Charcuterie curing involves controlled drying and aging techniques that develop complex flavors and firm textures in sausages, relying heavily on precise temperature and humidity management. Nduja-style curing incorporates a higher fat content and spicy seasonings, resulting in a softer, spreadable texture and bold, piquant taste profile. Understanding these distinct curing methods allows artisans to tailor sausage characteristics for specific culinary applications and flavor experiences.

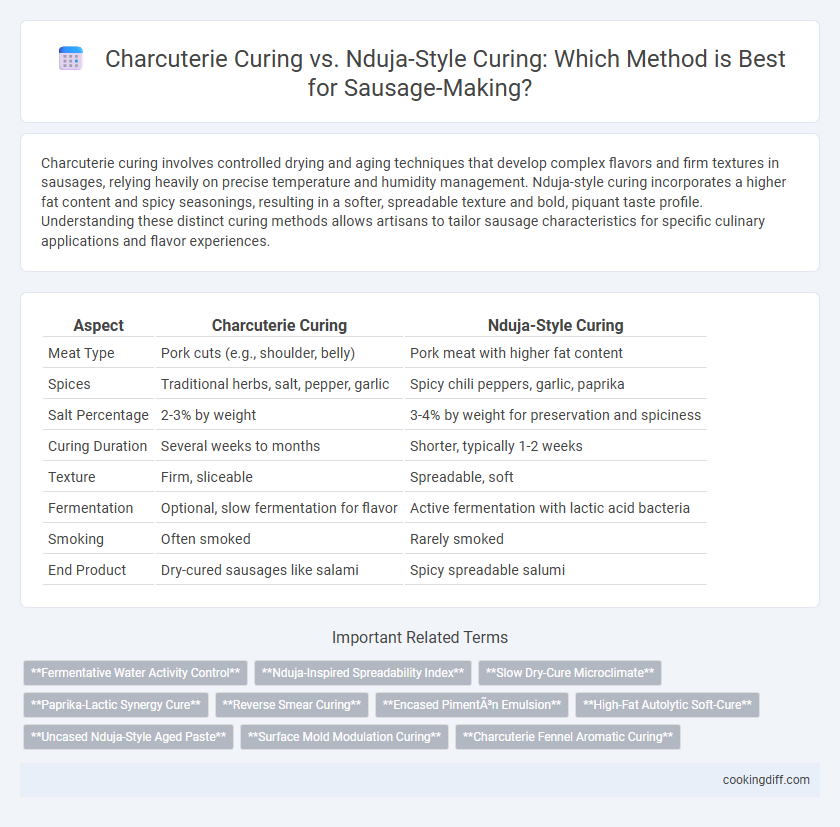

Table of Comparison

| Aspect | Charcuterie Curing | Nduja-Style Curing |

|---|---|---|

| Meat Type | Pork cuts (e.g., shoulder, belly) | Pork meat with higher fat content |

| Spices | Traditional herbs, salt, pepper, garlic | Spicy chili peppers, garlic, paprika |

| Salt Percentage | 2-3% by weight | 3-4% by weight for preservation and spiciness |

| Curing Duration | Several weeks to months | Shorter, typically 1-2 weeks |

| Texture | Firm, sliceable | Spreadable, soft |

| Fermentation | Optional, slow fermentation for flavor | Active fermentation with lactic acid bacteria |

| Smoking | Often smoked | Rarely smoked |

| End Product | Dry-cured sausages like salami | Spicy spreadable salumi |

Understanding Charcuterie Curing: Foundations and Techniques

Charcuterie curing relies on controlled salt, nitrates, and temperature to preserve meats while developing complex flavors through enzymatic activity. Nduja-style curing emphasizes a spicier, wetter texture achieved by incorporating chili peppers and higher fat content in the fermentation process.

- Salt and Nitrate Balance - Essential for inhibiting bacterial growth and promoting safe preservation in traditional charcuterie curing.

- Temperature and Humidity Control - Precise environmental settings regulate fermentation speed and texture development in cured sausages.

- Spice and Fat Integration - Nduja-style curing incorporates chili peppers and increased fat to create a spreadable, intensely flavored product.

