Salt curing preserves utensils by drawing out moisture, creating an environment that inhibits bacterial growth and extends their lifespan. Koji curing utilizes enzymes from the koji mold to break down residues and prevent odor buildup, enhancing cleanliness and durability. Both methods offer effective preservation, with salt curing emphasizing moisture control and koji curing promoting natural enzymatic cleaning.

Table of Comparison

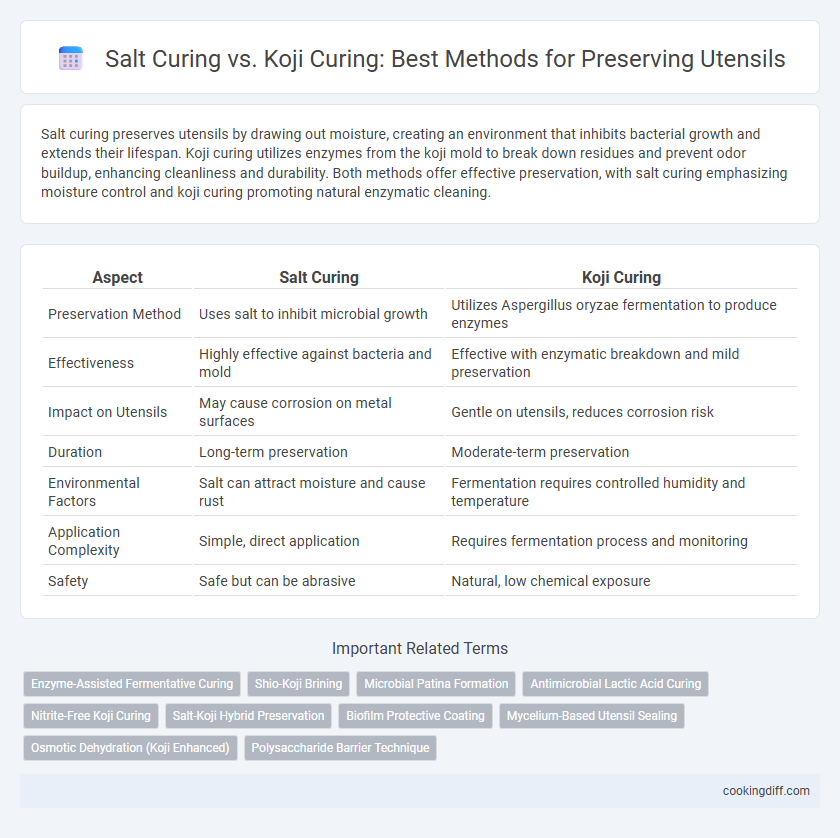

| Aspect | Salt Curing | Koji Curing |

|---|---|---|

| Preservation Method | Uses salt to inhibit microbial growth | Utilizes Aspergillus oryzae fermentation to produce enzymes |

| Effectiveness | Highly effective against bacteria and mold | Effective with enzymatic breakdown and mild preservation |

| Impact on Utensils | May cause corrosion on metal surfaces | Gentle on utensils, reduces corrosion risk |

| Duration | Long-term preservation | Moderate-term preservation |

| Environmental Factors | Salt can attract moisture and cause rust | Fermentation requires controlled humidity and temperature |

| Application Complexity | Simple, direct application | Requires fermentation process and monitoring |

| Safety | Safe but can be abrasive | Natural, low chemical exposure |

Introduction to Curing Techniques for Utensil Preservation

Salt curing is a traditional technique that uses salt to draw out moisture from utensils, preventing microbial growth and corrosion. This method is widely valued for its simplicity and effectiveness in preserving metal and wooden kitchen tools.

Koji curing, involving fermentation with Aspergillus oryzae mold, enhances utensil preservation by creating an antimicrobial environment and improving durability. This innovative approach also adds a unique enzymatic protection that extends the lifespan of culinary equipment.

