Wet curing involves soaking or injecting meat with a brine solution to evenly distribute salt and flavors, resulting in a moist and tender charcuterie product. Koji curing uses the enzyme-rich mold Aspergillus oryzae to break down proteins and fats, enhancing umami and developing complex, savory flavors without added salt. While wet curing emphasizes moisture retention and preservation, koji curing focuses on enzymatic fermentation for depth of flavor and unique texture profiles.

Table of Comparison

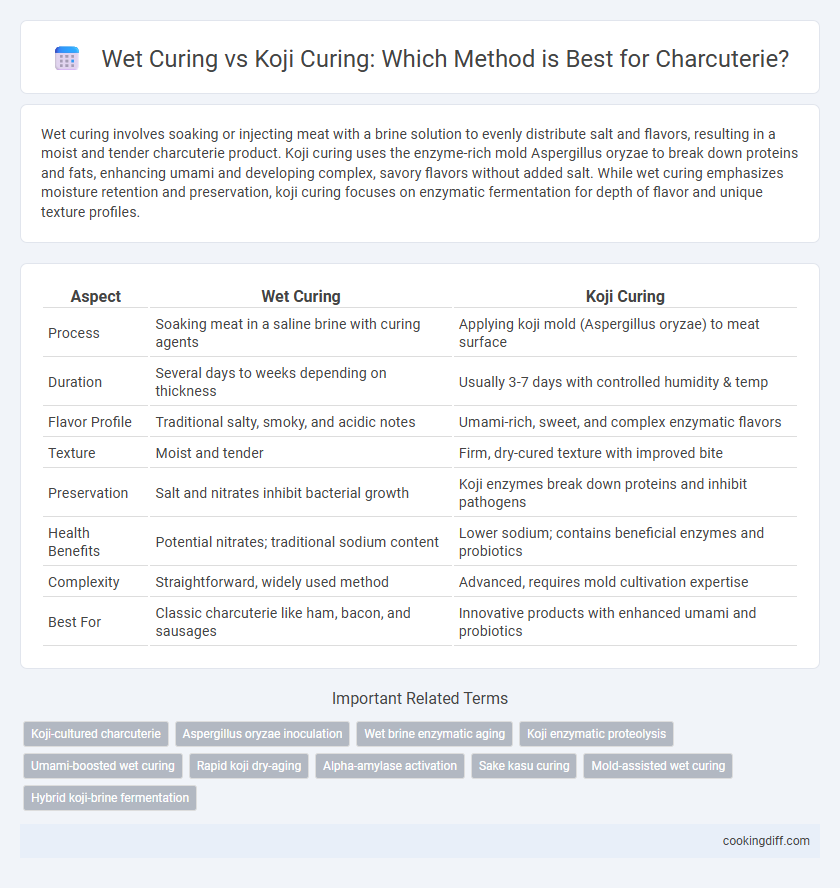

| Aspect | Wet Curing | Koji Curing |

|---|---|---|

| Process | Soaking meat in a saline brine with curing agents | Applying koji mold (Aspergillus oryzae) to meat surface |

| Duration | Several days to weeks depending on thickness | Usually 3-7 days with controlled humidity & temp |

| Flavor Profile | Traditional salty, smoky, and acidic notes | Umami-rich, sweet, and complex enzymatic flavors |

| Texture | Moist and tender | Firm, dry-cured texture with improved bite |

| Preservation | Salt and nitrates inhibit bacterial growth | Koji enzymes break down proteins and inhibit pathogens |

| Health Benefits | Potential nitrates; traditional sodium content | Lower sodium; contains beneficial enzymes and probiotics |

| Complexity | Straightforward, widely used method | Advanced, requires mold cultivation expertise |

| Best For | Classic charcuterie like ham, bacon, and sausages | Innovative products with enhanced umami and probiotics |

Introduction to Wet Curing and Koji Curing

Wet curing involves submerging meat in a brine solution to enhance flavor and preservation, while koji curing uses a mold culture to enzymatically tenderize and ferment the meat. Both methods offer distinct approaches to developing texture and taste in charcuterie products.

- Wet curing - Utilizes saltwater brine that penetrates the meat, promoting moisture retention and flavor infusion.

