Grill flame seasoning enhances pan curing by imparting a rich, smoky flavor and creating a durable, non-stick surface through direct high heat exposure. Infrared torch seasoning offers precise temperature control and rapid heat application, reducing the risk of overheating and uneven seasoning on pans. Both methods improve pan durability, but grill flames provide deeper carbonization, while infrared torches allow for more consistent, controlled seasoning layers.

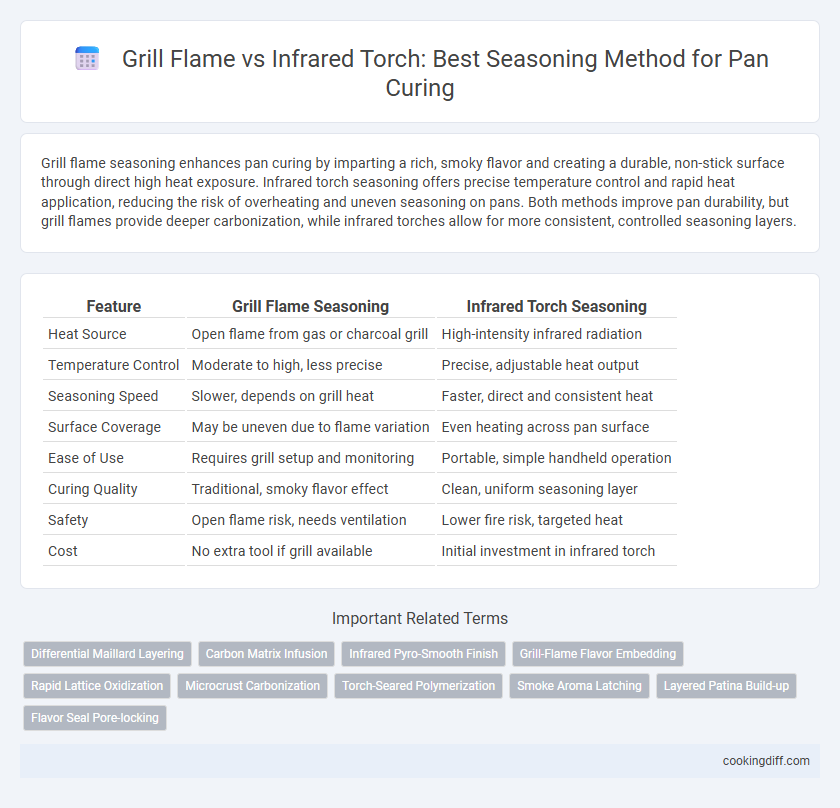

Table of Comparison

| Feature | Grill Flame Seasoning | Infrared Torch Seasoning |

|---|---|---|

| Heat Source | Open flame from gas or charcoal grill | High-intensity infrared radiation |

| Temperature Control | Moderate to high, less precise | Precise, adjustable heat output |

| Seasoning Speed | Slower, depends on grill heat | Faster, direct and consistent heat |

| Surface Coverage | May be uneven due to flame variation | Even heating across pan surface |

| Ease of Use | Requires grill setup and monitoring | Portable, simple handheld operation |

| Curing Quality | Traditional, smoky flavor effect | Clean, uniform seasoning layer |

| Safety | Open flame risk, needs ventilation | Lower fire risk, targeted heat |

| Cost | No extra tool if grill available | Initial investment in infrared torch |

Introduction to Pan Curing Methods

Grill flame seasoning and infrared torch seasoning are two popular methods for curing pans, each offering distinct heat application techniques. Grill flame seasoning uses direct open flame to evenly distribute heat, promoting a natural polymerization of oils on the pan surface. Infrared torch seasoning provides concentrated, high-temperature heat, enabling faster curing and precise control over the pan coating process.

What is Grill Flame Seasoning?

Grill flame seasoning is a technique that uses direct flame from a grill to cure and enhance the non-stick properties of a pan. This method involves exposing the pan surface to high heat, which helps to create a durable, carbonized layer of oil that prevents rust and improves cooking performance.

Using grill flame seasoning offers the advantage of even heat distribution and faster curing compared to traditional stovetop methods. The intense flame quickly polymerizes the oil, forming a hard, protective coating that is resistant to food sticking and corrosion. This technique is especially effective for cast iron and carbon steel cookware, ensuring long-lasting seasoning with minimal effort.

What is Infrared Torch Seasoning?

Infrared torch seasoning uses infrared radiation to evenly heat the pan surface for curing, promoting better oil polymerization. This method provides precise temperature control and reduces the risk of hot spots compared to traditional grill flame seasoning.

- Infrared radiation - Delivers consistent heat that penetrates the pan surface uniformly.

- Temperature control - Allows for accurate regulation preventing overheating or burning during seasoning.

- Enhanced curing quality - Results in a durable, non-stick seasoning layer that improves pan longevity.

Heat Distribution: Grill Flame vs Infrared Torch

Grill flame seasoning distributes heat unevenly, creating hotspots that can lead to inconsistent pan curing and potential warping. Infrared torch seasoning offers uniform heat distribution, ensuring a smooth, even cure across the entire pan surface.

Consistent heat from an infrared torch enhances the polymerization of oils, resulting in a durable, non-stick seasoning layer. In contrast, the grill flame's fluctuating temperatures may cause patchy seasoning and require multiple applications for optimal results.

Flavor Development: Comparing Both Techniques

Grill flame seasoning imparts a smoky, charred flavor that enhances the depth of the pan's seasoning layer. Infrared torch seasoning provides a more controlled heat source, resulting in a subtle, even flavor development without overpowering smokiness.

- Grill Flame Seasoning - Creates complex smoky notes by direct flame contact, enriching the pan's flavor profile.

