Seasoned cast iron develops a natural non-stick surface through layers of polymerized fats and oils, providing durability and enhanced flavor with each use. Flaxseed oil polymerized cast iron creates a harder, more resilient seasoning due to its high concentration of polyunsaturated fats, resulting in a smoother, longer-lasting coating. Choosing between the two depends on whether you prioritize a quick, traditional build-up or a more durable, chemical polymerization for superior curing performance.

Table of Comparison

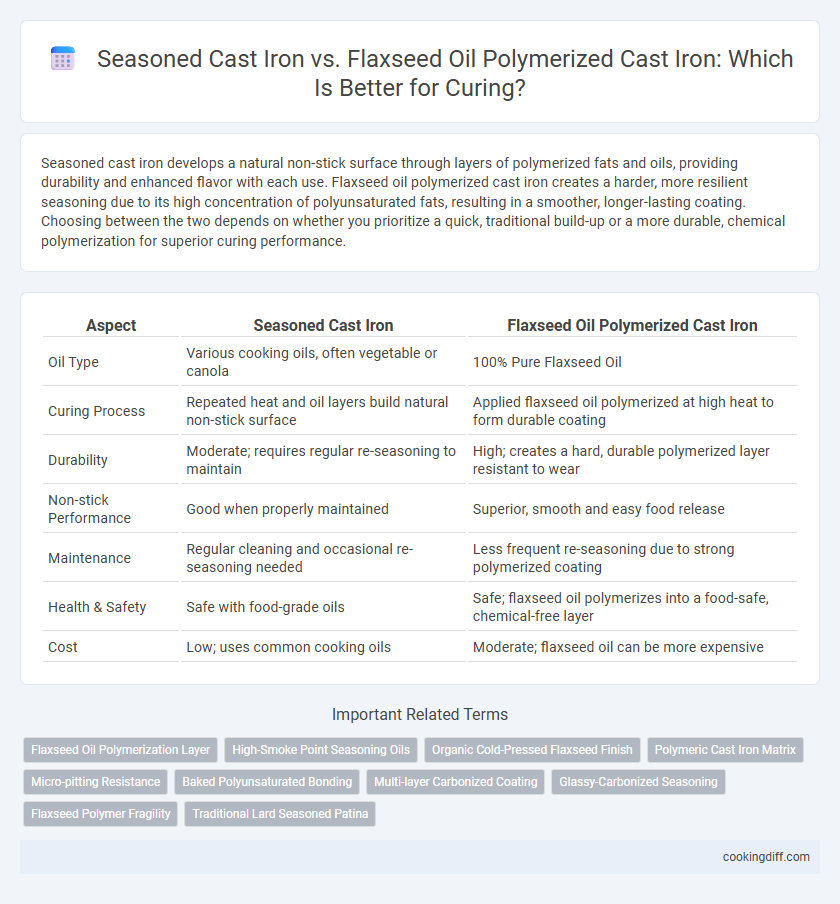

| Aspect | Seasoned Cast Iron | Flaxseed Oil Polymerized Cast Iron |

|---|---|---|

| Oil Type | Various cooking oils, often vegetable or canola | 100% Pure Flaxseed Oil |

| Curing Process | Repeated heat and oil layers build natural non-stick surface | Applied flaxseed oil polymerized at high heat to form durable coating |

| Durability | Moderate; requires regular re-seasoning to maintain | High; creates a hard, durable polymerized layer resistant to wear |

| Non-stick Performance | Good when properly maintained | Superior, smooth and easy food release |

| Maintenance | Regular cleaning and occasional re-seasoning needed | Less frequent re-seasoning due to strong polymerized coating |

| Health & Safety | Safe with food-grade oils | Safe; flaxseed oil polymerizes into a food-safe, chemical-free layer |

| Cost | Low; uses common cooking oils | Moderate; flaxseed oil can be more expensive |

Introduction to Cast Iron Curing Methods

Seasoned cast iron relies on the buildup of polymerized oils through repeated cooking and heating cycles, creating a natural non-stick surface. Flaxseed oil polymerized cast iron curing involves applying flaxseed oil and heating it to high temperatures, forming a durable, hard coating through chemical polymerization. Both methods enhance rust resistance and cooking performance but differ in application time and maintenance requirements.

What is a Seasoned Cast Iron?