- Koji curing - Employs Aspergillus oryzae mold to break down proteins and fats, creating complex umami flavors.

- Application difference - Wet curing is traditional for producing moist, well-preserved meats, whereas koji curing adds unique enzymatic fermentation benefits.

The Science Behind Wet Curing

Wet curing involves immersing meat in a saline solution that facilitates salt diffusion and flavor penetration through osmosis. This method enhances microbial control by creating an environment unsuitable for spoilage bacteria, ensuring meat preservation.

- Osmosis and Diffusion - Salt molecules move from the curing solution into the meat cells, drawing out moisture and creating a dry environment unfavorable to bacteria.

- Microbial Inhibition - The high salt concentration in wet curing inhibits the growth of pathogens and spoilage organisms by reducing water activity.

- Flavor Development - Wet curing allows uniform distribution of seasoning and curing agents, contributing to consistent flavor throughout the charcuterie product.

Understanding Koji Curing in Charcuterie

Koji curing in charcuterie uses the mold Aspergillus oryzae to enzymatically break down proteins and fats, enhancing flavor complexity and umami. Unlike traditional wet curing, koji curing accelerates fermentation without relying on excessive salt or nitrates, promoting a cleaner and more nuanced taste. This method also improves texture by tenderizing meat while developing unique aromatic profiles intrinsic to Japanese culinary techniques.

Flavor Development: Wet Curing vs Koji Curing

Wet curing infuses charcuterie with a salty, savory flavor by immersing the meat in a brine solution, promoting moisture retention and a subtle tang. Koji curing employs Aspergillus oryzae mold to break down proteins and fats, creating complex umami-rich and slightly sweet notes unique to fermented Asian cuisine.

Wet curing typically results in a more straightforward, briny taste profile with enhanced juiciness, ideal for traditional European charcuterie such as ham and bacon. Koji curing accelerates enzymatic reactions, enhancing tenderness and imparting depth through natural fermentation, which intensifies flavor complexity beyond conventional methods. This process can yield a richer aromatic experience with earthy and nutty undertones that evolve during aging.

Texture Differences in Cured Meats

Wet curing infuses moisture into charcuterie, resulting in a tender, juicy texture that enhances the meat's natural succulence. Koji curing employs enzymes from Aspergillus oryzae to break down proteins and fats, producing a firmer, more complex mouthfeel with subtle umami notes. Texture differences are significant, as wet curing maintains softness while koji curing creates a denser, slightly drier consistency favored in artisanal preparations.

Safety Considerations for Each Method

Wet curing relies on brine solutions that inhibit harmful bacterial growth through high salt concentration, but improper temperature control can lead to unsafe microbial activity. Koji curing uses mold cultures like Aspergillus oryzae, requiring stringent hygiene to prevent unwanted pathogens and ensure safe fermentation.

- Temperature Control - Maintaining temperatures below 10degC during wet curing slows pathogen proliferation effectively.

- Moisture Levels - Excess moisture in wet curing can promote Listeria monocytogenes growth if sanitation is inadequate.

- Koji Strain Purity - Using high-quality Aspergillus oryzae strains reduces risk of mycotoxin-producing molds during koji curing.

Understanding these safety parameters is crucial to producing high-quality, pathogen-free charcuterie with either curing technique.

Ingredient Requirements and Preparation Steps

Wet curing requires a precise brine solution typically composed of water, salt, sugar, and curing agents such as sodium nitrite, which must be thoroughly prepared and refrigerated to ensure safety and flavor consistency. Koji curing utilizes Aspergillus oryzae mold inoculated onto rice or barley, necessitating a controlled fermentation environment with specific temperature and humidity to promote enzymatic activity.

Preparation steps for wet curing involve fully submerging the meat in the brine for several days to weeks depending on size and recipe, followed by drying before aging or cooking. Koji curing starts with inoculating the protein surface with koji spores, allowing fermentation at around 30degC for a set period, then drying and aging to develop umami flavors unique to this method.