- Infrared Torch Seasoning - Uses consistent radiant heat to develop seasoning evenly, preserving the pan's original taste nuances.

- Flavor Intensity - Grill flame produces bolder, smokier flavors while infrared torch offers more delicate, refined seasoning effects.

Choosing between these techniques depends on desired flavor intensity and seasoning control for optimal pan curing.

Ease of Use and Accessibility

Grill flame seasoning offers a straightforward method for pan curing, relying on the familiar propane grill setup commonly found in many households. Infrared torch seasoning, while effective, demands a specific tool that may not be as readily accessible or intuitive for beginners.

- Grill flame seasoning is easy to perform - It uses standard propane grills, providing a simple and accessible option for most users.

- Infrared torch seasoning requires specialized equipment - The infrared torch is less common and may require an additional purchase, impacting accessibility.

- Grill flame seasoning is user-friendly - Familiar grilling techniques make it easier for individuals without extensive curing experience to achieve consistent results.

Safety Considerations for Each Method

Grill flame seasoning exposes pans to direct, open flames, increasing the risk of flare-ups and burns if not carefully monitored. Infrared torch seasoning provides precise heat control and reduces the likelihood of accidental fires, making it a safer option for indoor use. Proper ventilation and protective gear are essential for both methods to ensure safe curing practices.

Time Efficiency in Pan Curing

Which method offers better time efficiency for pan curing: Grill Flame Seasoning or Infrared Torch Seasoning? Infrared Torch Seasoning significantly reduces curing time by delivering consistent, intense heat that quickly polymerizes the seasoning layer. Grill Flame Seasoning often requires longer, uneven heating periods, resulting in extended curing cycles and less uniform seasoning layers.

Best Results: Which Method to Choose?

Grill flame seasoning imparts a smoky flavor and creates a natural non-stick surface by evenly distributing heat through direct flame exposure, ideal for cast iron pans. Infrared torch seasoning offers precise temperature control and faster heat penetration, reducing the risk of uneven curing or overheating delicate cookware.

For best results, choose grill flame seasoning when seeking a traditional, depth-enhanced seasoning layer with robust flavor. Opt for infrared torch seasoning to achieve consistent seasoning with minimal effort and exact heat management, especially useful in controlled indoor environments.

Related Important Terms

Differential Maillard Layering

Grill flame seasoning creates a robust Maillard layer through direct high-heat contact, enhancing flavor depth via caramelization and smoke infusion, while infrared torch seasoning delivers precise, uniform heat promoting controlled Maillard reactions and consistent crust development. The differential Maillard layering achieved by grill flames often results in a more complex, smoky profile, whereas infrared torches favor even browning with minimized flare-ups and enhanced surface texture uniformity.

Carbon Matrix Infusion

Grill flame seasoning creates a carbon matrix infusion by exposing the pan's surface to high, uneven heat, generating a thicker, more textured seasoning layer ideal for durability and non-stick performance. Infrared torch seasoning provides precise, consistent heat that promotes uniform carbon matrix formation, resulting in a smoother, evenly infused seasoning with enhanced resistance to flaking and wear.

Infrared Pyro-Smooth Finish

Infrared torch seasoning provides an even, high-temperature heat that ensures a consistent, durable pyro-smooth finish on pans, significantly reducing surface irregularities compared to traditional grill flame seasoning. This method enhances the pan's non-stick properties and longevity by creating a uniform carbon layer that resists chipping and promotes superior seasoning adherence.

Grill-Flame Flavor Embedding

Grill-flame seasoning penetrates the pan surface by exposing it directly to high, uneven flames, embedding a smoky, charred flavor profile that enhances the seasoning's complexity and depth. This method promotes the formation of robust polymerized oil layers, which adhere strongly and impart a distinct, grilled aroma that infrared torch seasoning cannot replicate due to its concentrated, uniform heat application.

Rapid Lattice Oxidization

Grill flame seasoning promotes rapid lattice oxidization through direct high-heat exposure, creating a durable, non-stick coating by quickly bonding oils to the pan's surface. Infrared torch seasoning offers precise, controlled heat application, enabling uniform lattice oxidization with minimal risk of overheating and enhancing the pan's curing consistency.

Microcrust Carbonization

Grill flame seasoning enhances microcrust carbonization by providing uneven, high-temperature flames that create a robust, flavorful crust on pans. Infrared torch seasoning delivers precise, consistent heat, promoting a more uniform microcrust development and reducing the risk of hot spots or overheating during pan curing.

Torch-Seared Polymerization

Torch-seared polymerization during pan curing using an infrared torch creates a more uniform and controlled seasoning layer by precisely heating oil molecules to form durable polymer bonds. In contrast, grill flame seasoning often results in uneven heat distribution, leading to inconsistent polymerization and a less resilient seasoning surface.

Smoke Aroma Latching

Grill flame seasoning infuses pans with a rich, smoky aroma that deeply latches onto the surface, enhancing food flavor through natural combustion byproducts. Infrared torch seasoning produces a cleaner, more controlled heat that limits smoke aroma adhesion, resulting in a milder, less complex seasoning layer.

Layered Patina Build-up

Grill flame seasoning creates a textured, layered patina by repeatedly exposing the pan's surface to intense, uneven heat, fostering carbonized oil buildup that enhances non-stick properties and rust resistance. Infrared torch seasoning offers precise, high-temperature control that promotes uniform polymerization of oils, resulting in a smoother, more consistent patina ideal for achieving a durable and visually appealing finish.

Grill Flame Seasoning vs Infrared Torch Seasoning for pan curing. Infographic

cookingdiff.com

cookingdiff.com