Traditional oil curing relies on the slow oxidation of oils to form a protective film on pans, providing durability but often resulting in longer curing times and uneven coating. Flaxseed polymerization, by contrast, involves the rapid cross-linking of flaxseed oil molecules when heated, creating a harder, more uniform, and non-stick surface more efficiently. This method enhances pan longevity and resistance to wear while reducing the curing process duration.

Table of Comparison

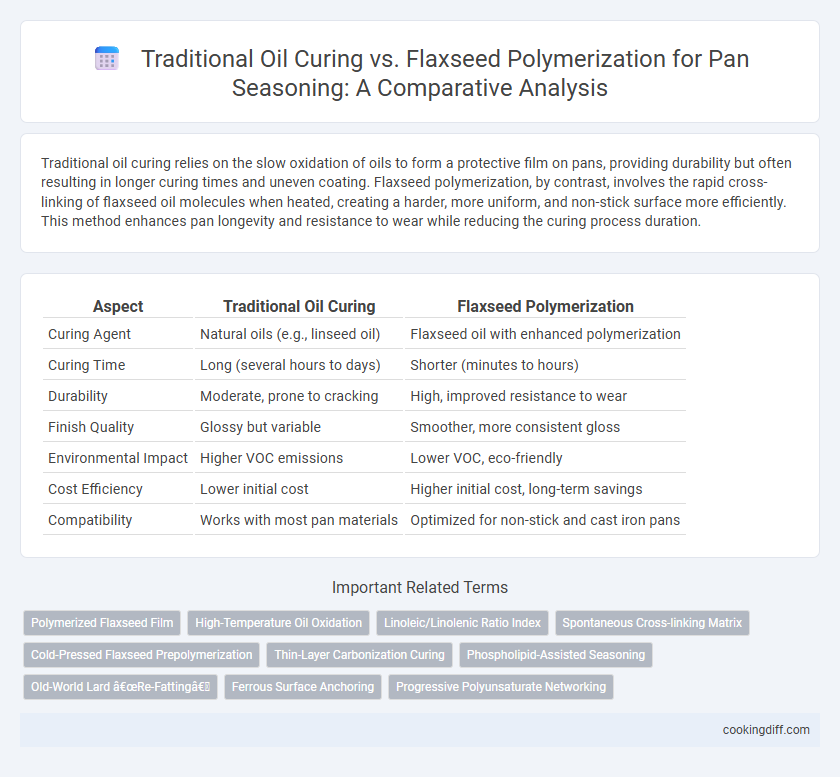

| Aspect | Traditional Oil Curing | Flaxseed Polymerization |

|---|---|---|

| Curing Agent | Natural oils (e.g., linseed oil) | Flaxseed oil with enhanced polymerization |

| Curing Time | Long (several hours to days) | Shorter (minutes to hours) |

| Durability | Moderate, prone to cracking | High, improved resistance to wear |

| Finish Quality | Glossy but variable | Smoother, more consistent gloss |

| Environmental Impact | Higher VOC emissions | Lower VOC, eco-friendly |

| Cost Efficiency | Lower initial cost | Higher initial cost, long-term savings |

| Compatibility | Works with most pan materials | Optimized for non-stick and cast iron pans |

Understanding Pan Curing: The Basics

Traditional oil curing involves applying linseed or other drying oils that polymerize to form a hard, protective layer on the pan surface. Flaxseed polymerization utilizes flaxseed oil for a more natural and durable seasoning that enhances non-stick properties over time.

- Traditional Oil Curing - Uses drying oils that oxidize and harden upon heating to create a protective coating.

- Flaxseed Polymerization - Flaxseed oil undergoes polymerization, resulting in a robust and smooth seasoning layer.

- Pan Curing Fundamentals - Both methods depend on heat-induced chemical reactions to bond oil molecules with the pan surface for durability.

Traditional Oil Curing Methods Explained

| Traditional oil curing involves applying natural oils such as linseed or tung oil to the pan surface, allowing slow oxidation to form a protective polymerized layer. This method relies on heat to gradually polymerize the oils, creating a non-stick, rust-resistant coating through multiple seasoning cycles. Compared to flaxseed polymerization, traditional oil curing offers a more straightforward process but may require longer curing times and frequent maintenance for optimal durability. |

What Is Flaxseed Polymerization?

Flaxseed polymerization involves the chemical transformation of flaxseed oil molecules into a hardened, protective layer through oxidation and cross-linking reactions. This process is utilized in pan curing to create a durable, non-stick surface that resists wear and corrosion better than traditional oil curing methods. Unlike conventional oil curing, flaxseed polymerization forms a more stable and long-lasting coating due to the high content of polyunsaturated fatty acids in flaxseed oil.

Science Behind Polymerization in Pan Curing

How does the science behind polymerization differ between traditional oil curing and flaxseed oil in pan curing? Traditional oil curing relies on oxidative cross-linking of unsaturated fatty acids to form a hardened film, which can be slower and less uniform. Flaxseed oil polymerization involves rapid drying through a high content of alpha-linolenic acid, promoting faster and more thorough curing for improved pan surface durability.

Pros and Cons: Traditional Oils vs Flaxseed Oil

Traditional oil curing relies on natural oils like linseed, creating a durable, moisture-resistant layer through slow polymerization, but can take longer to fully cure and may emit stronger odors. Flaxseed oil polymerization offers a faster drying time with a smoother finish, though it can be less durable and may require more frequent reapplications.

- Traditional oil curing durability - Provides a robust, long-lasting protective layer ideal for heavy use.

- Flaxseed oil faster drying - Accelerates curing time, reducing wait periods between coats.

- Traditional oils stronger odor - Emits more noticeable smells during application and curing.

