Soapstone griddles provide superior heat retention and even heating, making them ideal for curing meats or fish as they prevent hot spots that can cause uneven curing. Ceramic-coated griddles offer a non-stick surface that is easier to clean and resistant to acidic marinades, but they may not distribute heat as evenly as soapstone. Choosing between the two depends on whether consistent heat or ease of maintenance is the priority in the curing process.

Table of Comparison

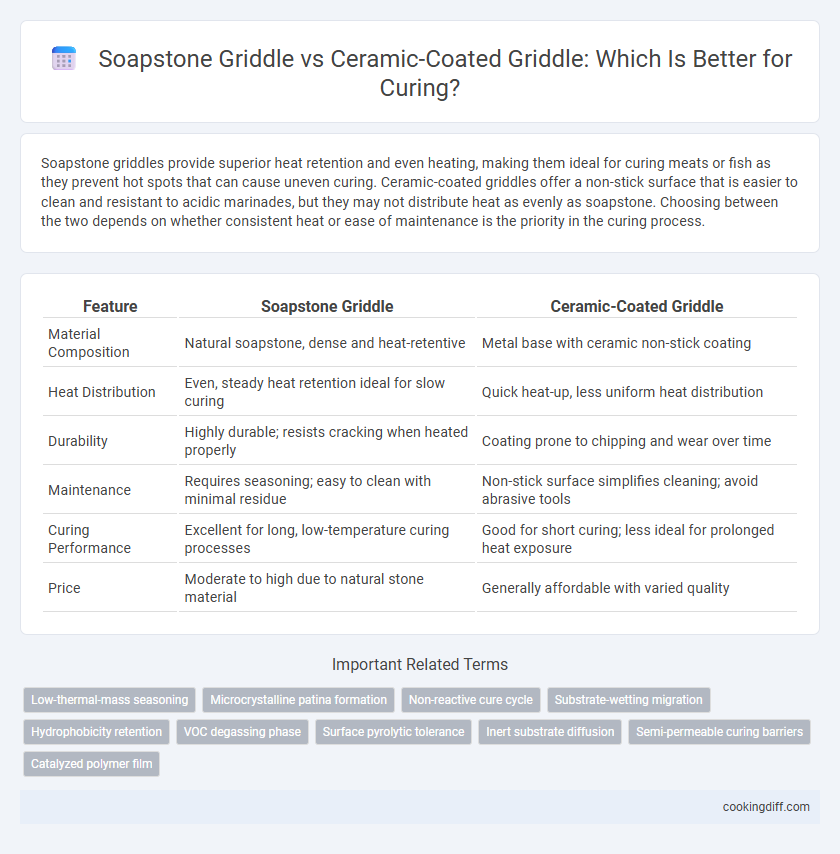

| Feature | Soapstone Griddle | Ceramic-Coated Griddle |

|---|---|---|

| Material Composition | Natural soapstone, dense and heat-retentive | Metal base with ceramic non-stick coating |

| Heat Distribution | Even, steady heat retention ideal for slow curing | Quick heat-up, less uniform heat distribution |

| Durability | Highly durable; resists cracking when heated properly | Coating prone to chipping and wear over time |

| Maintenance | Requires seasoning; easy to clean with minimal residue | Non-stick surface simplifies cleaning; avoid abrasive tools |

| Curing Performance | Excellent for long, low-temperature curing processes | Good for short curing; less ideal for prolonged heat exposure |

| Price | Moderate to high due to natural stone material | Generally affordable with varied quality |

Introduction to Curing with Griddles

Curing a griddle involves seasoning its surface to create a non-stick, rust-resistant layer that enhances cooking performance. Soapstone griddles naturally possess excellent heat retention and require minimal curing compared to ceramic-coated griddles, which depend heavily on proper seasoning to maintain their coating integrity.

Soapstone's dense structure ensures even heat distribution, making it ideal for slow curing processes that build a durable cooking surface. Ceramic-coated griddles demand careful curing to prevent chipping and to extend the lifespan of the coating while providing a smooth, easy-to-clean surface.

Overview: Soapstone Griddle vs Ceramic-Coated Griddle

Soapstone griddles offer excellent heat retention and even heat distribution, making them ideal for curing processes that require consistent temperatures. Ceramic-coated griddles provide a non-stick surface that simplifies cleaning but may not retain heat as evenly as soapstone. Choosing between them depends on whether heat consistency or maintenance ease is prioritized during curing.

Heat Retention for Effective Curing

Soapstone griddles offer superior heat retention due to their dense, natural composition, ensuring consistent and even temperature maintenance essential for effective curing. Ceramic-coated griddles provide a non-stick surface but typically have lower heat retention, which may require more frequent temperature adjustments during the curing process. Optimizing heat retention in soapstone griddles enhances flavor development and texture by maintaining steady curing conditions over extended periods.

Surface Reactivity and Flavor Impact

Soapstone griddles offer low surface reactivity, ensuring that natural flavors of the food remain unaltered during curing. Ceramic-coated griddles exhibit higher surface reactivity, which can introduce subtle flavor changes that may enhance or interfere with the curing process depending on the recipe.

Soapstone's inert surface provides a consistent curing environment by evenly distributing heat without chemical interaction, preserving the purity of flavors. In contrast, ceramic-coated griddles may react with acidic or alkaline ingredients, potentially affecting the taste and texture of cured food. Understanding these differences is crucial for achieving desired flavor profiles during prolonged curing sessions.

Moisture Management During Curing

How does moisture management during curing differ between soapstone griddles and ceramic-coated griddles? Soapstone griddles retain heat evenly, promoting consistent moisture evaporation and preventing sogginess in cured foods. Ceramic-coated griddles offer a non-porous surface that resists moisture absorption but may cause uneven drying due to less heat retention.

