Traditional woks, typically made from carbon steel or cast iron, offer excellent heat retention and even cooking, making them suitable for curing processes involving high-heat searing and flavor development. Black steel woks, crafted from thicker carbon steel with a darker finish, heat up quickly and maintain a stable temperature, providing superior control during the curing method that requires consistent heat application. Choosing between traditional and black steel woks for curing depends on the desired heat responsiveness and durability, with black steel often favored for its precision in temperature control and long-lasting seasoning.

Table of Comparison

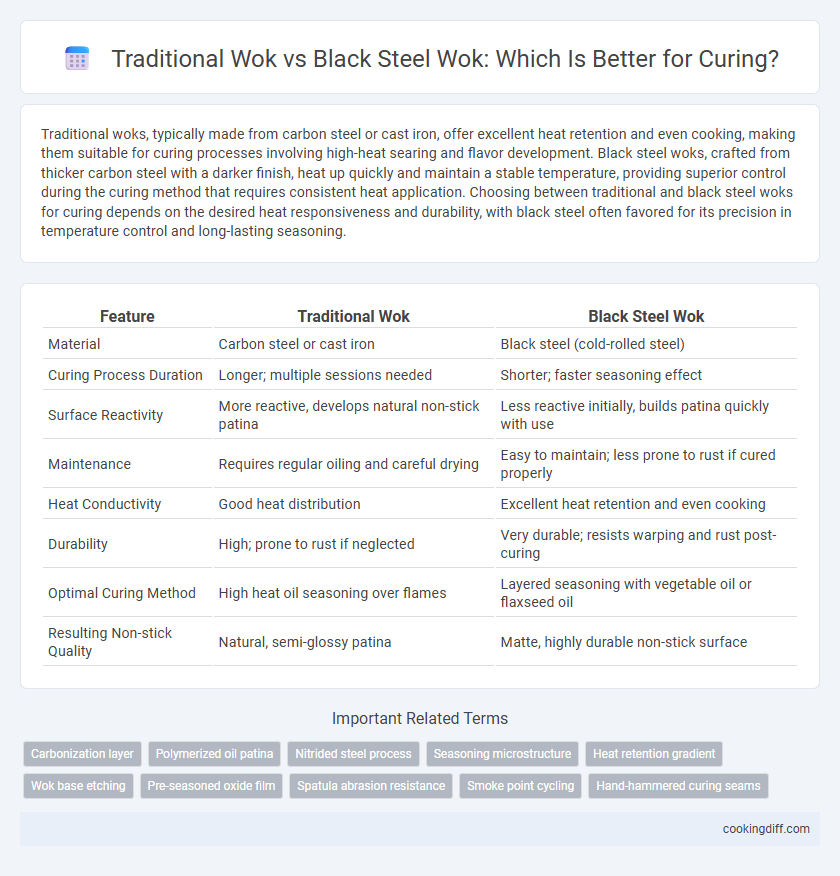

| Feature | Traditional Wok | Black Steel Wok |

|---|---|---|

| Material | Carbon steel or cast iron | Black steel (cold-rolled steel) |

| Curing Process Duration | Longer; multiple sessions needed | Shorter; faster seasoning effect |

| Surface Reactivity | More reactive, develops natural non-stick patina | Less reactive initially, builds patina quickly with use |

| Maintenance | Requires regular oiling and careful drying | Easy to maintain; less prone to rust if cured properly |

| Heat Conductivity | Good heat distribution | Excellent heat retention and even cooking |

| Durability | High; prone to rust if neglected | Very durable; resists warping and rust post-curing |

| Optimal Curing Method | High heat oil seasoning over flames | Layered seasoning with vegetable oil or flaxseed oil |

| Resulting Non-stick Quality | Natural, semi-glossy patina | Matte, highly durable non-stick surface |

Introduction to Wok Curing: Why It Matters

Curing a wok is essential to create a natural non-stick surface and prevent rust, making it a crucial step for both traditional and black steel woks. Proper curing enhances heat retention and improves cooking performance over time.

