Dry curing involves applying a mixture of salt, sugar, and spices directly to the surface of the meat, drawing out moisture and enhancing flavor through a gradual dehydration process. Equilibrium curing, on the other hand, submerges the meat in a carefully balanced brine solution, allowing salt and curing agents to penetrate evenly without over-salting. Both methods preserve meat by inhibiting bacterial growth, but equilibrium curing ensures consistent salt distribution, while dry curing produces a more intense, concentrated flavor and firmer texture.

Table of Comparison

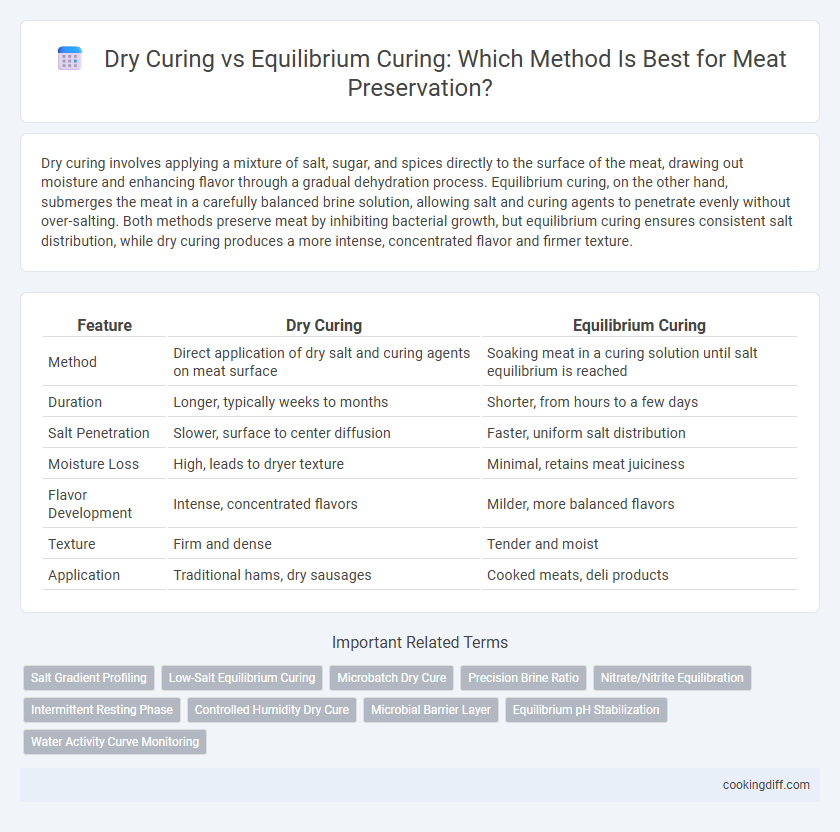

| Feature | Dry Curing | Equilibrium Curing |

|---|---|---|

| Method | Direct application of dry salt and curing agents on meat surface | Soaking meat in a curing solution until salt equilibrium is reached |

| Duration | Longer, typically weeks to months | Shorter, from hours to a few days |

| Salt Penetration | Slower, surface to center diffusion | Faster, uniform salt distribution |

| Moisture Loss | High, leads to dryer texture | Minimal, retains meat juiciness |

| Flavor Development | Intense, concentrated flavors | Milder, more balanced flavors |

| Texture | Firm and dense | Tender and moist |

| Application | Traditional hams, dry sausages | Cooked meats, deli products |

Introduction to Meat Curing Methods

Dry curing involves applying a salt and seasoning mixture directly onto the meat's surface, facilitating moisture removal and flavor infusion through osmosis. This traditional method is favored for its ability to create distinct textures and intense flavors in products like prosciutto and dry-cured bacon.

Equilibrium curing uses a saturated brine solution, balanced to the meat's water content, ensuring uniform salt absorption without excessive moisture loss. This technique offers controlled curing times and consistent results, making it ideal for large-scale processed meats such as hams and sausages.

What is Dry Curing?

Dry curing is a traditional meat preservation method where salt and seasonings are directly rubbed onto the meat's surface to draw out moisture and inhibit bacterial growth. This technique relies on controlled salt concentration and temperature to develop flavor and texture while preventing spoilage.

Dry curing involves applying a precise mixture of salt, sugar, and spices onto the meat, followed by a resting period in a cool, humidity-controlled environment. The process extracts moisture gradually, creating a dense, flavorful product such as prosciutto or dry-cured ham. It contrasts with equilibrium curing, which uses a brine solution to achieve uniform salt saturation throughout the meat.

What is Equilibrium Curing?

| Equilibrium curing | is a precise meat curing method where the meat is soaked in a curing solution with concentrations that equalize with the meat's internal moisture, ensuring uniform salt and preservative distribution. |

| Salt concentration | in the curing solution matches the meat's moisture content, preventing excessive dehydration or uneven curing. |

| Benefits | include consistent flavor, improved texture, and longer shelf life compared to dry curing, making it ideal for high-quality charcuterie products. |

Key Differences: Dry Curing vs Equilibrium Curing

Dry curing involves applying a mixture of salt and spices directly onto the meat's surface, resulting in moisture loss and concentrated flavor, while equilibrium curing submerges the meat in a brine solution that allows salt to penetrate evenly without significant moisture change. Dry curing often requires longer curing times and is preferred for products like traditional prosciutto and dry-cured bacon, whereas equilibrium curing is faster and commonly used for hams and bacons that retain more moisture. The choice between dry curing and equilibrium curing impacts texture, flavor intensity, and preservation, making it crucial for producers to select the method based on desired final product characteristics.

