A lodge skillet offers a durable, cast iron option ideal for slow curing processes due to its excellent heat retention and even distribution. Pre-seasoned carbon steel skillets heat up faster and provide a naturally non-stick surface, making them suitable for quicker curing tasks while requiring less maintenance. Both skillets enhance curing by maintaining consistent temperatures, but the choice depends on the curing duration and the level of care preferred.

Table of Comparison

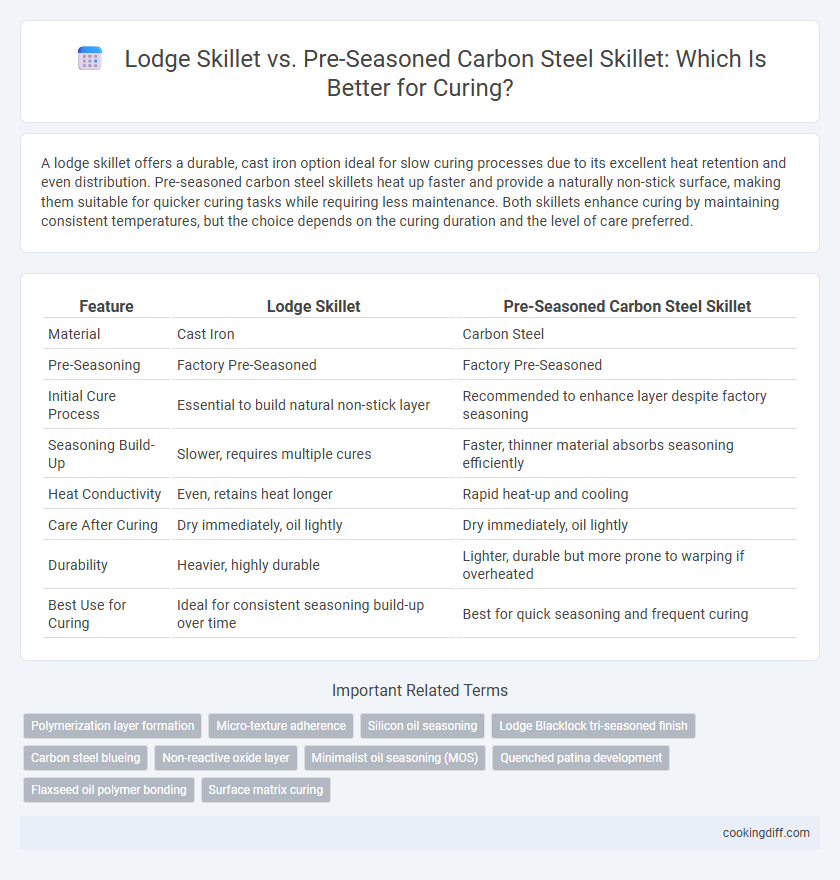

| Feature | Lodge Skillet | Pre-Seasoned Carbon Steel Skillet |

|---|---|---|

| Material | Cast Iron | Carbon Steel |

| Pre-Seasoning | Factory Pre-Seasoned | Factory Pre-Seasoned |

| Initial Cure Process | Essential to build natural non-stick layer | Recommended to enhance layer despite factory seasoning |

| Seasoning Build-Up | Slower, requires multiple cures | Faster, thinner material absorbs seasoning efficiently |

| Heat Conductivity | Even, retains heat longer | Rapid heat-up and cooling |

| Care After Curing | Dry immediately, oil lightly | Dry immediately, oil lightly |

| Durability | Heavier, highly durable | Lighter, durable but more prone to warping if overheated |

| Best Use for Curing | Ideal for consistent seasoning build-up over time | Best for quick seasoning and frequent curing |

Introduction to Skillet Curing

Proper curing of a Lodge skillet enhances its natural non-stick properties and prevents rust. Pre-seasoned carbon steel skillets arrive ready for use but benefit significantly from additional curing to build a durable seasoning layer.

Curing involves applying thin layers of oil and heating the skillet to polymerize the oil, creating a protective coating. Lodge skillets, made from cast iron, develop a robust seasoning over time through repeated curing cycles. Carbon steel skillets, being lighter and thinner, require careful curing to prevent warping and ensure even seasoning.