A seasoned cast iron skillet is coated with a layer of polymerized oil that creates a natural, non-stick surface. This seasoning develops through repeated heating and oiling, which bonds oil molecules to the pan's surface, preventing rust and enhancing cooking performance.

Flaxseed oil polymerizes into a hard, durable coating that many consider excellent for seasoning due to its high concentration of polyunsaturated fats, which dry and form a tough layer. Seasoned cast iron requires regular maintenance, including proper cleaning and re-oiling, to preserve the seasoning. Compared to flaxseed oil seasoning, traditional methods may offer different durability and ease of application based on the type of oil used and heat applied.

Understanding Flaxseed Oil Polymerization

Flaxseed oil polymerizes through a drying process where oxygen molecules react with its unsaturated fatty acids, forming a durable, hard coating on cast iron surfaces. This natural polymerized layer enhances the non-stick properties and protects the cookware from rust, creating a seasoning that deepens with use.

Seasoned cast iron relies on the buildup of baked-on fats and oils, whereas flaxseed oil forms a more uniform and resilient polymerized film. The chemical transformation of flaxseed oil results in superior adhesion and longevity compared to traditional seasoning methods.

Key Differences: Seasoned vs Flaxseed Oil Cast Iron

Seasoned cast iron develops a natural, durable non-stick layer through repeated use and oil polymerization, while flaxseed oil polymerized cast iron involves a deliberate curing process using flaxseed oil to create a harder, more uniform seasoning layer. The flaxseed oil seasoning is prized for its high concentration of omega-3 fatty acids, which polymerize into a durable, smooth surface that's often superior in resilience.

- Durability - Flaxseed oil polymerized seasoning offers a harder, more durable coating compared to traditional seasoning from general cooking oils.

- Application Process - Seasoned cast iron develops seasoning gradually during regular cooking; flaxseed oil requires controlled high-heat polymerization for application.

- Surface Quality - Flaxseed oil creates a smoother, more uniform non-stick surface, while traditional seasoning can result in a more varied texture.

Longevity and Durability: Which Lasts Longer?

Seasoned cast iron develops a natural non-stick layer through repeated use and oil polymerization, providing moderate durability that requires regular maintenance to prevent rust and degradation. Flaxseed oil polymerized cast iron forms a harder, more resilient coating due to the high concentration of omega-3 fatty acids that polymerize into a durable, carbonized layer offering superior longevity.

Flaxseed oil cures into a tougher, more uniform seasoning that resists chipping and wear better than traditional seasoning methods, extending the lifespan of the cookware significantly. The enhanced polymerization process of flaxseed oil minimizes the need for frequent re-seasoning, making it a preferred choice for long-lasting cast iron protection.

Cooking Performance: Heat Retention and Non-Stick Qualities

| Type | Heat Retention | Non-Stick Qualities |

|---|---|---|

| Seasoned Cast Iron | Excellent heat retention ensures even cooking temperature maintenance. | Develops a natural non-stick surface over multiple uses, improving with time. |

| Flaxseed Oil Polymerized Cast Iron | High heat retention due to durable polymerized layer, enhancing cooking consistency. | Creates a hard, smooth, and highly non-stick surface faster than traditional seasoning methods. |

Maintenance and Re-Seasoning Needs

Seasoned cast iron requires regular maintenance and occasional re-seasoning to maintain its non-stick surface and prevent rust. Flaxseed oil polymerized cast iron creates a harder, more durable seasoning layer that reduces the frequency of re-seasoning and simplifies upkeep.

- Maintenance Frequency - Seasoned cast iron needs re-seasoning every few months depending on use and cleaning methods.

- Durability - Flaxseed oil polymerized seasoning forms a tough, resilient coating that lasts longer under heavy cooking conditions.

- Rust Prevention - Both types prevent rust effectively, but polymerized flaxseed oil provides stronger resistance to moisture and abrasion.

Choosing flaxseed oil polymerized seasoning often leads to lower maintenance efforts and extended seasoning longevity for cast iron cookware.

Safety and Health Considerations

Seasoned cast iron typically uses natural oils that can emit fewer volatile organic compounds (VOCs) during curing, reducing respiratory risks. Flaxseed oil polymerized cast iron involves high-temperature curing, which may release more fumes requiring adequate ventilation.

