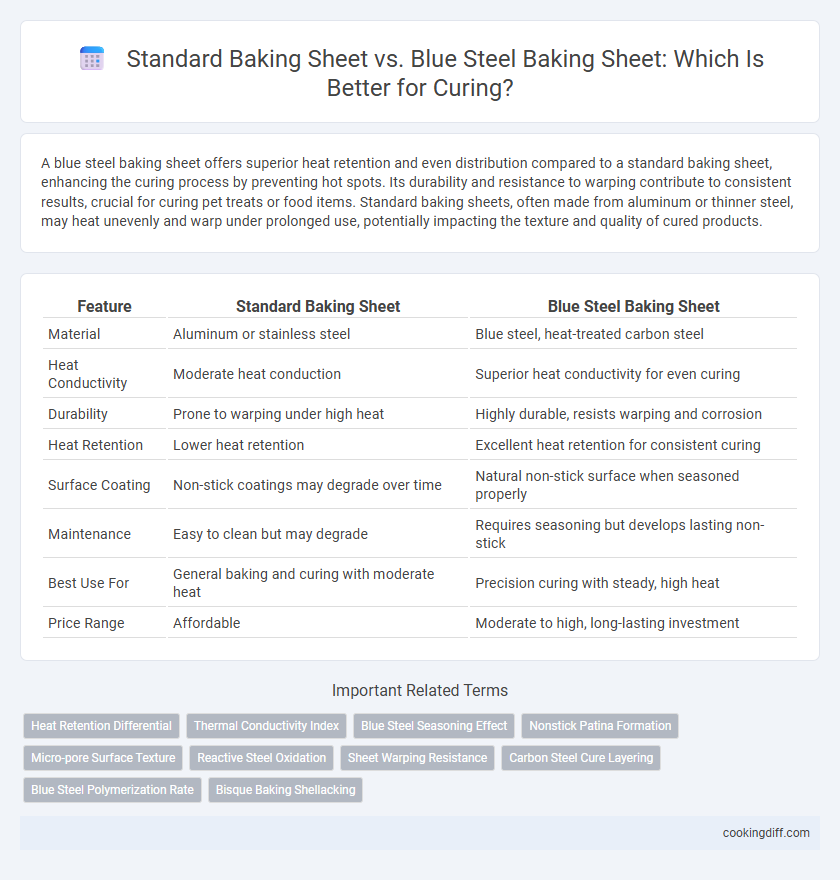

A blue steel baking sheet offers superior heat retention and even distribution compared to a standard baking sheet, enhancing the curing process by preventing hot spots. Its durability and resistance to warping contribute to consistent results, crucial for curing pet treats or food items. Standard baking sheets, often made from aluminum or thinner steel, may heat unevenly and warp under prolonged use, potentially impacting the texture and quality of cured products.

Table of Comparison

| Feature | Standard Baking Sheet | Blue Steel Baking Sheet |

|---|---|---|

| Material | Aluminum or stainless steel | Blue steel, heat-treated carbon steel |

| Heat Conductivity | Moderate heat conduction | Superior heat conductivity for even curing |

| Durability | Prone to warping under high heat | Highly durable, resists warping and corrosion |

| Heat Retention | Lower heat retention | Excellent heat retention for consistent curing |

| Surface Coating | Non-stick coatings may degrade over time | Natural non-stick surface when seasoned properly |

| Maintenance | Easy to clean but may degrade | Requires seasoning but develops lasting non-stick |

| Best Use For | General baking and curing with moderate heat | Precision curing with steady, high heat |

| Price Range | Affordable | Moderate to high, long-lasting investment |

Introduction to Curing: The Role of Baking Sheets

Curing processes benefit from precise temperature control and even heat distribution, making the choice of baking sheet critical. Standard baking sheets, typically made from aluminum, offer fast heat conduction but may cause uneven curing due to hot spots. Blue steel baking sheets provide superior heat retention and uniform surface temperature, enhancing consistent curing results in food preparation.