What is a Lodge Skillet?

A Lodge skillet is a cast iron pan known for its durability and excellent heat retention, making it ideal for curing and seasoning processes. It comes pre-seasoned with oil, providing a natural, easy-release finish that improves with use.

- Material - Made from cast iron, offering even heating and long-lasting performance.

- Pre-seasoned Surface - Comes ready to use with a factory-applied seasoning layer that enhances with continued curing.

- Maintenance - Requires regular oiling after cleaning to maintain the non-stick surface and prevent rusting.

Overview of Pre-Seasoned Carbon Steel Skillets

Pre-seasoned carbon steel skillets offer a durable, rust-resistant surface ideal for curing, requiring minimal maintenance compared to cast iron alternatives like Lodge skillets. Their lighter weight and smooth finish promote even heat distribution, enhancing the seasoning process.

The factory-applied seasoning on carbon steel skillets helps prevent food from sticking and reduces the need for frequent re-seasoning. This makes them a preferred choice for chefs seeking efficiency and ease in maintaining a well-cured cooking surface.

Material Differences: Cast Iron vs Carbon Steel

Lodge skillets are made from cast iron, known for excellent heat retention and durability during curing processes. Pre-seasoned carbon steel skillets heat faster and are lighter, offering a different curing experience due to material properties.

- Heat Retention - Cast iron skillets retain heat longer, providing consistent temperature ideal for curing.

- Weight Difference - Carbon steel skillets are lighter and more responsive to temperature changes, affecting curing control.

- Surface Seasoning - Pre-seasoned carbon steel develops a natural non-stick layer quicker, impacting curing efficiency differently than cast iron.

Heat Retention and Distribution in Both Skillets

Which skillet offers better heat retention and distribution for curing? Lodge skillets, made from cast iron, provide excellent heat retention and even heat distribution, ideal for curing processes requiring consistent temperature. Pre-seasoned carbon steel skillets heat up faster but have slightly less heat retention, making them suitable for quick, high-heat curing tasks.

Curing Process: Step-by-Step Comparison

The curing process for a Lodge skillet begins with thorough washing to remove factory residue, followed by drying and coating with a thin layer of oil before heating it in the oven. Pre-seasoned carbon steel skillets typically arrive partially cured, but benefit from additional oiling and heating cycles to enhance the seasoning layer.

- Initial Cleaning - Lodge skillets require an initial scrub to remove protective wax, while pre-seasoned carbon steel skillets only need light cleaning.

- Oil Application - Both skillets need a thin, even coating of high smoke-point oil like flaxseed or vegetable oil to build a durable seasoning.

- Heating Process - Lodge skillets are cured at around 450degF for an hour, cooling before repeating, whereas carbon steel skillets benefit from multiple heat cycles at similar temperatures to strengthen the non-stick surface.

Following these curing steps ensures optimal rust resistance and improves non-stick performance for both Lodge and pre-seasoned carbon steel skillets.

Flavor Development: Lodge vs Carbon Steel

The Lodge skillet, made from cast iron, excels at developing rich, deep flavors due to its superior heat retention and even cooking surface that enhances the Maillard reaction during curing. Pre-seasoned carbon steel skillets heat up faster but may require more frequent seasoning to maintain their non-stick properties and flavor development capabilities.

Flavor development in Lodge skillets benefits from their porous surface, which absorbs and builds seasoning layers over time, intensifying the taste of cured foods. Carbon steel skillets offer a lighter, more responsive cooking experience, but their seasoning can be more delicate and less robust compared to Lodge's cast iron finish.

Durability and Longevity After Curing

Lodge skillets are made from seasoned cast iron, providing exceptional durability and a naturally non-stick surface that improves with each use, making them resistant to wear after curing. Pre-seasoned carbon steel skillets offer excellent heat conduction and develop a durable patina quickly, but they require more maintenance to prevent rust damage over time. Both skillets can last decades when properly cured and cared for, but Lodge's heavier cast iron typically provides greater longevity in heavy-duty cooking environments.