Understanding Salt Curing: Principles and Process

Salt curing preserves utensils by drawing out moisture through osmosis, creating an environment hostile to bacteria and mold. This process relies on salt's hygroscopic properties and typically requires a consistent application to ensure thorough preservation.

- Osmosis Principle - Salt extracts moisture from utensil surfaces, inhibiting microbial growth.

- Salt Concentration - Adequate salinity levels are crucial for effective curing and preventing spoilage.

- Application Method - Uniform salt coverage ensures even preservation and extends utensil lifespan.

Understanding the salt curing process is essential for maintaining hygiene and durability in preserved utensils.

What Is Koji Curing? A Brief Overview

| Koji Curing | Koji curing utilizes Aspergillus oryzae mold to ferment and preserve utensils, enhancing durability and introducing natural antimicrobial properties. This method promotes enzymatic breakdown of organic residues, preventing microbial growth without harsh chemicals. Unlike traditional salt curing which relies on high sodium concentration for preservation, koji curing offers a more sustainable and eco-friendly alternative for utensil maintenance. |

Chemical Mechanisms: Salt vs. Koji Curing

Salt curing preserves utensils by drawing out moisture through osmotic pressure, creating an inhospitable environment for bacterial growth. The high sodium chloride concentration denatures proteins and inhibits enzymatic activities that cause degradation.

Koji curing uses Aspergillus oryzae mold enzymes to break down starches and proteins into simpler compounds, fostering beneficial microbial activity that inhibits spoilage. This enzymatic process produces organic acids and peptides, lowering pH and enhancing preservation. The biochemical transformations in koji curing provide a natural antimicrobial barrier distinct from the dehydrating effect of salt curing.

Impact on Utensil Longevity and Performance

Salt curing creates a dehydrating environment that inhibits microbial growth on utensils, effectively extending their lifespan by preventing rust and decay. Koji curing, utilizing enzymatic fermentation, enhances utensil surface resilience and performance by promoting a natural protective coating that resists corrosion.

- Salt curing inhibits microbial activity - Salt draws out moisture, reducing the risk of rust and bacterial damage to metal utensils.

- Koji curing forms a protective enzymatic layer - The fermentation process creates enzymes that coat utensils, improving resistance to wear and corrosion.

- Utensil longevity differs by method - Salt curing mainly prevents physical deterioration, while koji curing also enhances surface durability and functional performance.

Comparative Effectiveness: Salt vs. Koji for Preservation

Which method between salt curing and koji curing offers superior preservation for utensils? Salt curing provides a robust antimicrobial barrier by drawing out moisture and inhibiting bacterial growth, making it highly effective for long-term storage. Koji curing employs enzymatic fermentation, enhancing preservation through microbial activity that breaks down organic residues and prevents spoilage while maintaining material integrity.

Sensory Effects: Texture, Aroma, and Appearance of Utensils

Salt curing enhances the texture of utensils by creating a firm, slightly rough surface while imparting a saline aroma that suggests cleanliness and preservation. Koji curing introduces enzymatic activity that softens the utensil surfaces, producing a subtle sweet and umami scent with a glossy, polished appearance. Sensory differences between salt and koji curing are pronounced, with salt curing emphasizing dryness and sharpness, whereas koji curing offers a delicate, fermented character enhancing tactile and olfactory appeal.

Health and Safety Implications of Each Method

Salt curing preserves utensils by inhibiting microbial growth through osmotic pressure, but excess salt residue can cause corrosion and pose health risks if ingested. Koji curing employs enzymes from Aspergillus oryzae to break down organic matter, offering a natural antimicrobial effect with lower corrosive impact and reduced chemical residue. Health implications favor koji curing for its gentle, enzymatic preservation, while salt curing demands careful handling to prevent salt-induced damage and potential toxicity.

Environmental and Sustainability Considerations

Salt curing for preserving utensils relies on abundant mineral resources but can contribute to soil salinization and water contamination when runoff occurs. The environmental footprint includes high salt extraction energy and potential ecosystem disruption near salt harvest sites.