Salt Ratios and Measurements

What are the key differences in salt ratios between dry curing and equilibrium curing methods? Dry curing typically requires a higher salt concentration, often around 3-5% of the meat's weight, to ensure proper preservation and flavor penetration. Equilibrium curing uses a lower, precisely measured salt ratio that gradually reaches balance within the meat, preventing over-salting and ensuring consistent curing throughout.

Flavor Development in Each Method

Dry curing intensifies meat flavor by slowly drawing out moisture, concentrating natural tastes and enhancing umami. Equilibrium curing balances moisture and salt content, resulting in a more uniform and subtle flavor profile.

- Dry curing flavor concentration - Salt penetration is slower, which allows enzymes to break down proteins and fats more thoroughly, developing complex flavors.

- Equilibrium curing consistency - Controlled moisture levels ensure an even cure, maintaining a balanced saltiness without overpowering the natural meat taste.

- Flavor complexity comparison - Dry curing produces bolder, more robust flavors, whereas equilibrium curing yields milder and more refined taste nuances.

Safety Considerations in Curing

Dry curing involves applying a precise amount of salt and curing agents directly to the meat surface, which inhibits bacterial growth by reducing moisture content. Equilibrium curing uses a salt solution, allowing the meat to absorb curing agents evenly, minimizing over-salting and ensuring consistent preservation.

Both methods require careful monitoring of temperature and humidity to prevent pathogen development, especially Clostridium botulinum and Listeria monocytogenes. Proper use of curing salts containing nitrites or nitrates is essential to inhibit microbial growth and enhance food safety in cured meats.

Time Requirements for Each Curing Process

Dry curing typically requires a longer time frame, often several weeks, due to the direct application of curing salts and slow moisture removal. Equilibrium curing is generally faster, using a brine solution to balance salt concentration quickly and evenly within the meat.

- Dry curing time - Can range from 2 to 8 weeks depending on meat thickness and desired flavor intensity.

- Equilibrium curing time - Usually completed within 1 to 3 weeks, as the diffusion process is accelerated by the brine.

- Moisture loss rate - Slower in dry curing, contributing to longer curing periods and firmer texture development.

Time efficiency and flavor profile are key considerations when choosing between dry curing and equilibrium curing methods for meat.

Application: Choosing the Right Curing Method

Dry curing involves applying a precise amount of salt and curing agents directly onto the meat surface, ideal for smaller cuts or when a concentrated flavor profile is desired. Equilibrium curing uses a brine solution with salt concentrations calculated to balance moisture and salt uptake, making it suitable for larger cuts to ensure uniform curing throughout. Selecting the right curing method depends on the meat size, desired texture, and flavor intensity, with dry curing emphasizing surface treatment and equilibrium curing providing consistent internal penetration.

Related Important Terms

Salt Gradient Profiling

Dry curing creates a pronounced salt gradient in the meat, with higher salt concentrations near the surface and lower levels internally, promoting distinct flavor development and texture changes. Equilibrium curing achieves a uniform salt distribution by balancing salt concentration throughout the meat, resulting in consistent curing and moisture retention.

Low-Salt Equilibrium Curing

Low-salt equilibrium curing ensures precise moisture balance by allowing salt to diffuse uniformly, reducing sodium content while preventing microbial growth and spoilage. This method enhances flavor development and texture stability compared to traditional dry curing, particularly in large cuts of meat requiring controlled salt penetration.

Microbatch Dry Cure

Microbatch Dry Cure employs a controlled, small-scale approach to dry curing, enhancing flavor penetration and consistent salt distribution compared to traditional dry curing methods. Unlike equilibrium curing, which uses precise solute concentrations for uniform moisture and salt balance, microbatch dry cure relies on careful manual application to achieve optimal meat preservation and taste development.

Precision Brine Ratio

Dry curing relies on applying salt directly to the meat, resulting in a less precise brine ratio due to variable moisture content, whereas equilibrium curing uses a carefully calculated brine solution to achieve exact salt concentration and uniform curing. Precision in brine ratio during equilibrium curing ensures consistent preservation, flavor development, and safety by maintaining controlled osmotic balance within the meat.

Nitrate/Nitrite Equilibration

Dry curing relies on direct application of salt and nitrates/nitrites to the meat surface, resulting in slower and less uniform nitrate/nitrite equilibration compared to equilibrium curing, which uses immersion or controlled environments to maintain consistent curing solution concentration throughout the product. Equilibrium curing enhances nitrate/nitrite penetration and stabilization, ensuring more reliable preservation, color development, and flavor in cured meat products.

Intermittent Resting Phase

The intermittent resting phase in dry curing allows salt to gradually penetrate meat fibers, enhancing flavor development and moisture retention by enabling osmotic balance. Equilibrium curing minimizes this phase, using precise brine concentrations to maintain consistent salt distribution, reducing curing time while ensuring even seasoning and texture.

Controlled Humidity Dry Cure

Controlled humidity dry cure precisely regulates moisture levels, enhancing flavor development and ensuring consistent salt penetration in meat. This method minimizes surface drying while promoting uniform curing, resulting in superior texture and preservation compared to traditional dry curing or equilibrium curing techniques.

Microbial Barrier Layer

Dry curing forms a dense microbial barrier layer on the meat surface by drawing out moisture, which inhibits pathogen growth and enhances preservation. Equilibrium curing allows uniform salt penetration without excessive dehydration, maintaining an effective microbial barrier inside the meat to prevent spoilage.

Equilibrium pH Stabilization

Equilibrium curing stabilizes the pH within meat by allowing curing agents to penetrate evenly, optimizing flavor development and texture retention. Unlike dry curing, this method reduces surface drying and spoilage risks, ensuring consistent preservation throughout the product.

Dry Curing vs Equilibrium Curing for curing meat. Infographic

cookingdiff.com

cookingdiff.com