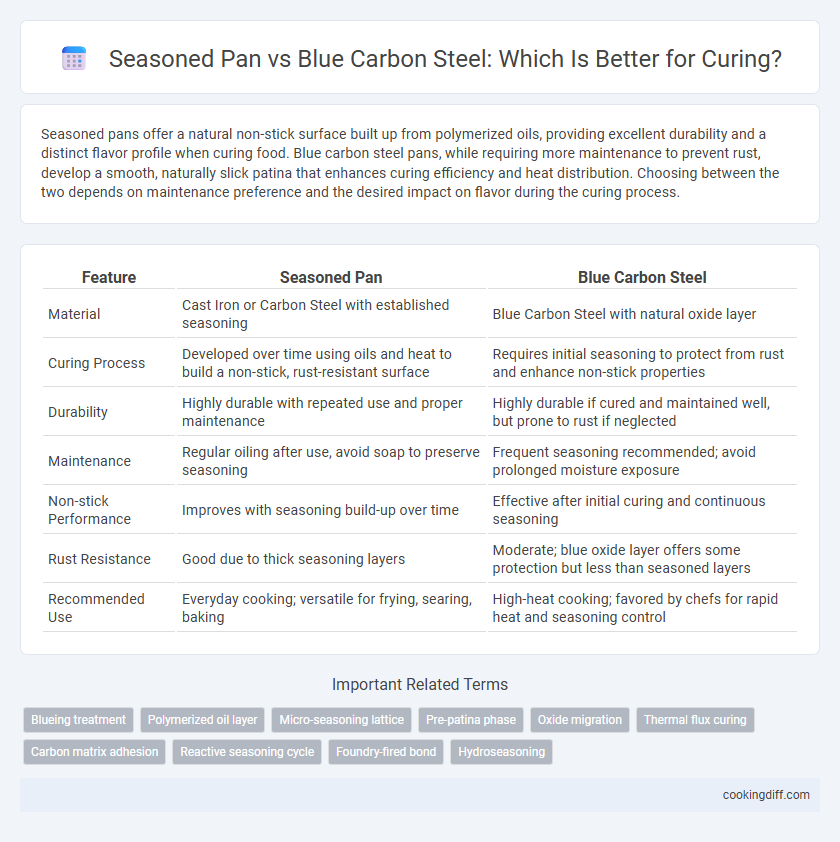

Seasoned pans offer a natural non-stick surface built up from polymerized oils, providing excellent durability and a distinct flavor profile when curing food. Blue carbon steel pans, while requiring more maintenance to prevent rust, develop a smooth, naturally slick patina that enhances curing efficiency and heat distribution. Choosing between the two depends on maintenance preference and the desired impact on flavor during the curing process.

Table of Comparison

| Feature | Seasoned Pan | Blue Carbon Steel |

|---|---|---|

| Material | Cast Iron or Carbon Steel with established seasoning | Blue Carbon Steel with natural oxide layer |

| Curing Process | Developed over time using oils and heat to build a non-stick, rust-resistant surface | Requires initial seasoning to protect from rust and enhance non-stick properties |

| Durability | Highly durable with repeated use and proper maintenance | Highly durable if cured and maintained well, but prone to rust if neglected |

| Maintenance | Regular oiling after use, avoid soap to preserve seasoning | Frequent seasoning recommended; avoid prolonged moisture exposure |

| Non-stick Performance | Improves with seasoning build-up over time | Effective after initial curing and continuous seasoning |

| Rust Resistance | Good due to thick seasoning layers | Moderate; blue oxide layer offers some protection but less than seasoned layers |

| Recommended Use | Everyday cooking; versatile for frying, searing, baking | High-heat cooking; favored by chefs for rapid heat and seasoning control |

Understanding Seasoned Pans and Blue Carbon Steel

Seasoned pans develop a natural non-stick coating through polymerized oils that protect the surface and enhance cooking performance. Blue carbon steel, treated through thermal oxidation, forms a durable, rust-resistant layer that improves heat retention and seasoning quality. Both materials benefit from proper curing techniques that maintain their protective patina and extend cookware longevity.

