher initial investment due to construction materials and space requirements, often costing several thousand dollars. Cold smoker tubes offer a more affordable alternative, with prices usually ranging from $50 to $200, making them accessible for small-scale or hobbyist curing. Operating costs for cold smoker tubes are generally lower as they consume less fuel and require minimal maintenance compared to the larger smokehouse setup.

Related Important Terms

Oxygen Flow Differential

Traditional smokehouses expose meat to an open environment where oxygen flow varies naturally, influencing the curing process through uneven smoke penetration and surface drying. In contrast, cold smoker tubes regulate oxygen flow precisely, ensuring consistent smoke density and controlled curing conditions that enhance flavor development and preservation.

Aldehyde Retention Rate

Traditional smokehouses produce a lower aldehyde retention rate due to longer exposure to high heat and open flame, causing greater aldehyde volatilization. Cold smoker tubes maintain higher aldehyde retention by using indirect, low-temperature smoke generation, preserving more flavor compounds during the curing process.

Polycyclic Aromatic Hydrocarbon Index

Traditional smokehouses commonly produce higher Polycyclic Aromatic Hydrocarbon (PAH) levels due to prolonged exposure to smoke and incomplete combustion of organic materials. Cold smoker tubes, by contrast, significantly reduce PAH formation by maintaining lower temperatures and controlling smoke flow, enhancing food safety during curing.

Cold Smoke Tube Microclimate

Cold smoke tubes create a controlled microclimate by maintaining low temperatures and consistent smoke flow, essential for preserving delicate flavors and preventing spoilage during curing. Traditional smokehouses often lack precise temperature control, which can lead to uneven curing and a higher risk of bacterial growth compared to the stable environment provided by cold smoke tubes.

Phenolic Compound Saturation

Traditional smokehouses produce higher phenolic compound saturation due to prolonged exposure to open wood smoke, enhancing flavor and antimicrobial properties during curing. Cold smoker tubes generate lower phenolic levels by controlling smoke temperature and density, resulting in milder flavor profiles and reduced surface saturation.

Hardwood Chip Platform Integration

Traditional smokehouses utilize hardwood chips directly on hot coals to infuse meats with deep, rich flavors, relying on high temperatures to cure and preserve. Cold smoker tubes integrate hardwood chip platforms designed for low-temperature smoke generation, enabling precise flavor control without cooking, ideal for delicate curing processes.

Humidity-Cured Infusion

Traditional smokehouses provide natural humidity control essential for curing, allowing smoke to penetrate meat fibers deeply during the humidity-cured infusion process. Cold smoker tubes, while offering precise temperature regulation, often require additional humidity management to achieve the same level of infused moisture and flavor complexity.

Smoke Residence Time

Traditional smokehouses provide extended smoke residence time with slow, consistent exposure that allows deep flavor penetration and enhanced curing, while cold smoker tubes offer shorter smoke exposure, ideal for delicate curing processes that require precise temperature control and minimal heat impact. Smoke residence time in traditional smokehouses ranges from several hours to days, significantly impacting product texture and flavor intensity compared to the brief, controlled smoking cycles of cold smoker tubes.

Progressive Flavor Layering

Traditional smokehouses infuse meat with intense, deep flavors through prolonged exposure to smoke and controlled heat, creating complex, multi-dimensional profiles. Cold smoker tubes offer precise, low-temperature smoke application that gradually builds subtle, layered flavors without cooking the meat, allowing for a more delicate and nuanced taste development.

Traditional smokehouse vs cold smoker tube for curing. Infographic

cookingdiff.com

cookingdiff.com