Maintenance and Ease of Recurring Cures

| The Lodge skillet, made from traditional cast iron, requires thorough drying and oiling after each use to maintain its seasoning and prevent rust, making recurring cures straightforward but slightly time-consuming. Pre-seasoned carbon steel skillets offer smoother surfaces and lighter weight, allowing quicker heating and easier maintenance through brief seasoning sessions between uses. While both need periodic curing, carbon steel skillets tend to require less frequent re-seasoning, enhancing ease of maintenance during regular use. |

Related Important Terms

Polymerization layer formation

Lodge skillet develops a durable polymerization layer through repeated seasoning processes, creating a natural non-stick surface that enhances flavor and protects the cast iron from rust. Pre-seasoned carbon steel skillets feature a factory-applied polymerized oil coating that provides an initial non-stick barrier but often requires further seasoning to build a robust, long-lasting polymerization layer for optimal curing and performance.

Micro-texture adherence

Lodge skillets feature a rougher micro-texture that enhances seasoning adherence and creates a resilient non-stick surface through repeated curing cycles. Pre-seasoned carbon steel skillets have a smoother micro-texture requiring multiple curing stages to build a durable, evenly bonded seasoning layer that improves cooking performance over time.

Silicon oil seasoning

Lodge skillets typically come pre-seasoned with vegetable oils, which can be less durable during curing compared to the silicon oil seasoning often applied to pre-seasoned carbon steel skillets. Silicon oil creates a harder, more resilient layer that enhances the skillet's non-stick properties and resistance to rust throughout the curing process.

Lodge Blacklock tri-seasoned finish

Lodge Blacklock tri-seasoned finish combines multiple layers of curing for enhanced non-stick performance and rust resistance compared to traditional pre-seasoned carbon steel skillets, which often require more frequent maintenance and re-seasoning to maintain effectiveness. The tri-seasoned surface provides a durable, naturally polymerized coating that improves heat distribution and long-term seasoning stability, ideal for consistent cooking results and easier care.

Carbon steel blueing

Carbon steel blueing enhances the curing process by forming a durable, rust-resistant layer on pre-seasoned skillets, unlike Lodge skillets which rely on factory seasoning that can wear off more quickly. This chemical treatment improves heat retention and ensures a longer-lasting non-stick surface critical for effective seasoning and maintenance.

Non-reactive oxide layer

The Lodge skillet's factory seasoning creates a thick, polymerized oil layer that offers strong non-reactive surface protection, while a pre-seasoned carbon steel skillet forms a thinner oxide layer that requires frequent curing to maintain its non-reactive properties. This non-reactive oxide layer in carbon steel skillets prevents rust and food from sticking when properly cured, but does not match the durability and chemical resistance of Lodge's cast iron seasoning.

Minimalist oil seasoning (MOS)

Lodge skillets feature factory-applied Minimalist Oil Seasoning (MOS) that provides a durable, non-stick surface requiring minimal maintenance and enhanced rust resistance. Pre-seasoned carbon steel skillets also utilize MOS techniques but often need additional curing layers to build a comparable protective patina and achieve optimal non-stick performance.

Quenched patina development

Lodge skillets develop a natural quenched patina more gradually due to their cast iron composition, which absorbs seasoning oil to form a durable, non-stick surface over time. Pre-seasoned carbon steel skillets benefit from a thinner, quicker-to-develop quenched patina that enhances heat responsiveness and smoothness, ideal for rapid seasoning cycles and maintenance.

Flaxseed oil polymer bonding

Flaxseed oil's high concentration of polyunsaturated fats enables superior polymer bonding during curing, creating a durable, natural non-stick seasoning on both Lodge cast iron skillets and pre-seasoned carbon steel skillets. Unlike factory pre-seasoned surfaces, hand-curing with flaxseed oil forms a harder, more resilient seasoning layer that enhances heat retention and rust resistance specific to the skillet's material composition.

Lodge skillet vs Pre-seasoned carbon steel skillet for curing. Infographic

cookingdiff.com

cookingdiff.com