Oiling stainless steel creates a thin protective layer that prevents rust and corrosion while maintaining the utensil's sleek surface and ease of cleaning. Beeswax seasoning, on the other hand, forms a natural, slightly hydrophobic barrier that enhances durability and adds a subtle, food-safe coating ideal for preserving wooden or metal curing tools. Choosing between oiling and beeswax depends on the desired finish, maintenance routine, and type of utensil being treated.

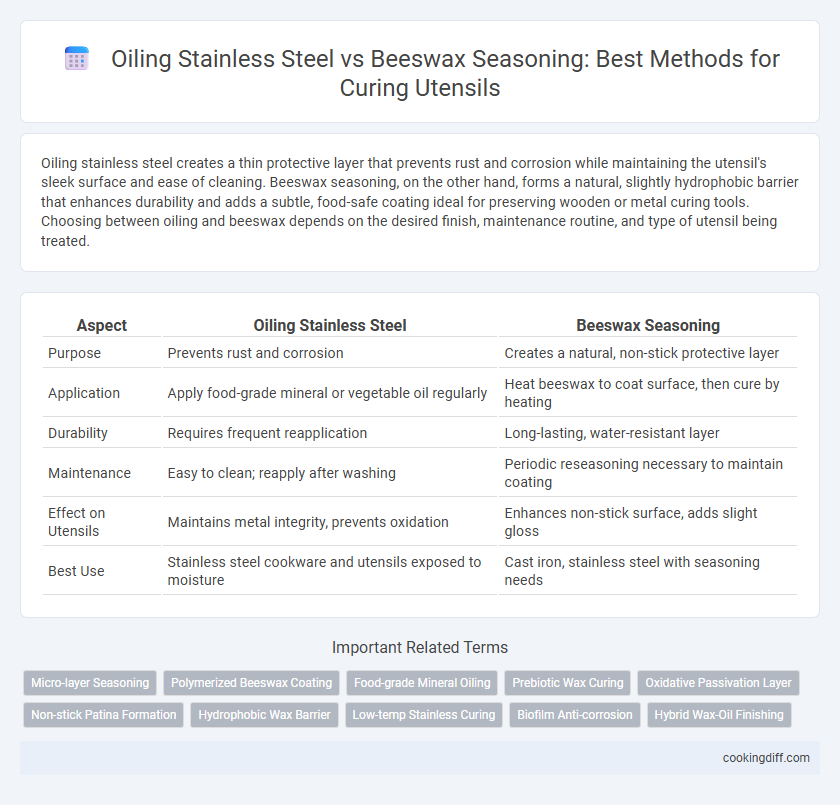

Table of Comparison

| Aspect | Oiling Stainless Steel | Beeswax Seasoning |

|---|---|---|

| Purpose | Prevents rust and corrosion | Creates a natural, non-stick protective layer |

| Application | Apply food-grade mineral or vegetable oil regularly | Heat beeswax to coat surface, then cure by heating |

| Durability | Requires frequent reapplication | Long-lasting, water-resistant layer |

| Maintenance | Easy to clean; reapply after washing | Periodic reseasoning necessary to maintain coating |

| Effect on Utensils | Maintains metal integrity, prevents oxidation | Enhances non-stick surface, adds slight gloss |

| Best Use | Stainless steel cookware and utensils exposed to moisture | Cast iron, stainless steel with seasoning needs |

Introduction to Utensil Curing: Purpose and Benefits

Oiling stainless steel utensils enhances corrosion resistance and prevents rust formation, extending the lifespan of kitchen tools. The application of food-safe oils creates a protective barrier that minimizes moisture and contaminants on metal surfaces.

Beeswax seasoning forms a durable, natural coating that improves non-stick properties while safeguarding stainless steel from oxidation. This curing method also adds a subtle sheen and reinforces the utensil's surface against wear and tear over time.

Understanding Stainless Steel: Properties and Challenges

Stainless steel is prized for its corrosion resistance and durability, making it a popular material for kitchen utensils. However, its non-porous surface can make seasoning and curing more challenging compared to other materials.

Oiling stainless steel helps create a thin protective layer that prevents rust and reduces food sticking, although it doesn't penetrate the metal. Beeswax seasoning, by contrast, offers a natural, water-resistant coating that can enhance the utensil's surface over time. Both methods aim to improve utensil longevity, but beeswax provides a more sustainable and eco-friendly option for maintaining stainless steel cookware.

What is Oiling? Overview and Common Oils Used

Oiling stainless steel utensils involves applying a thin layer of food-safe oils to protect the surface from rust and corrosion. Common oils used for this purpose include mineral oil, grapeseed oil, and flaxseed oil, chosen for their non-toxic properties and resistance to rancidity. This method enhances durability and maintains the utensil's smooth finish without altering its natural appearance.

Beeswax Seasoning: Natural Approach to Utensil Curing

Beeswax seasoning offers a natural approach to curing stainless steel utensils by creating a protective, water-resistant layer that enhances durability and prevents rust. This method utilizes beeswax's inherent antibacterial properties, promoting a safer and more hygienic surface.

Unlike oiling, which can require frequent reapplication to maintain effectiveness, beeswax forms a longer-lasting coating that withstands regular use and washing. The natural composition of beeswax also reduces the risk of chemical leaching, making it an eco-friendly choice for utensil maintenance.

Application Methods: Oiling vs Beeswax Techniques

Oiling stainless steel utensils involves applying a thin layer of food-grade oil to create a protective barrier against rust and corrosion. Beeswax seasoning forms a durable, water-resistant coating by melting and bonding beeswax to the utensil's surface through heat application.