Koji curing utilizes mold fermentation with minimal waste and lower resource consumption, offering a more sustainable preservation method by enhancing biodegradability and reducing chemical residues. This technique supports circular economies by using natural enzymes, promoting eco-friendly utensil maintenance with a smaller ecological impact.

Related Important Terms

Enzyme-Assisted Fermentative Curing

Salt curing preserves utensils by creating a hypertonic environment that inhibits microbial growth through dehydration, while koji curing utilizes enzyme-assisted fermentative curing where Aspergillus oryzae enzymes break down organic residues, enhancing antimicrobial properties and facilitating deeper sterilization. Enzyme-assisted fermentative curing with koji accelerates biodegradation of contaminants and promotes a natural, eco-friendly preservation process compared to the traditional salt curing method.

Shio-Koji Brining

Shio-Koji brining utilizes a blend of salt and fermented rice malt koji to enhance preservation by promoting natural enzymatic activity that inhibits microbial growth and improves flavor complexity in utensils. Unlike traditional salt curing, shio-koji brining not only preserves but also gently conditions surfaces, reducing corrosion while infusing subtle umami elements beneficial for longevity and maintenance.

Microbial Patina Formation

Salt curing promotes the growth of halophilic microbes that form a protective microbial patina on utensils, enhancing preservation by inhibiting harmful bacteria. Koji curing utilizes Aspergillus oryzae fermentation, generating enzymes that create a distinct, beneficial biofilm, accelerating patina development and improving utensil longevity.

Antimicrobial Lactic Acid Curing

Salt curing relies on high salinity to inhibit microbial growth on utensils, creating an environment hostile to spoilage organisms by drawing moisture out through osmotic pressure. Koji curing utilizes Aspergillus oryzae to produce lactic acid and other antimicrobial compounds, offering a natural biopreservative effect that enhances utensil sanitation through fermentation-driven lactic acid production.

Nitrite-Free Koji Curing

Salt curing involves applying salt to utensils to inhibit microbial growth through dehydration, but can cause corrosion and leave residue; nitrite-free koji curing uses Aspergillus oryzae enzymes to naturally preserve without harmful chemicals, reducing oxidation and extending utensil lifespan with eco-friendly, safe antimicrobial effects. Koji curing enhances preservation by promoting beneficial microbial activity and generating antimicrobial compounds, making it an optimal, sustainable alternative to traditional salt curing for maintaining utensil hygiene and durability.

Salt-Koji Hybrid Preservation

Salt-koji hybrid preservation combines the antimicrobial properties of salt with the enzymatic activity of koji mold, enhancing the sterilization and flavor infusion of utensils during curing. This method accelerates curing time while maintaining the structural integrity and longevity of preserved items compared to traditional salt curing alone.

Biofilm Protective Coating

Salt curing creates a hypertonic environment that dehydrates microbial cells, effectively inhibiting biofilm formation on utensils by disrupting microbial adhesion and growth. Koji curing utilizes enzymatic activity from Aspergillus oryzae to produce protective biofilms rich in antimicrobial peptides, forming a natural coating that preserves utensils while preventing pathogenic colonization.

Mycelium-Based Utensil Sealing

Salt curing preserves utensils by drawing out moisture to inhibit microbial growth, while koji curing employs Aspergillus oryzae mycelium to create a natural, breathable seal that enhances durability and antimicrobial properties. Mycelium-based utensil sealing promotes eco-friendly preservation by forming a bioactive barrier that resists decay and extends the lifespan of kitchen tools.

Osmotic Dehydration (Koji Enhanced)

Salt curing relies on osmotic dehydration by drawing moisture out of utensils, effectively inhibiting microbial growth through high salt concentration. Koji curing enhances osmotic dehydration by utilizing enzymes from Aspergillus oryzae, which break down organic matter and accelerate moisture loss, leading to improved preservation efficacy and reduced curing time.

Salt curing vs koji curing for preserving utensils. Infographic

cookingdiff.com

cookingdiff.com