Durability and Longevity in Curing Processes

| Soapstone griddle | Offers exceptional durability due to its dense, non-porous nature that withstands repeated heating and cooling cycles without cracking. Its natural composition retains heat evenly, ensuring consistent curing temperatures and extending the lifespan of the griddle over years of use. Resistant to scratches and chemical corrosion, soapstone griddles maintain their structural integrity and surface quality during intensive curing processes. |

| Ceramic-coated griddle | Features a sleek, non-stick surface that resists heat effectively but is prone to chipping and wear over extended curing use. The ceramic coating can degrade with repeated thermal cycling and abrasive cleaning, reducing longevity compared to soapstone. While initially durable, ceramic-coated griddles require careful handling to preserve the coating's integrity and maintain optimal curing performance. |

Cleaning and Maintenance After Curing

Soapstone griddles offer natural non-porous surfaces that resist staining and absorb fewer odors, simplifying cleaning after curing. Their durability allows for easy scrubbing without risking surface damage, making maintenance straightforward.

Ceramic-coated griddles require gentle cleaning to avoid chipping the smooth, non-stick surface, which can degrade if abrasive tools are used. Proper upkeep involves mild detergents and soft sponges to maintain the coating's integrity and performance post-curing.

Safety Considerations for Curing on Griddles

Soapstone griddles offer natural heat retention and an inert surface ideal for safe curing without chemical interference. Ceramic-coated griddles provide a non-stick surface that resists high temperatures but may degrade with abrasive curing methods.

- Non-Toxic Surface - Soapstone is naturally non-porous and free from harmful coatings, ensuring no toxic fumes during curing.

- Durability Concerns - Ceramic coatings can crack or chip under thermal stress, potentially releasing particles into the food.

- Heat Retention - Soapstone maintains steady heat, reducing the risk of burning or uneven curing compared to ceramic alternatives.

Cost Comparison: Soapstone vs Ceramic-Coated Griddles

Soapstone griddles generally have a higher upfront cost compared to ceramic-coated griddles due to their dense, natural stone composition. Ceramic-coated griddles are more affordable initially but may require replacement sooner because of coating wear and potential chipping.

- Initial Investment - Soapstone griddles cost between $80 and $150, while ceramic-coated options range from $40 to $90.

- Durability Impact - Soapstone's longevity reduces long-term expenses despite the higher purchase price.

- Maintenance Costs - Ceramic coatings may necessitate more frequent replacement or re-coating, increasing overall costs over time.

Related Important Terms

Low-thermal-mass seasoning

Soapstone griddles offer a low-thermal-mass surface that heats evenly and cools quickly, enhancing the curing process by allowing precise temperature control during seasoning. Ceramic-coated griddles retain heat longer due to higher thermal mass, which can lead to uneven seasoning and longer curing times.

Microcrystalline patina formation

Soapstone griddles promote superior microcrystalline patina formation due to their dense, natural mineral composition that enhances seasoning and durability during curing. Ceramic-coated griddles, while resistant to rust and easier to clean, may inhibit optimal microcrystalline patina development because their synthetic surface lacks the porous texture essential for deep oil absorption and seasoning buildup.

Non-reactive cure cycle

Soapstone griddles provide a superior non-reactive cure cycle for food items, maintaining consistent heat distribution without altering flavors or chemical composition during curing. Ceramic-coated griddles, while offering a smoother surface, may occasionally interact with acidic ingredients, potentially affecting the non-reactive curing process and final taste.

Substrate-wetting migration

Soapstone griddles offer superior substrate-wetting migration due to their natural porosity and consistent thermal conductivity, enhancing the even absorption and curing of coatings. In contrast, ceramic-coated griddles provide a non-porous surface that limits substrate interaction, resulting in less effective wetting and slower migration during the curing process.

Hydrophobicity retention

Soapstone griddles maintain hydrophobicity more effectively than ceramic-coated griddles, ensuring less moisture absorption and enhanced durability during curing processes. This superior water repellence reduces the risk of cracking and prolongs the lifespan of the griddle under high-heat curing conditions.

VOC degassing phase

Soapstone griddles exhibit a slower VOC degassing phase due to their dense, non-porous structure, which absorbs and releases volatile compounds gradually, ensuring a more controlled curing process. Ceramic-coated griddles, with their smooth, sealed surfaces, tend to release VOCs rapidly during initial heating, potentially requiring more precise temperature management to prevent off-gassing odors.

Surface pyrolytic tolerance

Soapstone griddles exhibit superior surface pyrolytic tolerance due to their dense, non-porous mineral composition, allowing them to endure high-temperature curing processes without cracking or degrading. Ceramic-coated griddles offer moderate pyrolytic resistance but are more susceptible to surface chipping and thermal stress during repeated high-heat curing cycles.

Inert substrate diffusion

Soapstone griddles, composed of natural talc and magnesium silicate, provide an inert substrate with low diffusion rates, preserving the purity and flavor integrity during curing processes. Ceramic-coated griddles offer a chemically stable, non-porous surface that minimizes reactive interactions and ensures consistent diffusion resistance for uniform curing results.

Semi-permeable curing barriers

Soapstone griddles provide a semi-permeable curing barrier that allows moisture to escape slowly, enhancing the drying and curing process of meats and cheeses by preventing surface sogginess. Ceramic-coated griddles create a less permeable surface, which can trap humidity and potentially slow curing by retaining excess moisture.

Soapstone griddle vs Ceramic-coated griddle for curing. Infographic

cookingdiff.com

cookingdiff.com