Hand-rubbed seasoning allows for deeper flavor penetration by physically massaging the cure into the meat, enhancing texture and taste. Electrostatic sprayed seasoning offers a more uniform and efficient application, creating a consistent coating while reducing waste. Choosing between these methods depends on desired flavor intensity and production scale in curing pet products.

Table of Comparison

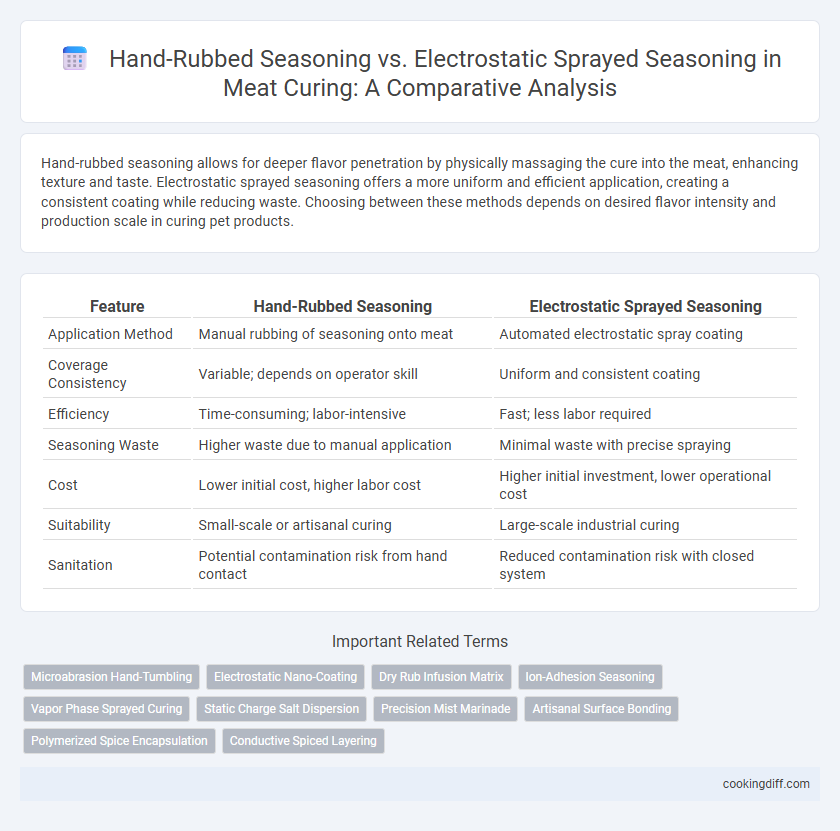

| Feature | Hand-Rubbed Seasoning | Electrostatic Sprayed Seasoning |

|---|---|---|

| Application Method | Manual rubbing of seasoning onto meat | Automated electrostatic spray coating |

| Coverage Consistency | Variable; depends on operator skill | Uniform and consistent coating |

| Efficiency | Time-consuming; labor-intensive | Fast; less labor required |

| Seasoning Waste | Higher waste due to manual application | Minimal waste with precise spraying |

| Cost | Lower initial cost, higher labor cost | Higher initial investment, lower operational cost |

| Suitability | Small-scale or artisanal curing | Large-scale industrial curing |

| Sanitation | Potential contamination risk from hand contact | Reduced contamination risk with closed system |

Introduction to Seasoning Methods in Curing

Hand-rubbed seasoning and electrostatic sprayed seasoning represent two primary methods used in the curing process to enhance flavor and preservation. Each technique impacts seasoning distribution and product quality differently, influencing the final cured product's texture and taste.

- Hand-rubbed seasoning - This traditional method involves manually applying spices and salts, allowing for thorough surface coverage and penetration into the meat.

- Electrostatic sprayed seasoning - Utilizes charged particles to evenly coat the meat, improving efficiency and reducing seasoning waste compared to manual application.