Nduja-Style Curing: A Spicy Southern Italian Tradition

| Nduja-Style Curing | Originates from Calabria, Southern Italy, known for its spicy, spreadable sausage texture. |

| Ingredients | Uses high amounts of chili peppers, pork fat, and a blend of aromatic spices to create heat and flavor depth. |

| Process | Involves fermentation at controlled temperatures followed by slow drying to develop distinct spicy tang and soft consistency. |

| Comparison to Charcuterie Curing | Nduja curing emphasizes intense spice and spreadability while traditional charcuterie curing focuses on varied textures and balanced flavors. |

| Texture & Flavor | Soft, spreadable texture with a bold, fiery aroma characteristic of Southern Italian cured meats. |

Key Differences Between Charcuterie and Nduja-Style Curing

Charcuterie curing involves a slow, controlled drying and aging process to develop complex flavors and firm textures in sausages. Nduja-style curing uses a higher fat content and incorporates spicy Calabrian peppers, resulting in a softer, spreadable sausage with a distinct heat profile. The key difference lies in texture and spice level, with charcuterie emphasizing firmness and nuanced flavor versus nduja's creamy consistency and bold spiciness.

Selecting Meats: Charcuterie vs Nduja Sausage Making

Choosing meats for charcuterie curing involves selecting high-quality cuts like pork shoulder and belly, which provide the ideal fat-to-lean ratio essential for flavor and texture. These cuts are typically cured with precise salt and spice blends to develop complex flavors over extended aging periods.

Nduja-style curing uses fattier cuts and trimmings to achieve its characteristic soft, spreadable texture and spicy profile, often incorporating Calabrian chili peppers during the curing process. The meat selection prioritizes fattiness and coarseness, creating a distinctively rich and piquant sausage suited for quicker curing times.

Spice Profiles in Charcuterie vs Nduja-Style Sauasages

How do the spice profiles differ between charcuterie curing and nduja-style curing in sausage-making? Charcuterie curing typically uses a balanced blend of herbs like thyme, bay leaves, and black pepper to enhance natural meat flavors. Nduja-style curing relies heavily on bold spices such as Calabrian chili peppers and paprika, creating a spicy, smoky profile unique to southern Italian sausages.

Texture Outcomes from Charcuterie and Nduja-Style Curing

Charcuterie curing typically yields a firm, dense texture in sausages due to controlled drying and aging processes. Nduja-style curing produces a softer, spreadable texture that is rich in fat and spice infusion.

- Firmness in Charcuterie Curing - Slow curing and low moisture content create a compact, chewy texture.

- Softness in Nduja-Style Curing - High fat content and less drying result in a creamy, spreadable consistency.

- Flavor Penetration Differences - Nduja's spices and fat enhance texture by keeping the sausage moist and pliable.

Fermentation Processes: Traditional Charcuterie vs Nduja

Traditional charcuterie curing relies on slow fermentation with specific bacterial cultures to develop flavor and preserve the meat. Nduja-style curing involves a faster, spicy fermentation using higher fat content and chili peppers to create its distinctive soft texture and tangy taste.

- Traditional Charcuterie Fermentation - Utilizes controlled temperature and humidity to encourage beneficial microbes that enhance umami flavors over weeks.

- Nduja Fermentation Process - Incorporates capsaicin from chili which accelerates microbial activity, resulting in a more vigorous fermentation.

- Microbial Environment - Charcuterie depends on surface mold and lactic acid bacteria, while Nduja favors anaerobic fermentation driven by specific fermentative bacteria in a spicy medium.

These differences in fermentation techniques influence the texture, taste, and preservation characteristics distinctive to each sausage style.

Salt and Fat Ratios: Impact on Flavor and Preservation

Charcuterie curing typically employs a precise salt ratio of 2-3% by weight to ensure effective preservation and balanced flavor development, while nduja-style curing incorporates higher fat content, often exceeding 50%, combined with a similar salt concentration to achieve its characteristic soft texture and spicy profile. The elevated fat ratio in nduja influences the curing duration and flavor diffusion, enhancing both richness and mouthfeel, whereas traditional charcuterie relies more heavily on salt-induced moisture reduction for shelf stability. Differences in salt concentration and fat ratios critically impact microbial activity, curing time, and the final flavor complexity of the sausage product.