Timeframes: Curing Duration Comparison

Wet curing typically involves immersing meat in a brine solution, accelerating the curing process with durations ranging from a few days to 2 weeks depending on the product size. Koji curing, using Aspergillus oryzae mold, requires longer timeframes, often extending from 3 weeks to several months to develop complex umami flavors and proper texture.

Wet curing's shorter curing duration suits quick production cycles, especially for meats like ham and bacon, where moisture retention is critical. In contrast, koji curing enhances enzymatic breakdown over extended periods, ideal for artisanal charcuterie emphasizing flavor depth and tenderness.

Application Suitability for Popular Meats

Which curing method is better suited for popular meats in charcuterie? Wet curing is ideal for pork cuts like hams and bacon, offering deep moisture penetration and balanced salt distribution. Koji curing excels with leaner meats such as beef or game, enhancing umami flavors through enzymatic fermentation without adding excess moisture.

Related Important Terms

Koji-cultured charcuterie

Koji-cultured charcuterie utilizes Aspergillus oryzae enzymes to accelerate protein breakdown and enhance umami flavors, creating a distinct savory profile compared to traditional wet curing methods. This fermentation technique improves texture and aroma while reducing curing time, offering a more complex and nuanced taste experience.

Aspergillus oryzae inoculation

Wet curing relies on brine solutions to preserve meats, while koji curing utilizes Aspergillus oryzae inoculation to enhance flavor and texture through enzymatic breakdown of proteins and fats. The application of Aspergillus oryzae in koji curing promotes umami development and natural fermentation, differentiating it from traditional wet curing methods.

Wet brine enzymatic aging

Wet curing using brine facilitates enzymatic aging by maintaining moisture and promoting uniform salt diffusion, enhancing flavor development and tenderness in charcuterie. Koji curing introduces specific molds that produce unique umami compounds, but wet brine enzymatic aging remains superior for consistent texture and milder, balanced taste profiles.

Koji enzymatic proteolysis

Koji curing utilizes Aspergillus oryzae enzymes to induce proteolysis, breaking down proteins into flavorful peptides and amino acids, enhancing umami and tenderness in charcuterie. Wet curing relies on salt and brine to preserve meat primarily through osmotic dehydration and microbial inhibition, lacking the enzymatic complexity provided by koji's proteolytic activity.

Umami-boosted wet curing

Wet curing enhances charcuterie's umami profile through saltwater brines infused with natural flavor enhancers like kombu or shiitake, accelerating protein breakdown and glutamate release. Koji curing relies on mold fermentation for enzymatic transformations, but wet curing's direct infusion maximizes immediate umami intensity and moisture retention.

Rapid koji dry-aging

Rapid koji dry-aging in charcuterie utilizes Aspergillus oryzae enzymes to accelerate protein breakdown and flavor development, offering a faster and more complex curing process compared to traditional wet curing methods that rely on brine or direct salt application. This technique enhances umami characteristics and tenderness while reducing moisture content, resulting in distinct artisanal textures and richer savory profiles prized in modern dry-aged meats.

Alpha-amylase activation

Wet curing relies on salt and moisture to preserve meat, but koji curing uniquely activates alpha-amylase enzymes through Aspergillus oryzae mold, breaking down starches and enhancing flavor and texture in charcuterie. This enzymatic activity in koji curing accelerates tenderization and develops complex umami profiles not achievable through traditional wet curing methods.

Sake kasu curing

Sake kasu curing utilizes the nutrient-rich lees from sake production to impart a subtle sweetness and umami depth, enhancing the flavor profile of charcuterie compared to traditional wet curing, which relies on brine solutions for moisture retention and preservation. The enzymatic activity in sake kasu accelerates protein breakdown, resulting in a tender texture and complex aroma that differentiates it from koji curing, where Aspergillus oryzae molds primarily drive fermentation processes.

Mold-assisted wet curing

Mold-assisted wet curing enhances charcuterie by promoting specific beneficial molds that inhibit spoilage bacteria and develop complex flavors through enzymatic activity. This technique offers a controlled environment with high humidity, accelerating fermentation while preserving meat texture and ensuring food safety compared to traditional koji curing methods.

Wet curing vs koji curing for charcuterie. Infographic

cookingdiff.com

cookingdiff.com