- Impact on curing - The chosen seasoning method affects curing time, flavor uniformity, and microbial control, essential factors for product consistency and safety.

What is Hand-Rubbed Seasoning?

| Hand-Rubbed Seasoning | Hand-rubbed seasoning involves manually applying a blend of spices and curing agents directly onto the meat surface, ensuring even distribution and enhanced flavor penetration. This traditional method allows precise control over seasoning intensity and texture, promoting better absorption during the curing process. It is widely preferred for artisanal and small-batch curing due to its customized application and authenticity. |

Electrostatic Sprayed Seasoning Explained

Electrostatic sprayed seasoning utilizes charged particles to evenly distribute curing agents across meat surfaces, enhancing penetration and uniformity compared to traditional hand-rubbed methods. This technique improves product consistency and reduces processing time in large-scale meat curing operations.

The electrostatic charge attracts seasoning particles to the meat, minimizing waste and ensuring thorough coverage, which is crucial for flavor and preservation. This method also supports automation and hygiene standards, making it preferred in industrial curing environments.

Flavor Penetration: Hand-Rubbed vs Electrostatic

Hand-rubbed seasoning allows for deeper flavor penetration by physically embedding spices into the meat's surface, enhancing taste intensity. Electrostatic sprayed seasoning uses charged particles to evenly coat the meat, promoting uniform flavor distribution but typically results in more superficial flavor integration. Both methods impact curing efficiency, with hand-rubbing favored for robust flavor absorption and electrostatic spraying preferred for consistency and speed.

Consistency and Coverage of Seasoning

Hand-rubbed seasoning offers uneven coverage, leading to inconsistent flavor distribution across the cured product, which can affect taste and appearance. Electrostatic sprayed seasoning ensures uniform application by using charged particles that adhere evenly to the meat's surface, improving both consistency and coverage. This method reduces seasoning waste and enhances overall product quality by delivering precise, controlled flavor application throughout the curing process.

Impact on Curing Time and Efficiency

Electrostatic sprayed seasoning accelerates curing time by ensuring uniform and rapid adhesion of curing agents on meat surfaces. Hand-rubbed seasoning, while traditional, often results in inconsistent coverage, leading to longer and less efficient curing processes.

- Electrostatic spraying improves curing uniformity - This method provides an even distribution of seasoning, reducing curing time by enhancing agent penetration.

- Hand-rubbed seasoning leads to variability - Manual application may cause uneven coverage, prolonging curing duration and reducing process efficiency.

- Efficiency gains with electrostatic methods - Automated spraying reduces labor and increases throughput, optimizing overall curing operations.

Equipment and Skill Requirements

What are the equipment and skill requirements for hand-rubbed seasoning versus electrostatic sprayed seasoning in curing? Hand-rubbed seasoning demands minimal equipment, relying on manual tools and experienced labor to ensure even application and penetration. Electrostatic sprayed seasoning requires specialized spray systems and trained operators to achieve a uniform coat efficiently, reducing labor intensity and improving consistency.

Cost Analysis: Traditional vs Modern Methods

Hand-rubbed seasoning in curing typically incurs higher labor costs due to the manual application process, affecting overall production expenses. Electrostatic sprayed seasoning reduces labor time and seasoning waste by delivering a more uniform coating, resulting in lower operational costs.

Equipment investment for electrostatic spraying involves significant upfront costs but offers scalability and efficiency gains that decrease per-unit seasoning expenses over time. Traditional hand-rubbing methods remain cost-effective for small batches but exhibit higher variability and slower throughput compared to modern electrostatic systems.

Safety and Sanitation Considerations

Hand-rubbed seasoning for curing allows for precise application but requires strict adherence to hygiene protocols to prevent cross-contamination. Electrostatic sprayed seasoning offers a more uniform coat, reducing manual contact and minimizing bacterial transfer risks in curing environments.