- Traditional wok materials - Usually made from carbon steel, they require seasoning to build a protective patina that resists rust and sticks.

- Black steel woks - Similar in composition but often thicker, they benefit from curing to develop durability and a natural non-stick coating.

- Curing process impact - Effective curing improves flavor infusion and prolongs the wok's lifespan regardless of the material.

Traditional Woks: Materials and Curing Process

Traditional woks are typically crafted from carbon steel or cast iron, both known for excellent heat retention and distribution. The curing process involves seasoning the wok with oil to create a non-stick surface and prevent rusting.

- Material Composition - Carbon steel woks are lightweight and responsive to heat changes, while cast iron woks offer superior heat retention but require longer curing periods.

- Seasoning Process - Repeated oiling and heating build up a protective patina that enhances the wok's durability and non-stick properties.

- Maintenance After Curing - Proper drying and light oil application after each use maintain the seasoning and prolong the wok's lifespan.

Black Steel Woks: Construction and Curing Needs

Black steel woks are crafted from a sturdy alloy that combines durability with excellent heat retention, making them ideal for high-temperature cooking. Their unique construction demands a specific curing process to develop a natural non-stick surface and prevent rust.

Curing a black steel wok involves applying a thin layer of oil and heating it to polymerize the oil, creating a protective seasoning layer. Unlike traditional woks, black steel requires regular re-seasoning to maintain its surface integrity and enhance cooking performance. Proper curing extends the wok's lifespan and improves flavor development by reducing metallic taste and enhancing heat distribution.

Key Differences in Wok Composition

| Aspect | Traditional Wok | Black Steel Wok |

|---|---|---|

| Material Composition | Typically made from carbon steel with a thicker gauge, allowing even heat distribution and durability. | Constructed from black steel, which is denser and has a smoother surface, promoting faster seasoning and improved non-stick properties. |

| Heat Retention & Distribution | Offers steady heat retention, ideal for slow curing processes and maintaining consistent temperatures. | Heats up quickly due to thinner metal thickness but may cool faster, affecting curing precision. |

| Seasoning Characteristics | Traditional carbon steel forms a natural patina over time, enhancing flavor and curing quality. | Black steel's smoother surface results in faster and more uniform seasoning, reducing curing residue. |

Heat Conductivity: Impact on Curing Efficiency

Traditional wok materials like carbon steel offer excellent heat conductivity, ensuring even temperature distribution critical for effective curing processes. Black steel woks, known for their slightly thicker construction, retain heat longer but may heat less uniformly, potentially affecting curing consistency. Selecting the right wok depends on balancing rapid heat conduction for quick curing against heat retention for prolonged cooking phases.

Seasoning Techniques: Traditional vs Black Steel

Traditional woks, often made from carbon steel, require a careful seasoning process involving repeated oil applications and high heat to build a natural non-stick patina. Black steel woks, known for their thicker material, benefit from seasoning methods that involve longer heating times and oil polymerization to enhance durability and rust resistance.

Seasoning techniques for traditional woks emphasize patience and gradual layers of oil curing to prevent rust and ensure even cooking surfaces. In contrast, black steel woks' seasoning focuses on creating a robust, hardened surface faster due to their higher carbon content, promoting long-lasting performance in high-heat cooking.

Flavor Development: How Curing Transforms Each Wok

Traditional woks develop a natural non-stick surface through repeated curing that enhances subtle smoky flavors infused during cooking. Black steel woks, with their denser material, undergo a curing process that creates a robust seasoning layer, intensifying umami and depth in stir-fried dishes.

- Curing in traditional woks promotes even heat distribution - this allows slow flavor absorption from oils and spices, enriching the food's taste complexity.

- Black steel woks' patina offers increased heat retention - accelerating the Maillard reaction that deepens the flavor profile of cooked ingredients.

- Seasoning layers differ in aroma release - traditional woks tend to impart a gentle smokiness, while black steel imparts a stronger, toasted aroma.