What Is a Standard Baking Sheet?

A standard baking sheet is typically made from aluminum or aluminized steel, featuring a flat surface with raised edges to prevent spills during curing processes. It offers even heat distribution, making it suitable for various baking and curing applications at home or in professional kitchens.

While standard baking sheets are versatile and affordable, they may not retain heat as effectively as blue steel baking sheets. This can impact curing times, especially for temperature-sensitive ingredients.

Understanding Blue Steel Baking Sheets

Blue steel baking sheets offer superior heat retention and quicker recovery times compared to standard baking sheets, making them ideal for curing processes requiring consistent temperatures. Their durability and resistance to warping enhance performance during repeated use.

- Superior Heat Retention - Blue steel maintains steady heat longer, ensuring even curing across the surface.

- Durability - These sheets resist warping and damage under high temperatures, extending their lifespan.

- Improved Heat Recovery - Blue steel baking sheets quickly return to optimal temperature after loading, supporting consistent curing results.

Heat Conductivity: Standard vs Blue Steel

Blue steel baking sheets offer superior heat conductivity compared to standard baking sheets, resulting in more even curing. Standard baking sheets often have lower thermal conductivity, causing slower and less uniform heat distribution.

- Blue Steel Heat Conductivity - Blue steel typically conducts heat faster and more evenly than the aluminum or nonstick layers used in standard sheets.

- Standard Baking Sheet Limitations - Lower heat conductivity can lead to hotspots and uneven curing, affecting product quality.

- Impact on Curing Efficiency - Faster heat transfer with blue steel sheets reduces curing time and enhances consistency.

Durability and Longevity Comparison

Standard baking sheets, typically made from aluminum or aluminized steel, offer moderate durability and may warp or corrode over time when exposed to high heat and moisture during curing. Blue steel baking sheets, composed of carbon steel with a protective blue oxide coating, exhibit superior resistance to rust and warping, extending their lifespan significantly in curing applications.

While standard baking sheets often require replacement after repeated use due to degradation, blue steel sheets maintain structural integrity and performance over many curing cycles. Their enhanced durability makes blue steel baking sheets a cost-effective choice for long-term use in both commercial and home curing processes.

Impact on Food Flavor and Texture During Curing

Standard baking sheets, typically made from aluminum or stainless steel, provide even heat distribution but can sometimes cause slight moisture loss, subtly affecting the texture of cured foods. Blue steel baking sheets enhance heat retention and promote more consistent moisture retention, resulting in a more tender texture and intensified flavor during the curing process. The superior thermal conductivity of blue steel sheets helps maintain optimal curing conditions, preserving the food's natural aroma and depth of taste.

Maintenance and Care: Blue Steel vs Standard

Blue steel baking sheets require regular seasoning to maintain their non-stick surface and prevent rust, unlike standard baking sheets that often have a protective coating reducing maintenance needs. The seasoning process for blue steel involves applying a thin layer of oil and heating it, which enhances durability but demands consistent care.

Standard baking sheets typically need simple cleaning with soap and water, as their non-stick or aluminum surfaces resist corrosion and staining. Blue steel sheets, if not dried thoroughly after washing, are prone to rust and must be stored in dry conditions to ensure longevity. Proper care of blue steel sheets extends their lifespan and improves curing performance compared to standard options.

Cost Analysis: Initial Investment and Lifespan

Standard baking sheets typically have a lower initial cost but a shorter lifespan compared to Blue Steel baking sheets, which require a higher upfront investment. Over time, Blue Steel sheets offer better durability and performance, often justifying their greater expense through extended use.

- Lower Initial Cost - Standard baking sheets are more affordable initially, making them accessible for beginner curing projects.

- Durability - Blue Steel baking sheets resist warping and corrosion better, contributing to a longer service life.

