Pressing stones provide consistent, even pressure for curing, ensuring moisture is expelled uniformly and preventing uneven fermentation. Fermentation weights, typically made of ceramic or glass, allow some air circulation, promoting beneficial microbial activity that enhances flavor complexity. Choosing between pressing stones and fermentation weights depends on the desired texture and taste, with stones offering firm results and weights encouraging nuanced fermentation.

Table of Comparison

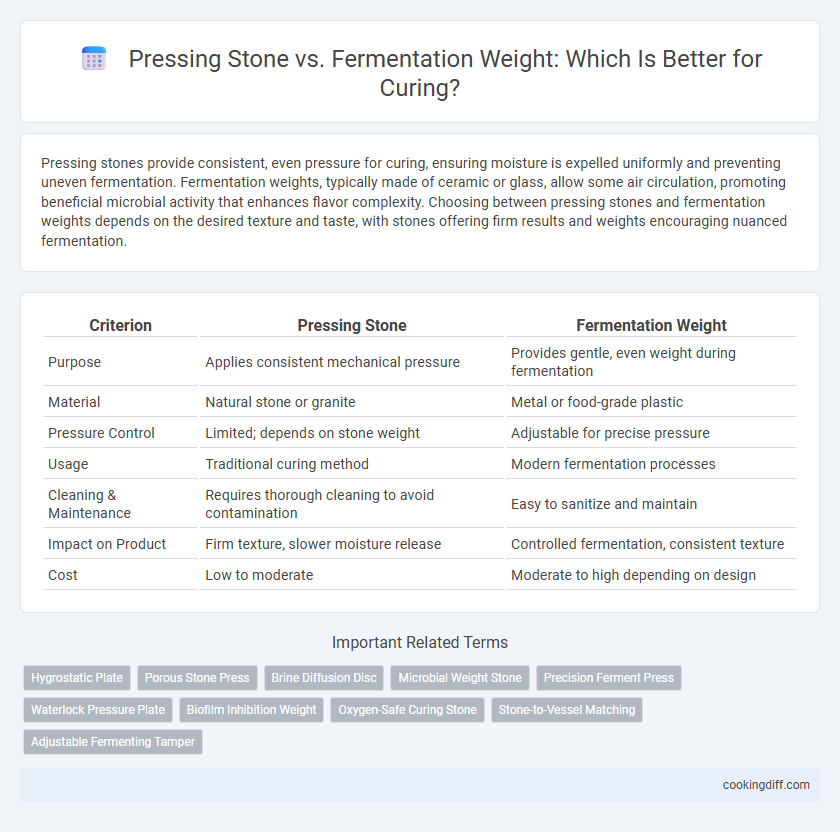

| Criterion | Pressing Stone | Fermentation Weight |

|---|---|---|

| Purpose | Applies consistent mechanical pressure | Provides gentle, even weight during fermentation |

| Material | Natural stone or granite | Metal or food-grade plastic |

| Pressure Control | Limited; depends on stone weight | Adjustable for precise pressure |

| Usage | Traditional curing method | Modern fermentation processes |

| Cleaning & Maintenance | Requires thorough cleaning to avoid contamination | Easy to sanitize and maintain |

| Impact on Product | Firm texture, slower moisture release | Controlled fermentation, consistent texture |

| Cost | Low to moderate | Moderate to high depending on design |

Overview of Curing: Pressing Stone vs Fermentation Weight

Pressing stones and fermentation weights serve as essential tools in the curing process, each influencing moisture extraction and texture development differently. Pressing stones provide consistent pressure ideal for firm curing, whereas fermentation weights offer adjustable pressure suitable for dynamic fermentation stages.

- Pressing Stone - Delivers uniform, static pressure to ensure even moisture removal and product firmness.

- Fermentation Weight - Applies variable pressure, accommodating gas release and product expansion during fermentation.

- Impact on Curing - Choice affects texture, flavor development, and microbial activity by altering pressure and airflow.

Understanding the functional differences between pressing stones and fermentation weights is vital for optimizing curing outcomes based on the specific curing technique and product requirements.

Historical Uses: Pressing Stones in Traditional Curing

Pressing stones have been historically utilized in traditional curing methods to apply consistent pressure on foods like kimchi and sauerkraut, facilitating moisture release and fermentation. Their weight ensured an anaerobic environment, essential for proper preservation and flavor development.

Before the widespread use of fermentation weights, large pressing stones offered a natural and durable solution that maintained pressure evenly over several weeks. This technique remains vital in some artisanal food production for achieving authentic taste and texture.

Modern Fermentation Weights: Evolution in Curing Practices

Modern fermentation weights have transformed curing practices by offering more consistent pressure compared to traditional pressing stones, enhancing flavor development. These innovative weights enable precise control of fermentation, reducing spoilage and promoting uniform texture in cured products.

- Consistent Pressure Application - Modern weights apply even pressure throughout fermentation, improving the quality of the cured product.

- Enhanced Flavor Development - Controlled weight improves microbial activity, resulting in richer and more complex flavors.

- Reduced Spoilage Risk - Precise pressure control lowers contamination chances, ensuring safer curing processes.

Material Comparison: Stone vs Glass, Ceramic, and Metal Weights

Stone weights provide natural porosity allowing slight air exchange, which benefits fermentation-based curing by reducing moisture buildup more effectively than glass, ceramic, or metal weights. Glass and ceramic weights are non-reactive and easy to clean but lack the breathability and slight absorbency of stone, potentially leading to excess moisture retention.