The curing method directly influences the wok's ability to enhance and develop distinctive flavors with each use.

Maintenance and Recuring: Best Practices

Traditional woks require frequent seasoning to maintain a non-stick surface and prevent rust, with thorough cleaning and drying after each use to extend their lifespan. Black steel woks benefit from faster curing due to their thinner metal, allowing for more efficient seasoning cycles and easier maintenance. Regular re-seasoning using oil application and controlled heating ensures optimal performance and longevity for both types of woks.

Pros and Cons: Traditional Wok vs Black Steel Wok

Which wok is better for curing, traditional or black steel? Traditional woks, often made from carbon steel or cast iron, provide excellent heat retention and a natural non-stick surface after seasoning, but they require regular maintenance to prevent rust. Black steel woks offer faster heating and lightweight handling, yet they may lack the durability and even heat distribution found in traditional woks.

Related Important Terms

Carbonization layer

Traditional woks develop a natural carbonization layer over time through repeated seasoning and heat exposure, enhancing their non-stick properties and resistance to rust. Black steel woks achieve a similar carbonization layer faster due to their thinner metal construction and higher heat conductivity, allowing for quicker curing and improved durability in cooking.

Polymerized oil patina

Traditional woks develop a natural polymerized oil patina through repeated seasoning, enhancing non-stick properties and corrosion resistance. Black steel woks, favored for their thicker metal and smoother surface, achieve a more uniform and durable polymerized oil layer that improves curing efficiency and longevity.

Nitrided steel process

Black steel woks undergo a nitrided steel process that enhances surface hardness and corrosion resistance, making them ideal for traditional curing methods by preventing rust and maintaining seasoning integrity. Traditional woks lack this treatment, resulting in slower curing and higher susceptibility to oxidation during the seasoning phase.

Seasoning microstructure

Traditional wok seasoning forms a heterogeneous polymerized oil layer that enhances non-stick properties but often lacks long-term durability. Black steel woks develop a more uniform oxide and carbonized oil microstructure during curing, resulting in superior corrosion resistance and a stable, long-lasting seasoning layer.

Heat retention gradient

Traditional woks, typically made of carbon steel or cast iron, exhibit superior heat retention with a steep heat retention gradient that ensures consistent temperature control during curing. Black steel woks, due to their denser material composition, maintain a more even heat distribution, minimizing hot spots and enhancing the curing process with improved thermal stability.

Wok base etching

Traditional wok bases, often made from carbon steel, develop a natural patina through repeated cooking and curing, enhancing non-stick properties and flavor depth. Black steel woks undergo a specific etching process on their base to create a roughened surface that accelerates seasoning adherence, resulting in improved durability and corrosion resistance compared to untreated traditional woks.

Pre-seasoned oxide film

Traditional woks often feature a pre-seasoned oxide film formed through high-heat curing, providing a natural non-stick surface that improves with use, while black steel woks typically require repeated seasoning cycles to develop a durable, corrosion-resistant oxide layer for optimal curing. The quality of the pre-seasoned oxide film directly influences the wok's seasoning retention, heat distribution, and resistance to rust, making curing techniques critical for enhancing cooking performance in both materials.

Spatula abrasion resistance

Black steel woks exhibit superior spatula abrasion resistance compared to traditional woks, maintaining a smoother surface throughout the curing process and reducing wear. This durability enhances the seasoning layer development, ensuring a more evenly cured cooking surface over time.

Smoke point cycling

Traditional woks, often made from carbon steel or cast iron, typically handle smoke point cycling well but may lose seasoning over repeated high-heat curing processes, affecting durability and non-stick properties. Black steel woks, with their superior oxidation resistance and enhanced seasoning retention, offer improved performance in smoke point cycling, maintaining structural integrity and consistent cooking quality during prolonged curing stages.

Traditional wok vs black steel wok for curing. Infographic

cookingdiff.com

cookingdiff.com