- Oiling Method - Typically uses mineral or vegetable oils applied with a cloth for ease of maintenance.

- Beeswax Technique - Requires warming the beeswax until it melts, then evenly spreading it to achieve a hardened finish after cooling.

- Durability and Reapplication - Oil needs more frequent reapplication, while beeswax seasoning lasts longer but involves a more involved process.

Choosing between oiling and beeswax seasoning depends on desired longevity and ease of upkeep for stainless steel utensils.

Durability and Longevity of Seasoned Coatings

Oiling stainless steel creates a thin, protective layer that resists rust and corrosion, enhancing the durability of utensils during frequent use. Beeswax seasoning forms a thicker, natural barrier that seals pores and prevents moisture ingress, extending the longevity of the seasoning under consistent heat exposure. The combination of oil and beeswax often yields the most resilient coating, balancing immediate protection with long-term wear resistance.

Food Safety Considerations: Oil vs Beeswax

Which is safer for curing utensils, oiling stainless steel or using beeswax seasoning? Oiling stainless steel with food-grade oils like mineral or vegetable oil creates a non-toxic barrier that prevents rust and contamination without introducing allergens. Beeswax seasoning offers natural antimicrobial properties but may pose risks for those with bee product allergies and requires careful application to avoid buildup and bacterial growth.

Maintenance: Cleaning and Re-seasoning Tips

Oiling stainless steel utensils requires regular cleaning and reapplication to maintain a protective barrier against rust and wear. Beeswax seasoning creates a natural, water-resistant coating that enhances utensil longevity with less frequent maintenance.

- Oiling Frequency - Apply food-safe oil after each wash to prevent oxidation and maintain a smooth surface.

- Beeswax Durability - Re-season beeswax coatings every few months to restore water repellency and prevent cracking.

- Cleaning Methods - Use mild soap and warm water for both treatments, avoiding abrasive scrubbers to preserve the curing layer.

Eco-Friendliness and Sustainability Factors

| Oiling stainless steel utensils involves applying mineral or vegetable oils that are biodegradable and non-toxic, enhancing durability and reducing waste by prolonging utensil life. Beeswax seasoning uses a natural, renewable resource harvested sustainably, forming a protective, eco-friendly coating that prevents rust without chemicals. Both methods contribute to sustainability, but beeswax offers a fully natural, compostable layer, while oiling prioritizes maintenance with minimal environmental impact depending on oil source. |

Related Important Terms

Micro-layer Seasoning

Oiling stainless steel creates a micro-layer that penetrates pores, enhancing corrosion resistance and food safety by preventing metal ion transfer. Beeswax seasoning forms a durable hydrophobic barrier through polymerized lipids, offering superior protection against moisture and oxidation during utensil curing.

Polymerized Beeswax Coating

Polymerized beeswax coating provides a durable, non-toxic barrier on stainless steel utensils that enhances corrosion resistance and maintains a natural, food-safe surface. Unlike oiling, which may require frequent reapplication and can harbor bacteria, beeswax seasoning creates a long-lasting, hydrophobic layer that improves utensil longevity and performance during food preparation.

Food-grade Mineral Oiling

Food-grade mineral oil penetrates stainless steel utensils to create a protective, non-toxic barrier that prevents rust and maintains a smooth surface ideal for food preparation. Unlike beeswax seasoning, mineral oil does not harden or become sticky over time, ensuring easier maintenance and prolonged utensil longevity.

Prebiotic Wax Curing

Prebiotic wax curing, such as using beeswax, creates a natural, antimicrobial barrier on stainless steel utensils that enhances durability while maintaining food safety. Unlike oiling, which can leave residues prone to rancidity and microbial growth, prebiotic wax provides long-lasting protection and promotes a healthier, self-sustaining microbial environment.

Oxidative Passivation Layer

Oiling stainless steel forms a thin, protective film that enhances the oxidative passivation layer, preventing rust and corrosion more effectively than beeswax seasoning which primarily provides a superficial barrier. The oxidative passivation layer on stainless steel is chemically stabilized by oil treatments, ensuring long-term durability and resistance to oxidative damage during curing.

Non-stick Patina Formation

Oiling stainless steel utensils creates a thin, durable non-stick patina by polymerizing oils at high heat, enhancing surface protection and food release. Beeswax seasoning forms a softer, more natural coating that fills microscopic surface pores, promoting moderate non-stick properties but requiring more frequent reapplication to maintain effectiveness.

Hydrophobic Wax Barrier

Oiling stainless steel creates a hydrophobic wax barrier that repels water and prevents rust, enhancing the longevity and cleanliness of the utensil's surface. Beeswax seasoning similarly forms a natural hydrophobic coating, providing resistance to moisture while adding antimicrobial properties that further protect stainless steel during curing and use.

Low-temp Stainless Curing

Low-temp stainless curing relies on oiling stainless steel utensils to create a durable, non-stick surface resistant to rust and corrosion without compromising the metal's integrity; unlike beeswax seasoning, oiling forms a thin, polymerized layer that withstands lower curing temperatures and frequent use. This method enhances longevity and cleanliness in culinary environments by maintaining the steel's natural properties while providing effective protection during daily cooking routines.

Biofilm Anti-corrosion

Oiling stainless steel creates a thin protective biofilm that prevents oxidation and corrosion by repelling moisture and contaminants, enhancing the utensil's durability. Beeswax seasoning forms a natural barrier with hydrophobic properties, reducing biofilm formation and providing sustained corrosion resistance through its antimicrobial effects.

Oiling stainless steel vs beeswax seasoning for curing utensils. Infographic

cookingdiff.com

cookingdiff.com