Uncoated cast iron grills retain natural seasoning that enhances flavor but may cause uneven curing due to inconsistent heat distribution and potential sticking. Plasma-treated grills offer a non-stick, durable surface that promotes even heat flow and hygienic curing without chemical coatings. Choosing plasma-treated grills improves consistency and cleanliness in the curing process compared to traditional uncoated cast iron.

Table of Comparison

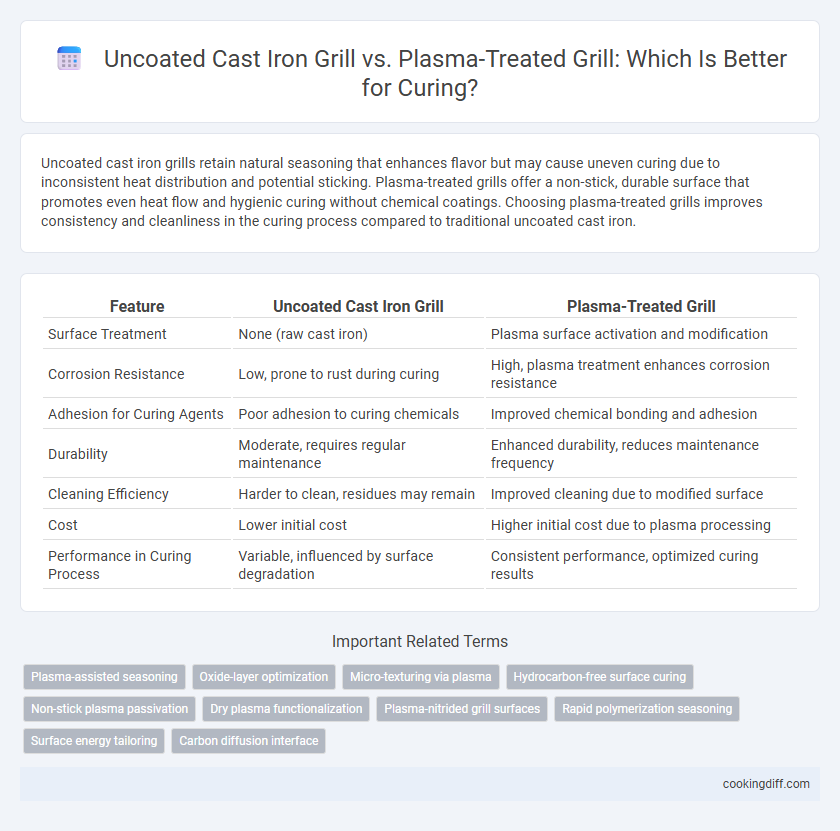

| Feature | Uncoated Cast Iron Grill | Plasma-Treated Grill |

|---|---|---|

| Surface Treatment | None (raw cast iron) | Plasma surface activation and modification |

| Corrosion Resistance | Low, prone to rust during curing | High, plasma treatment enhances corrosion resistance |

| Adhesion for Curing Agents | Poor adhesion to curing chemicals | Improved chemical bonding and adhesion |

| Durability | Moderate, requires regular maintenance | Enhanced durability, reduces maintenance frequency |

| Cleaning Efficiency | Harder to clean, residues may remain | Improved cleaning due to modified surface |

| Cost | Lower initial cost | Higher initial cost due to plasma processing |

| Performance in Curing Process | Variable, influenced by surface degradation | Consistent performance, optimized curing results |

Introduction to Curing: Importance in Cooking

| Uncoated cast iron grills provide excellent heat retention and natural seasoning, which enhances flavor during the curing process by creating a stable cooking environment. |

| Plasma-treated grills feature a modified surface that improves non-stick properties and resistance to corrosion, allowing for more precise temperature control and uniform heat distribution during curing. |

| The choice between uncoated cast iron and plasma-treated grills directly affects curing consistency, flavor development, and overall cooking efficiency, crucial factors in achieving optimal meat texture and taste. |

Uncoated Cast Iron Grills: Key Features

Uncoated cast iron grills offer superior heat retention and distribution, essential for consistent curing processes. Their porous surface enhances seasoning over time, improving non-stick properties without chemical coatings.

These grills resist high temperatures and mechanical wear, providing durability crucial for prolonged curing cycles. Maintenance involves regular seasoning to prevent rust, ensuring optimal curing quality.

Plasma-Treated Grills: Innovative Advancements

Plasma-treated grills for curing exhibit superior surface energy and enhanced adhesion properties compared to uncoated cast iron grills, leading to more uniform curing results. This technological innovation reduces curing time and improves the durability of the grill surface by minimizing oxidation and contamination.

The plasma treatment process modifies the grill surface at a molecular level, increasing hydrophilicity and enabling better interaction with curing agents. This results in consistent heat distribution and prevents sticking, which is common with traditional uncoated cast iron grills. As a result, plasma-treated grills optimize curing efficiency, reduce maintenance, and extend operational lifespan in industrial applications.

How Curing Works on Uncoated Cast Iron

Uncoated cast iron grills rely on their porous surface to retain heat and create an even cooking environment, which is essential for curing processes. The natural seasoning on the cast iron interacts with the meat, enhancing flavor development while allowing moisture to evaporate gradually. This slow moisture release helps achieve a tender, evenly cured product without the risk of sticking or burning.

Curing Performance of Plasma-Treated Grills

Plasma-treated grills significantly enhance curing performance compared to uncoated cast iron grills by promoting superior heat distribution and surface activation. This improved efficiency results in more uniform curing and reduced processing times.