Electrostatic spraying systems incorporate enclosed equipment that can be regularly sanitized, enhancing overall food safety during the curing process. Hand-rubbing demands thorough handwashing and glove use to maintain sanitation, increasing labor dependencies and potential human error. Both methods necessitate compliance with FDA food safety standards and HACCP guidelines to ensure product safety and quality.

Related Important Terms

Microabrasion Hand-Tumbling

Hand-rubbed seasoning enables precise microabrasion through manual hand-tumbling, enhancing flavor absorption and surface texture by gently breaking down the meat's outer layer. In contrast, electrostatic sprayed seasoning offers uniform coating but lacks the mechanical abrasion benefits critical for deeper cure penetration and improved seasoning adherence.

Electrostatic Nano-Coating

Electrostatic nano-coating offers a uniform, highly efficient curing process by ensuring even distribution of seasoning particles on surfaces, significantly enhancing adhesion and durability compared to traditional hand-rubbed seasoning. This cutting-edge technology reduces curing time and material waste while improving antimicrobial properties, making it ideal for advanced food preservation and industrial applications.

Dry Rub Infusion Matrix

Hand-rubbed seasoning creates a rich Dry Rub Infusion Matrix by physically embedding spices into the meat's surface, enhancing flavor absorption through direct contact and pressure. Electrostatic sprayed seasoning forms a more uniform coating by using charged particles to evenly distribute spices, but may result in a less integrated infusion compared to the tactile penetration achieved by hand-rubbing.

Ion-Adhesion Seasoning

Hand-rubbed seasoning relies on manual application, creating uneven coverage and less effective ion adhesion, whereas electrostatic sprayed seasoning uses charged particles to uniformly coat surfaces, enhancing ion adhesion for superior curing results. The ion-adhesion seasoning in electrostatic spraying promotes deeper penetration of curing agents, improving flavor development and preservation compared to traditional hand-rubbing methods.

Vapor Phase Sprayed Curing

Hand-rubbed seasoning relies on manual application, often resulting in uneven cure distribution and inconsistent flavor intensity, whereas electrostatic sprayed seasoning, particularly vapor phase sprayed curing, enhances uniformity by generating charged droplets that adhere more efficiently to meat surfaces. Vapor phase sprayed curing improves penetration and coverage of curing agents, reducing processing time and increasing product shelf life through precise and consistent application.

Static Charge Salt Dispersion

Hand-rubbed seasoning relies on manual application, often resulting in uneven salt dispersion and inconsistent curing due to limited surface contact. Electrostatic sprayed seasoning utilizes static charge technology to uniformly disperse salt particles, enhancing adhesion and ensuring a more consistent and efficient curing process.

Precision Mist Marinade

Hand-rubbed seasoning relies on manual application, resulting in uneven coverage and inconsistent curing, whereas electrostatic sprayed seasoning using Precision Mist Marinade ensures uniform distribution and enhanced adhesion of curing agents on meat surfaces. This method improves flavor penetration, reduces seasoning waste, and accelerates the curing process by maximizing surface contact and absorption.

Artisanal Surface Bonding

Hand-rubbed seasoning creates artisanal surface bonding through manual application, enhancing flavor absorption and texture consistency by allowing spices to adhere intimately to the meat's surface. Electrostatic sprayed seasoning achieves uniform coverage with efficient adhesion by using electrical charges to bind particles evenly, but may lack the nuanced, textured bonding characteristic of hand-rubbed methods.

Polymerized Spice Encapsulation

Polymerized spice encapsulation enhances flavor retention and uniformity in hand-rubbed seasoning by creating a strong adhesive layer on the meat surface, while electrostatic sprayed seasoning achieves more precise and efficient distribution through charged particle attraction. The encapsulation process in hand-rubbing promotes deeper flavor infusion by allowing the polymerized spices to bond effectively with the meat proteins, contrasting with the surface-level coating typically seen in electrostatic spray applications.

Hand-rubbed seasoning vs electrostatic sprayed seasoning for curing. Infographic

cookingdiff.com

cookingdiff.com