- Reduced VOC Emission - Seasoned cast iron emits fewer harmful fumes during curing, enhancing indoor air quality.

- High-Temperature Fume Exposure - Flaxseed oil polymerization produces more smoke and fumes, necessitating proper ventilation to protect respiratory health.

- Non-Toxic Finish - Both methods result in food-safe, chemical-free surfaces ideal for health-conscious cooking.

Popular Myths About Seasoning Cast Iron

Seasoned cast iron develops a natural non-stick surface through polymerized oils, but popular myths suggest flaxseed oil polymerized cast iron is superior, which is debated among professionals. Research indicates that while flaxseed oil creates a hard, durable coating, other oils like vegetable or canola also form effective seasoning layers when properly applied. The key to curing cast iron lies in consistent heating cycles and maintenance rather than the exclusive use of a specific oil type.

Related Important Terms

Flaxseed Oil Polymerization Layer

Flaxseed oil polymerizes into a durable, non-stick layer that enhances the corrosion resistance and heat retention of cast iron surfaces more effectively than traditional seasoning methods. This polymerized layer creates a harder, more resilient coating, reducing the need for frequent reseasoning and improving the overall longevity of the cookware.

High-Smoke Point Seasoning Oils

Seasoned cast iron traditionally uses oils with high smoke points like canola or grapeseed, which create durable polymerized layers that enhance non-stick properties and resist rust. Flaxseed oil, despite a lower smoke point, polymerizes into a harder, more resilient coating but requires precise temperature control during curing to avoid smoking and uneven seasoning.

Organic Cold-Pressed Flaxseed Finish

Seasoned cast iron develops a naturally non-stick, protective layer through repeated heating of oil and food residues, while an Organic Cold-Pressed Flaxseed Finish involves curing with polymerized flaxseed oil, creating a durable, hard coating that enhances rust resistance and longevity. The flaxseed oil's high concentration of polyunsaturated fats allows it to oxidize and form a robust, smooth patina, offering superior protection compared to traditional seasoning methods.

Polymeric Cast Iron Matrix

Polymeric cast iron matrix formed by flaxseed oil creates a durable, non-stick surface through polymerization, enhancing corrosion resistance and heat retention compared to traditional seasoned cast iron. This molecular cross-linking results in a harder, more resilient layer that outperforms the carbonized oil patina of seasoned cast iron in longevity and uniformity.

Micro-pitting Resistance

Seasoned cast iron develops a natural patina that provides moderate micro-pitting resistance by creating a protective barrier against moisture and acids. Flaxseed oil polymerized cast iron enhances micro-pitting resistance significantly through a durable, polymerized oil layer that seals microscopic pores and prevents corrosion more effectively than traditional seasoning methods.

Baked Polyunsaturated Bonding

Seasoned cast iron relies on baked polyunsaturated bonding formed by polymerized oils that create a durable, non-stick surface through repeated heating cycles. Flaxseed oil polymerized cast iron offers a superior seasoning layer due to its high content of polyunsaturated fats, which polymerize more effectively at high temperatures, resulting in a harder, more resilient coating that enhances the curing process.

Multi-layer Carbonized Coating

Seasoned cast iron develops a natural, multi-layer carbonized coating through repeated heating and oil polymerization, enhancing durability and non-stick properties. Flaxseed oil polymerized cast iron forms a harder, more uniform carbonized coating due to its high unsaturation, providing superior protection and longer-lasting seasoning.

Glassy-Carbonized Seasoning

Glassy-carbonized seasoning achieved through flaxseed oil polymerization forms a harder, more durable non-stick layer on cast iron compared to traditional seasoned cast iron, enhancing resistance to rust and wear. This carbon-rich, polymerized coating promotes superior heat retention and chemical stability, optimizing the curing process for long-lasting cookware performance.

Flaxseed Polymer Fragility

Flaxseed oil polymerized cast iron creates a thinner, harder seasoning layer that offers superior initial non-stick properties but is prone to flaking and fragility under thermal stress compared to the more durable, thicker seasoning developed with traditional seasoned cast iron. This fragility in flaxseed polymer can lead to frequent re-seasoning and maintenance due to its susceptibility to cracking and peeling from high-heat cycling and mechanical abrasion.

Seasoned cast iron vs flaxseed oil polymerized cast iron for curing. Infographic

cookingdiff.com

cookingdiff.com