What is Curing in Cooking?

| Curing in cooking refers to the process of seasoning or treating cookware to create a natural, non-stick, and rust-resistant surface. Seasoned pans develop a protective oil layer through repeated heating and oil application, enhancing flavor and cooking performance over time. Blue carbon steel pans require curing to build a durable patina that improves with use, offering superior heat retention and corrosion resistance compared to unseasoned cookware. |

Composition: Seasoned Pan vs Blue Carbon Steel

Seasoned pans typically consist of cast iron with a polymerized oil layer forming the seasoning, while blue carbon steel is composed of high-carbon steel treated to develop a protective blue oxide coating. The different materials influence how each surface interacts with oils and heat during curing, impacting both durability and non-stick properties.

- Cast Iron Composition - Seasoned pans are primarily cast iron, offering excellent heat retention but requiring regular oil seasoning to maintain a non-stick surface.

- Blue Carbon Steel Alloy - Blue carbon steel is a high-carbon steel alloy that develops a thin, corrosion-resistant blue oxide layer during curing.

- Surface Reactivity - The polymerized seasoning on cast iron creates a stable non-stick layer, whereas the blue oxide on carbon steel provides initial rust resistance but also benefits from seasoning for optimal performance.

Choosing between seasoned cast iron and blue carbon steel for curing depends on desired maintenance and heat conduction characteristics.

Heat Retention and Distribution Compared

Seasoned cast iron pans excel in heat retention, maintaining consistent temperatures ideal for slow cooking and searing. Blue carbon steel pans offer superior heat distribution, allowing for quick, even heating across the surface, which is perfect for tasks requiring precision temperature control. Choosing between the two depends on whether consistent heat retention or rapid, uniform heat distribution is prioritized during the curing and cooking process.

Non-Stick Qualities After Curing

How do the non-stick qualities of seasoned pans compare to blue carbon steel after curing? Seasoned pans develop a natural, polymerized oil layer that enhances non-stick performance over time. Blue carbon steel, when properly cured, offers a smooth surface with excellent non-stick properties but requires regular maintenance to preserve its coating.

Maintenance and Re-Curing Differences

Seasoned pans develop a natural non-stick layer through repeated oil polymerization, requiring gentle cleaning and occasional re-oiling to maintain their seasoning. Blue carbon steel pans, while forming a protective patina, demand more frequent re-curing due to their higher susceptibility to rust and oxidation.

Maintenance of seasoned pans involves avoiding abrasive scrubbers and using mild detergents to preserve the seasoning layer. Blue carbon steel requires thorough drying and immediate oil application after use to prevent rust, with re-curing necessary whenever the patina wears thin.

Flavor Development in Seasoned and Blue Carbon Steel Pans

Seasoned pans develop a natural non-stick surface through polymerized oils, which enhances flavor by infusing dishes with subtle, rich notes from previous cooking sessions. The seasoned layer also provides a mellow, well-rounded taste profile, ideal for slow-cooked and seared recipes.

Blue carbon steel pans offer superior heat retention and responsiveness, promoting Maillard reactions that intensify flavor complexity. Their unique seasoning process forms a durable patina, which contributes to a slightly smoky, robust taste that improves with use.

Durability and Longevity in Cured Pans

Seasoned pans develop a natural non-stick surface through polymerized oils, enhancing durability with regular maintenance. Blue carbon steel offers superior hardness and resistance to scratching, contributing to its longevity during curing and use.

Seasoned pans require consistent upkeep to maintain their protective seasoning layer, which can improve durability over time but may wear down with improper care. Blue carbon steel resists rust and deformation better, making it ideal for long-term longevity in a cured state. Both materials benefit from proper curing techniques to optimize their lifespan and performance.