- Enhanced Heat Transfer - Plasma treatment modifies the grill surface to optimize thermal conductivity, ensuring even heat spread during the curing process.

- Surface Activation - The plasma-treated surface increases chemical reactivity, improving adhesion and uniformity of the cured layer.

- Reduced Processing Time - Due to better heat and surface properties, plasma-treated grills accelerate curing cycles, increasing throughput and energy efficiency.

Flavor Development: Cast Iron vs Plasma-Treated

How does flavor development differ between uncoated cast iron grills and plasma-treated grills during curing? Uncoated cast iron grills enhance flavor through natural seasoning layers that build up over time, contributing to a rich, smoky taste. Plasma-treated grills offer a more uniform surface that prevents food from sticking, allowing for precise flavor infusion without chemical residues.

Maintenance and Longevity: A Comparative Analysis

Uncoated cast iron grills require regular seasoning to prevent rust and preserve their surface integrity, leading to more frequent maintenance compared to plasma-treated grills. Plasma-treated grills exhibit enhanced corrosion resistance and surface hardness, significantly extending their longevity and reducing upkeep costs. This advanced treatment ensures consistent performance under high-heat curing conditions, making plasma-treated grills a more durable investment.

Health and Safety Considerations in Curing

Uncoated cast iron grills may retain residues and contaminants that pose health risks during curing, increasing the chance of bacterial growth. Cleaning challenges lead to potential cross-contamination, impacting food safety standards and worker hygiene.

Plasma-treated grills offer superior surface sterilization and antimicrobial properties, significantly reducing harmful pathogens during the curing process. Their enhanced durability and resistance to corrosion contribute to safer handling and reduced exposure to toxic residues, ensuring a healthier curing environment.

Cost and Accessibility: Which Grill is Worth It?

Uncoated cast iron grills offer affordability and widespread availability, making them a cost-effective option for curing enthusiasts. Plasma-treated grills, while more expensive, provide enhanced durability and performance for specialized curing needs.

- Cost Efficiency - Uncoated cast iron grills are significantly cheaper, reducing initial investment cost.

- Accessibility - Cast iron grills are widely available in most hardware and kitchen stores worldwide.

- Durability and Performance - Plasma-treated grills resist corrosion and improve curing quality but come with higher price tags.

Related Important Terms

Plasma-assisted seasoning

Plasma-treated grills enhance the curing process by creating a uniform oxide layer that improves the adhesion of seasoning on cast iron surfaces, resulting in superior non-stick properties and corrosion resistance compared to uncoated cast iron grills. Plasma-assisted seasoning accelerates the formation of a durable, chemically bonded layer that ensures long-lasting protection and reduces maintenance frequency.

Oxide-layer optimization

Uncoated cast iron grills develop a natural oxide layer that enhances flavor retention but may lack uniformity, impacting curing consistency. Plasma-treated grills create a precisely controlled oxide layer that improves surface durability and promotes even heat distribution, optimizing the curing process.

Micro-texturing via plasma

Plasma-treated grills enhance curing by micro-texturing the surface, increasing adhesion and heat transfer compared to uncoated cast iron grills. This micro-texturing process creates a more uniform cooking surface, improving flavor development and reducing sticking during the curing process.

Hydrocarbon-free surface curing

Uncoated cast iron grills often retain hydrocarbons that can interfere with curing processes by introducing contaminants, whereas plasma-treated grills provide a hydrocarbon-free surface that enhances chemical bonding and promotes uniform curing. The plasma treatment modifies the grill surface at a molecular level, increasing surface energy and ensuring optimal adhesion without organic residue.

Non-stick plasma passivation

Non-stick plasma passivation on plasma-treated grills creates a durable, corrosion-resistant surface that improves curing efficiency by preventing food adhesion and allowing consistent heat distribution. Uncoated cast iron grills, while durable, tend to retain residues and require frequent seasoning, which can interfere with curing uniformity and increase maintenance.

Dry plasma functionalization

Dry plasma functionalization enhances the surface energy and wettability of cast iron grills without adding coatings, promoting uniform curing and preventing food adhesion. Unlike uncoated cast iron, plasma-treated grills improve durability and cleaning efficiency by modifying the grill's surface chemistry at the molecular level.

Plasma-nitrided grill surfaces

Plasma-nitrided grill surfaces offer enhanced wear resistance and superior hardness compared to uncoated cast iron grills, significantly improving curing performance by reducing surface degradation and contamination risks. This advanced plasma treatment promotes uniform heat distribution and longevity, resulting in more consistent curing outcomes and reduced maintenance needs.

Rapid polymerization seasoning

Rapid polymerization seasoning on plasma-treated grills significantly enhances surface durability and reduces curing time compared to uncoated cast iron grills, which often display uneven seasoning and slower polymerization rates. Plasma treatment promotes a uniform oxide layer that accelerates polymer bonding, resulting in a more resilient, non-stick surface optimal for consistent curing performance.

Surface energy tailoring

Plasma-treated grills for curing exhibit significantly enhanced surface energy compared to uncoated cast iron grills, promoting superior adhesion and uniform curing of coatings. This tailored surface energy improves wetting properties, leading to consistent curing performance and reducing defects such as blistering or peeling.

Uncoated cast iron grill vs Plasma-treated grill for curing. Infographic

cookingdiff.com

cookingdiff.com