Steel wok patina develops through repeated heating and cooking, forming a natural non-stick surface ideal for high-heat stir-frying and enhancing flavor over time. Beeswax seasoning creates a protective barrier that prevents rust and adds a subtle coating, but it may not develop the rich, layered patina that improves with extensive use. For curing a steel wok, the patina formation is generally more effective in providing durability and enhanced cooking performance compared to beeswax seasoning.

Table of Comparison

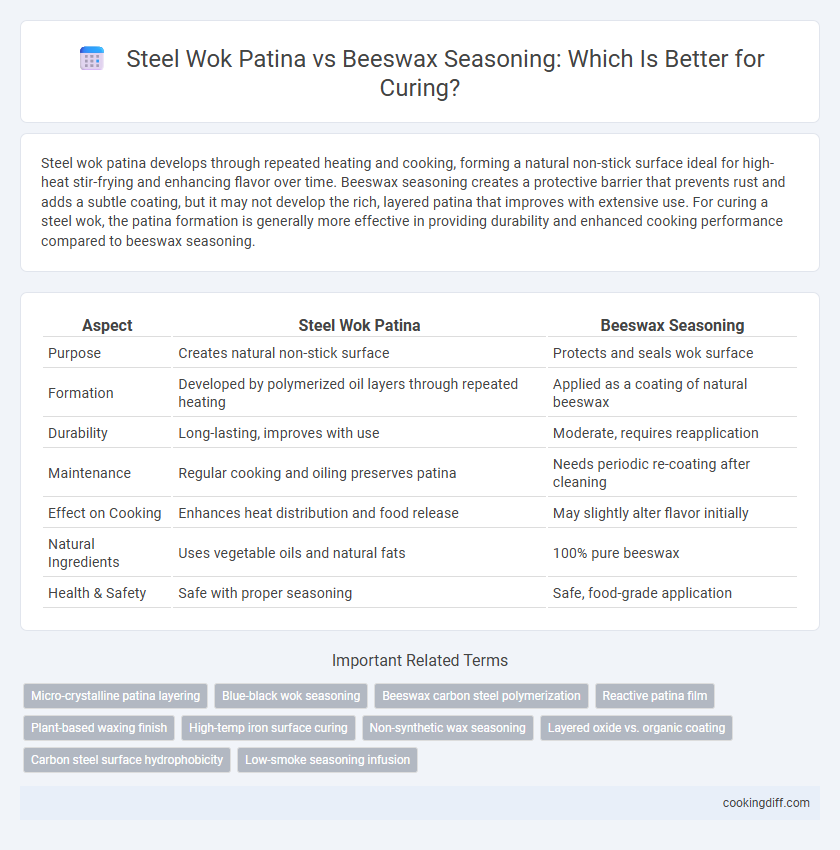

| Aspect | Steel Wok Patina | Beeswax Seasoning |

|---|---|---|

| Purpose | Creates natural non-stick surface | Protects and seals wok surface |

| Formation | Developed by polymerized oil layers through repeated heating | Applied as a coating of natural beeswax |

| Durability | Long-lasting, improves with use | Moderate, requires reapplication |

| Maintenance | Regular cooking and oiling preserves patina | Needs periodic re-coating after cleaning |

| Effect on Cooking | Enhances heat distribution and food release | May slightly alter flavor initially |

| Natural Ingredients | Uses vegetable oils and natural fats | 100% pure beeswax |

| Health & Safety | Safe with proper seasoning | Safe, food-grade application |

Introduction to Curing Steel Woks

Curing a steel wok involves creating a protective layer to prevent rust and enhance cooking performance. Patina forms naturally through repeated heating and oiling, developing a durable non-stick surface. Beeswax seasoning offers an alternative by applying a natural coating that seals the metal and aids in initial rust prevention.

What is Patina on a Steel Wok?

A patina on a steel wok is a natural, thin layer of oxidation that forms on the surface during repeated heating and cooking, enhancing its non-stick properties. This protective coating develops over time and improves with use, unlike beeswax seasoning which provides an initial, artificial barrier.

- Patina Formation - It occurs through polymerization of oils and natural oxidation, creating a durable, non-stick surface.

- Heat Resistance - Patina withstands high cooking temperatures without melting or burning away.

- Maintenance - Proper care involves avoiding soap and moisture to preserve and deepen the patina over time.

Understanding Beeswax Seasoning

What makes beeswax seasoning effective for curing steel woks? Beeswax creates a durable, water-resistant patina that protects the wok surface from rust and enhances non-stick properties. Unlike traditional oil seasoning, beeswax forms a smoother, longer-lasting coating that improves with regular use.

Chemical Processes: Patina vs. Beeswax Seasoning

The chemical process of patina formation on a steel wok involves oxidation that creates a protective, polymerized layer of iron oxide, enhancing the cookware's non-stick properties. Beeswax seasoning relies on the thermal decomposition and polymerization of bee-derived waxes to form a hydrophobic barrier that prevents rust and food adhesion.

- Patina Formation - This process oxidizes the steel surface, producing a durable, naturally bonded coating that improves with use and heat exposure.

- Beeswax Polymerization - Heating beeswax causes it to break down and polymerize into a resilient, water-resistant film sealing the wok's surface.

- Durability Comparison - Patina tends to be more heat-resistant and long-lasting, while beeswax seasoning may require more frequent reapplication for effective protection.

Advantages of Patina for Steel Wok Curing

Patina formation on a steel wok enhances its natural non-stick properties and provides a durable, heat-resistant surface that improves with use. This layer of polymerized oils protects the steel from rust and corrosion, ensuring a longer lifespan for the wok.