Iconic Recipes: Classic Charcuterie vs Homemade Nduja

Classic charcuterie curing involves slow aging of whole muscle cuts, emphasizing flavor development through controlled salt, spice, and air exposure. Nduja-style curing focuses on a spicy, spreadable sausage crafted with pork, Calabrian chili peppers, and a distinctive fermentation process.

Iconic charcuterie recipes like prosciutto and coppa rely on precise temperature and humidity control for optimal texture and taste. Homemade nduja demands a unique balance of heat and fat content, producing a creamy consistency and bold flavor profile. Both methods showcase regional culinary traditions and require expert timing to perfect the curing process.

Related Important Terms

Fermentative Water Activity Control

Fermentative water activity control in charcuterie curing relies on precise salt concentration and slow drying to inhibit undesirable microbial growth while promoting beneficial fermentation. Nduja-style curing employs a higher moisture content and lactic acid bacteria-driven fermentation to lower water activity rapidly, creating a soft texture and distinctive tang, critical for its spreadable consistency.

Nduja-Inspired Spreadability Index

Nduja-style curing enhances sausage softness through increased moisture content and a finely ground meat blend, resulting in a higher Nduja-Inspired Spreadability Index compared to traditional charcuterie curing methods. This curing technique optimizes fat distribution and fermentation, creating a creamy texture essential for spreadable sausages.

Slow Dry-Cure Microclimate

Charcuterie curing relies on a carefully controlled slow dry-cure microclimate with consistent temperature around 55-60degF and 70-80% humidity to promote even fermentation and prevent spoilage. In contrast, nduja-style curing uses a more humid environment with higher temperatures near 65-70degF, accelerating fat fermentation and creating the spreadable texture unique to nduja sausages.

Paprika-Lactic Synergy Cure

Paprika-Lactic synergy cure enhances flavor development and preservation in sausage-making by combining the antioxidant properties of paprika with the acidification effects of lactic cultures, creating a balanced environment that inhibits spoilage and promotes desirable microbial activity. This approach contrasts traditional charcuterie curing, where paprika contributes color and mild flavor but relies heavily on salt and nitrates, whereas nduja-style curing leverages lactic fermentation to achieve a tangy profile alongside the spicy paprika infusion.

Reverse Smear Curing

Reverse smear curing in charcuterie achieves a controlled development of beneficial surface bacteria by inoculating sausages with specific cultures after initial drying, enhancing flavor complexity without over-ripening. Nduja-style curing typically bypasses this step, relying instead on a wetter, spiced mixture and natural fermentation, resulting in a softer texture and distinct tang.

Encased Pimentón Emulsion

Encased pimenton emulsion in charcuterie curing involves a controlled drying process that intensifies smoky paprika flavors while preserving texture, creating a balanced, firm sausage. Nduja-style curing emphasizes a softer emulsion with higher fat content and spice concentration, resulting in a spreadable sausage rich in smoky, piquant notes.

High-Fat Autolytic Soft-Cure

High-fat autolytic soft-cure in charcuterie emphasizes precise enzymatic breakdown for tender texture and nuanced flavor, whereas nduja-style curing utilizes high-fat content combined with spices to promote rapid fermentation and a spreadable consistency. The soft-curing process in nduja incorporates robust microbial activity, enhancing preservation while intensifying heat and aroma, distinguishing it from traditional charcuterie curing methods that prioritize delicate drying and aging.

Uncased Nduja-Style Aged Paste

Uncased Nduja-style aged paste features a high-fat content blended with spices and slow fermentation, producing a soft, spreadable texture distinct from traditional charcuterie curing that typically requires casing and firm consistency. This method enhances flavor complexity through microbial activity and moisture reduction without the structural constraints of sausage casings, resulting in a unique, intensely flavored cured meat product.

Surface Mold Modulation Curing

Surface mold modulation curing in charcuterie involves controlled inoculation with beneficial molds like Penicillium nalgiovense to promote flavor development and prevent harmful microbial growth, whereas Nduja-style curing relies more on high spice content and natural fermentation without a prominent surface mold. This difference impacts the sausage's texture, safety, and aroma profile, with surface mold curing offering enhanced protection and complexity compared to the rustic, spicy fermentation of Nduja-style sausages.

Charcuterie Curing vs Nduja-Style Curing for sausage-making Infographic

cookingdiff.com

cookingdiff.com