Best Applications: When to Use Each Pan

Seasoned pans excel in slow-cooked, low-temperature dishes allowing the natural non-stick surface to enhance flavors. Blue carbon steel pans are ideal for high-heat applications such as searing or stir-frying due to their rapid heat conduction and durability.

- Seasoned Pans for Slow Cooking - Perfect for braising and simmering where gentle heat preserves seasoning layers.

- Blue Carbon Steel for Searing - Best used for quick, high-temperature cooking that requires rapid heat response.

- Maintenance Consideration - Seasoned pans require regular upkeep to maintain non-stick quality, while blue carbon steel develops a natural patina with use.

Related Important Terms

Blueing treatment

Blue carbon steel pans undergo a bluing treatment that creates a thin oxide layer, enhancing corrosion resistance and providing a natural non-stick surface ideal for curing. Seasoned pans rely on polymerized oils for protection, but blueing offers a more durable, chemically bonded finish that improves longevity and performance during curing processes.

Polymerized oil layer

The blue carbon steel pan develops a more durable polymerized oil layer during curing, enhancing its natural non-stick properties and corrosion resistance compared to the thinner, less resilient seasoning on traditional cast iron pans. This polymerized layer forms a hard, smooth surface through repeated heating cycles, providing superior performance and longevity in cookware maintenance.

Micro-seasoning lattice

Seasoned pans develop a micro-seasoning lattice through polymerized oils that create a non-stick, rust-resistant surface essential for curing processes. Blue carbon steel forms a denser, more uniform micro-seasoning lattice due to its higher carbon content, offering superior durability and enhanced resistance to corrosion compared to traditional seasoned pans.

Pre-patina phase

During the pre-patina phase, a seasoned pan provides a natural non-stick surface formed by polymerized oils, whereas blue carbon steel develops a stable oxide layer through controlled heating that enhances corrosion resistance and flavor development. Blue carbon steel's pre-patina phase requires precise curing temperatures to build a uniform, durable patina that outperforms traditional seasoning in longevity and resilience.

Oxide migration

Seasoned pans develop a stable polymerized oil layer that limits oxide migration, enhancing durability during curing. In contrast, blue carbon steel relies on a surface oxide layer that undergoes controlled oxide migration, improving corrosion resistance but requiring regular maintenance to sustain its curing benefits.

Thermal flux curing

Seasoned pans offer enhanced thermal retention and even heat distribution, enabling consistent thermal flux curing by maintaining steady temperatures during the process. Blue carbon steel pans, with their superior heat conductivity and rapid response to temperature changes, provide precise control over thermal flux curing, allowing for faster and more efficient heat transfer.

Carbon matrix adhesion

Seasoned pans develop a natural carbon matrix layer through polymerized oils that enhance adhesion and oxidation resistance, while blue carbon steel forms a chemically bonded oxide layer providing a durable surface for curing. The carbon matrix on seasoned pans offers superior non-stick properties and gradual reinforcement with use, whereas blue carbon steel's oxide layer demands controlled curing to maintain adhesion and prevent flaking.

Reactive seasoning cycle

Seasoned pans develop a natural non-stick layer through polymerized oils, enhancing durability and food release with each reactive seasoning cycle, while blue carbon steel undergoes a chemical transformation forming a dark patina that offers superior rust resistance and improved seasoning longevity. The reactive seasoning cycle on blue carbon steel involves repeated heating and oil application that creates a robust, corrosion-resistant surface ideal for high-heat cooking and prolonged use.

Foundry-fired bond

Seasoned pans develop a natural, polymerized oil layer that enhances food release, while blue carbon steel used in curing forms a durable foundry-fired bond through heat treatment, providing superior rust resistance and longevity. This foundry-fired bond on blue carbon steel better withstands thermal shock and abrasive cleaning, making it ideal for high-usage curing applications.

Seasoned pan vs blue carbon steel for curing. Infographic

cookingdiff.com

cookingdiff.com