Step-by-Step Guide: Traditional Oil Curing

Traditional oil curing for pan curing involves heating the pan to a specific temperature before applying a thin layer of oil, typically flaxseed or vegetable oil. This process promotes polymerization, forming a durable, non-stick coating on the pan's surface.

After oil application, the pan is heated in an oven for about one hour at 450degF (232degC) to ensure the oil fully polymerizes, creating a hard, protective layer. Repeating this step multiple times enhances the seasoning's durability and non-stick properties, essential for effective pan curing.

Step-by-Step Guide: Flaxseed Oil Polymerization

Flaxseed oil polymerization involves heating the oil to initiate a chemical reaction that forms a durable, cross-linked film ideal for pan curing. This process requires maintaining temperatures between 220degF and 265degF for several hours to achieve optimal polymerization and surface hardness. Unlike traditional oil curing, flaxseed oil polymerization provides enhanced durability and resistance to food acids and moisture.

Durability and Longevity: Which Method Lasts Longer?

Traditional oil curing forms a durable, hard finish by polymerizing oils through exposure to air, typically resulting in a surface that can last several years with proper maintenance. However, this method is prone to cracking and wear over time due to environmental factors like moisture and temperature fluctuations.

Flaxseed polymerization for pan curing creates a more flexible and resilient coating that penetrates deeper into the material, enhancing longevity and resistance to degradation. Its molecular structure provides superior durability, especially in high-heat or high-moisture conditions, often extending the lifespan beyond that of traditional oil curing.

Flavor and Cooking Results Comparison

Traditional oil curing imparts a rich, smoky flavor to pans, enhancing the cooking experience with natural seasoning that develops over time. Flaxseed polymerization creates a hard, durable coating with a slightly nutty aroma, offering a non-stick surface that improves food release during cooking.

The flavor profile of pans cured with traditional oils tends to deepen as oils oxidize and bond with the metal, producing complex tastes especially suited for searing and frying. Flaxseed polymerization forms a smooth, resilient layer that resists flaking and improves heat distribution, ideal for high-temperature cooking. While traditional oil curing may require more frequent maintenance, flaxseed polymerization provides a longer-lasting seasoning that enhances both performance and flavor retention in everyday cooking.

Related Important Terms

Polymerized Flaxseed Film

Polymerized flaxseed film offers superior oxygen barrier and natural antioxidant properties compared to traditional oil curing methods, enhancing the shelf life and flavor stability of cured products. Its bio-based, non-toxic composition forms a durable, flexible coating that improves pan curing efficiency by reducing moisture loss and preventing oxidative rancidity.

High-Temperature Oil Oxidation

Traditional oil curing relies on high-temperature oil oxidation to form a durable polymer film on the pan surface, where unsaturated fatty acids in drying oils such as linseed undergo oxidative cross-linking. Flaxseed polymerization leverages the high concentration of polyunsaturated fatty acids, enhancing oxidative polymerization kinetics and resulting in a more uniform and resilient cured layer resistant to thermal degradation.

Linoleic/Linolenic Ratio Index

The Linoleic/Linolenic Ratio Index is a critical factor differentiating traditional oil curing from flaxseed polymerization in pan curing, where flaxseed polymerization offers a more balanced ratio enhancing film formation and durability. Traditional oils often have a higher linoleic acid content, which can lead to faster drying but less flexible films compared to the flaxseed-derived polymers that optimize the linoleic/linolenic balance for superior curing performance.

Spontaneous Cross-linking Matrix

Traditional oil curing relies on the slow oxidation of drying oils such as linseed oil, forming a spontaneous cross-linking matrix through autoxidation and polymerization of unsaturated fatty acids. Flaxseed polymerization enhances pan curing by promoting rapid cross-linking and forming a dense, durable polymer network that improves the curing efficiency and surface hardness.

Cold-Pressed Flaxseed Prepolymerization

Cold-pressed flaxseed prepolymerization enhances pan curing by forming a durable, oxidation-resistant film compared to traditional oil curing methods, which often result in uneven surface texture and longer drying times. This advanced polymerization process optimizes curing efficiency through improved film adhesion and faster solvent evaporation, leading to superior pan surface durability and non-stick properties.

Thin-Layer Carbonization Curing

Thin-layer carbonization curing in traditional oil curing relies on the slow oxidation and polymerization of linseed oils, forming a durable, flexible film through surface drying and cross-linking. Flaxseed polymerization enhances this process by promoting rapid, controlled curing with improved uniformity and adhesion, resulting in superior thin-film carbonization for pan curing applications.

Phospholipid-Assisted Seasoning

Phospholipid-assisted seasoning enhances the pan curing process by facilitating polymerization of flaxseed oil, resulting in a more durable and hydrophobic coating compared to traditional oil curing methods. The higher concentration of phospholipids in flaxseed oil promotes cross-linking of fatty acids, improving adhesion and corrosion resistance on cookware surfaces.

Old-World Lard “Re-Fatting”

Traditional oil curing relies on animal fats like Old-World lard for re-fatting, enhancing pan seasoning by forming a durable, flavorful layer through polymerization at high heat. Flaxseed oil polymerization offers a plant-based alternative, creating a robust, non-stick surface through oxidative drying and cross-linking of polyunsaturated fatty acids during pan curing.

Ferrous Surface Anchoring

Traditional oil curing relies on polymerization of drying oils that form cross-linked films anchored to ferrous surfaces through polar interactions and oxidative cross-linking, providing robust corrosion resistance. Flaxseed polymerization enhances ferrous surface anchoring by generating denser, more uniform polymer networks rich in polyunsaturated fatty acids, resulting in superior adhesion and long-lasting protective coatings.

Traditional oil curing vs flaxseed polymerization for pan curing. Infographic

cookingdiff.com

cookingdiff.com