- Long-term Value - Despite higher cost, Blue Steel's longevity reduces replacement frequency, lowering overall cost of ownership.

The choice between these sheets depends on balancing upfront budget constraints and desired lifespan efficiency.

Choosing the Right Baking Sheet for Curing

| Standard Baking Sheet | Aluminum or stainless steel composition offers even heat distribution with moderate thermal conductivity, ideal for general curing processes. Non-reactive surface minimizes contamination but may require parchment paper to prevent sticking during prolonged curing. Typically less expensive and widely available, suitable for basic home curing needs. |

| Blue Steel Baking Sheet | Constructed from carbon steel with a distinctive blue oxide coating, which enhances rust resistance and durability, making it ideal for high-moisture curing environments. Superior heat retention and distribution improve consistent curing results by maintaining stable temperatures. Requires seasoning to maintain the protective layer but provides excellent longevity and performance for advanced curing applications. |

Related Important Terms

Heat Retention Differential

Blue steel baking sheets offer superior heat retention compared to standard aluminum baking sheets, ensuring more consistent and even curing by maintaining stable temperatures throughout the process. This enhanced thermal conductivity reduces hot spots and improves moisture evaporation, resulting in better-quality cured products.

Thermal Conductivity Index

Blue steel baking sheets demonstrate a higher Thermal Conductivity Index compared to standard baking sheets, enabling more efficient and even heat transfer crucial for optimal curing. This superior thermal conduction minimizes hot spots and ensures consistent curing outcomes, enhancing product quality and process reliability.

Blue Steel Seasoning Effect

Blue steel baking sheets offer superior curing results due to their enhanced seasoning effect, which creates a naturally non-stick surface that improves heat distribution and food release. This seasoned layer not only boosts durability but also enhances flavor development compared to standard aluminum baking sheets.

Nonstick Patina Formation

Blue steel baking sheets develop a nonstick patina through repeated curing cycles, enhancing release and reducing the need for oils, while standard baking sheets often lack this natural seasoning and may require added coatings. This patina formation on blue steel improves heat retention and distribution, critical for consistent curing performance.

Micro-pore Surface Texture

Blue steel baking sheets feature a micro-pore surface texture that enhances airflow and moisture evaporation during curing, leading to more even drying and improved product quality compared to standard baking sheets. Standard baking sheets, with their smoother surfaces, tend to retain more moisture, which can hinder the curing process and result in less consistent outcomes.

Reactive Steel Oxidation

Standard baking sheets, typically made of aluminum or coated steel, offer moderate resistance to reactive steel oxidation during curing but may degrade over time when exposed to acidic or high-moisture environments. Blue steel baking sheets, composed of carbon steel with a protective blue oxide layer, provide superior durability and oxidation resistance, maintaining structural integrity and enhancing curing quality by preventing reactive discoloration and corrosion.

Sheet Warping Resistance

Blue steel baking sheets offer superior warping resistance compared to standard baking sheets due to their thicker gauge and enhanced heat retention properties, maintaining flatness under high-temperature curing processes. This durability ensures even heat distribution and consistent curing results without the need for frequent replacement or adjustment.

Carbon Steel Cure Layering

Carbon steel baking sheets, particularly blue steel variants, develop a durable, non-stick carbon steel cure layering through seasoning that enhances heat retention and corrosion resistance compared to standard aluminum baking sheets. This carbon steel cure layer improves the curing process by ensuring more even heat distribution and a naturally protective surface that intensifies flavor development during cooking.

Blue Steel Polymerization Rate

Blue steel baking sheets demonstrate a significantly higher polymerization rate during curing compared to standard baking sheets, leading to enhanced durability and improved surface hardness. This accelerated polymerization contributes to better heat retention and more uniform curing outcomes, making blue steel sheets ideal for processes requiring precise temperature control.

Standard Baking Sheet vs Blue Steel Baking Sheet for curing. Infographic

cookingdiff.com

cookingdiff.com