Metal weights offer durability and consistent pressure but may react with acidic fermenting foods, affecting flavor and safety over time. Stone weights' natural mineral composition can contribute trace elements that subtly enhance curing processes, unlike inert glass or ceramic. The choice depends on balancing material reactivity, weight distribution, and breathability to achieve optimal fermentation and curing results.

Pressure Distribution and Effectiveness

Pressing stone provides a consistent and evenly distributed pressure over the curing surface, enhancing moisture retention and texture uniformity. Fermentation weight, although adjustable, may result in uneven pressure distribution due to its irregular shape, potentially causing inconsistent curing. Consistent pressure from pressing stone improves curing effectiveness by facilitating better enzyme activity and preventing spoilage during the fermentation process.

Hygiene and Maintenance: Cleaning Considerations

Which method offers better hygiene and easier maintenance during curing: pressing stone or fermentation weight? Pressing stones typically have a solid, non-porous surface that resists bacterial growth and is simpler to clean thoroughly. Fermentation weights, often made from plastic or ceramic materials, may have crevices that require more detailed cleaning to prevent mold and contamination during prolonged use.

Impact on Flavor and Texture Development

| Pressing Stone | Applying a pressing stone exerts consistent pressure, which can lead to denser texture and subtle flavor intensification by limiting oxygen exposure during curing. |

| Fermentation Weight | Using fermentation weight allows controlled pressure with gradual release, enhancing complex flavor profiles and promoting balanced moisture retention that improves tenderness and aroma development. |

Suitability for Various Foods: Vegetables, Meats, and More

Pressing stones provide consistent pressure ideal for curing dense vegetables like cabbage and root crops, ensuring firm texture and enhanced flavor retention. Fermentation weights offer gentle, even pressure suited for delicate items such as sauerkraut and fermented meats, promoting microbial activity without crushing the food. Both methods cater to diverse curing needs, with pressing stones excelling in firm vegetable preservation and fermentation weights optimizing flavor development in more sensitive foods.

Practicality and Accessibility for Home Curers

Pressing stone offers a straightforward, low-maintenance solution for curing, requiring minimal equipment and making it highly accessible for home curers. Its consistent, even pressure helps remove excess moisture without the need for specialized knowledge or monitoring.

Fermentation weight provides more precise control over humidity and pressure but demands careful handling and attention to avoid spoilage, which can be challenging for beginners. For practical, everyday home curing, pressing stones balance efficiency and ease, ensuring reliable results with less effort.

Related Important Terms

Hygrostatic Plate

The Hygrostatic Plate applies consistent, controlled pressure during curing, enhancing moisture retention and texture development in fermentation weights compared to traditional stone pressing. Its precise pressure regulation minimizes product deformation and promotes uniform microbial activity, optimizing overall curing quality.

Porous Stone Press

Porous stone press provides consistent, gentle pressure ideal for curing processes where moisture control and air circulation are critical, enhancing fermentation by allowing gases to escape while maintaining compactness. Compared to fermentation weights, porous stone presses reduce the risk of spoilage and uneven curing by promoting better drainage and airflow, resulting in improved texture and flavor development.

Brine Diffusion Disc

Brine Diffusion Disc leverages controlled pressure applied to pressing stone, enhancing uniform salt penetration compared to traditional fermentation weight methods. This optimized curing technique accelerates osmosis, ensuring consistent moisture retention and flavor development in cured products.

Microbial Weight Stone

Pressing stone curing relies on Microbial Weight Stone to apply consistent pressure that inhibits undesirable microbial growth while promoting beneficial fermentation, ensuring optimal texture and flavor development. Fermentation weight, however, lacks the precision of Microbial Weight Stone, potentially leading to uneven curing conditions and suboptimal microbial activity control.

Precision Ferment Press

Precision Ferment Press uses controlled fermentation weight to enhance curing by evenly distributing pressure, minimizing moisture loss and promoting consistent flavor development compared to traditional pressing stone methods. This technique optimizes microbial activity for superior texture and taste in cured products.

Waterlock Pressure Plate

Waterlock Pressure Plate offers precise control over curing pressure by evenly distributing weight, which surpasses traditional pressing stones that often create uneven pressure and risk damaging delicate products. This technology enhances fermentation consistency and improves moisture retention, leading to optimal texture and flavor during the curing process.

Biofilm Inhibition Weight

Pressing stone applies a consistent, uniform pressure that effectively inhibits biofilm formation by reducing surface moisture and limiting microbial growth during curing. Fermentation weight, while providing variable pressure influenced by gas production, may allow residual moisture pockets that facilitate biofilm development, making pressing stone a more reliable method for biofilm inhibition weight in curing processes.

Oxygen-Safe Curing Stone

Oxygen-Safe Curing Stone offers a controlled environment by utilizing pressing stone that limits oxygen exposure, enhancing flavor preservation and preventing spoilage during the curing process. Fermentation weight methods may introduce variable oxygen levels, whereas pressing stone ensures consistent pressure and optimal anaerobic conditions critical for high-quality curing.

Stone-to-Vessel Matching

Pressing stone to vessel matching is vital for optimal curing efficiency, as the stone's weight directly influences pressure distribution and moisture retention; heavier stones typically provide consistent compression, while fermentation weights offer more controlled, gradual pressure adjustments. Properly matched stone and vessel sizes prevent ingredient damage and ensure uniform curing, enhancing flavor development and texture preservation in fermented foods.

Pressing stone vs fermentation weight for curing. Infographic

cookingdiff.com

cookingdiff.com