Unlike beeswax seasoning, patina develops through repeated heating and oil application, creating a more integral and resilient coating. It offers superior heat retention and even cooking, critical for high-temperature stir-frying. The organic patina also imparts subtle flavor nuances that beeswax cannot replicate, making it the preferred choice for traditional steel wok curing.

Benefits of Beeswax as a Seasoning Agent

Beeswax as a seasoning agent creates a durable, non-stick patina on steel woks, enhancing heat retention and distribution for superior cooking performance. Its natural antimicrobial properties inhibit rust and prolong the wok's lifespan without imparting any chemical odors or flavors. Unlike traditional oil seasoning, beeswax provides a smoother, more resilient coating that requires less frequent maintenance and improves the overall cooking experience.

Durability Comparison: Patina vs. Beeswax Coating

Steel wok patina forms a durable, natural oxide layer that strengthens with continued use, resisting rust and enhancing flavor over time. Beeswax seasoning provides a temporary protective coating that seals but can wear off quickly under high heat or frequent washing.

- Patina Durability - The oxide layer creates a long-lasting, self-healing surface that improves with cooking.

- Beeswax Longevity - Beeswax coatings need regular reapplication as heat and moisture degrade the wax.

- Heat Resistance - Patina withstands high temperatures better than beeswax, which may melt or burn.

For long-term protection and flavor development, patina curing is more durable than beeswax seasoning.

Flavor Impact: Steel Wok Patina vs. Beeswax

| Flavor Impact of Steel Wok Patina | Steel wok patina develops through repeated high-heat cooking, creating a natural non-stick layer that imparts subtle smoky and umami notes to dishes, enhancing depth and complexity in stir-fries. |

| Flavor Impact of Beeswax Seasoning | Beeswax seasoning forms a protective coating that preserves the cookware's integrity without altering food flavor significantly, maintaining a clean and neutral taste ideal for delicate recipes. |

| Comparative Flavor Profile | Steel wok patina actively contributes a rich, seasoned flavor profile enhancing food complexity, whereas beeswax seasoning offers functional protection with minimal sensory influence, making patina preferable for enhancing taste. |

Step-by-Step Guide: Achieving Patina and Beeswax Seasoning

Begin by heating the steel wok over medium-high heat until it reaches a blue-gray color, indicating the formation of a natural patina that enhances non-stick properties and rust resistance. Wipe the surface with a paper towel to remove any residue before applying a thin layer of vegetable oil to seal the patina layer.

For beeswax seasoning, melt beeswax and dip a clean cloth to evenly coat the cooled wok surface, creating a protective barrier that adds durability and a smooth finish. Let the beeswax cool and harden, then buff the surface gently to achieve a stable seasoning layer that complements the patina's protective qualities.

Related Important Terms

Micro-crystalline patina layering

Steel wok patina develops through repeated heating and cooking, forming a durable micro-crystalline layer that enhances non-stick properties and resistance to rust. Beeswax seasoning creates a protective film but lacks the chemical bonding and micro-crystalline structure of a traditional patina, making it less effective for long-term curing and durability.

Blue-black wok seasoning

Blue-black wok seasoning creates a durable, heat-resistant patina by undergoing molecular oxidation, which enhances non-stick properties and prevents rust more effectively than beeswax seasoning. Beeswax provides a temporary protective layer but lacks the chemical bonding that the high-temperature curing of steel woks achieves for long-lasting performance.

Beeswax carbon steel polymerization

Beeswax seasoning on a steel wok forms a natural polymerized layer through carbonization that enhances non-stick properties and provides long-lasting protection against rust. Unlike traditional patina, beeswax creates a durable, hydrophobic polymer film that seals the carbon steel surface, improving durability and food release during cooking.

Reactive patina film

Steel wok patina forms a reactive oxide layer through high-heat seasoning that enhances non-stick properties and flavor development by interacting with acidic ingredients, unlike beeswax seasoning which mainly provides a protective barrier without chemical reactivity. The reactive patina film improves durability and seasoning depth, promoting optimal rust resistance and natural food release over time.

Plant-based waxing finish

Plant-based waxing finishes for curing steel woks create a natural, food-safe patina that enhances non-stick properties while preventing rust, offering an eco-friendly alternative to beeswax seasoning. These finishes lock in oil molecules better, promoting a durable, sustainable coating that withstands high heat and frequent use without harmful residues.

High-temp iron surface curing

High-temp iron surface curing with steel wok patina forms a durable, naturally polymerized layer that enhances non-stick properties and rust resistance under intense heat, while beeswax seasoning provides a softer, protective coating primarily effective at lower temperatures but prone to burning off under high heat. Steel wok patina's polymerized iron oxide layer withstands thermal cycling better, promoting long-term cooking performance and cookware longevity in high-temperature applications.

Non-synthetic wax seasoning

Steel wok patina forms a durable, non-stick surface through polymerized oil layers, enhancing heat retention and flavor development, while beeswax seasoning creates a natural, non-synthetic wax coating that offers water resistance and food-safe protection without chemical additives. Opting for beeswax seasoning ensures an eco-friendly, chemical-free curing method that preserves the wok's integrity and promotes sustainable maintenance.

Layered oxide vs. organic coating

Steel wok patina forms a durable layered oxide coating that enhances non-stick properties and resists rust through chemical bonding with the metal surface. Beeswax seasoning creates an organic coating that offers initial water resistance and flavor protection but requires frequent reapplication to maintain effectiveness.

Carbon steel surface hydrophobicity

Steel wok patina enhances carbon steel surface hydrophobicity by creating a thin layer of polymerized oils that repel water and prevent rust, fostering natural non-stick properties. Beeswax seasoning adds a protective hydrophobic coating but may degrade faster under high heat, making patina a more durable solution for maintaining water resistance on carbon steel cookware.

Steel wok patina vs beeswax seasoning for curing. Infographic

cookingdiff.com

cookingdiff.com