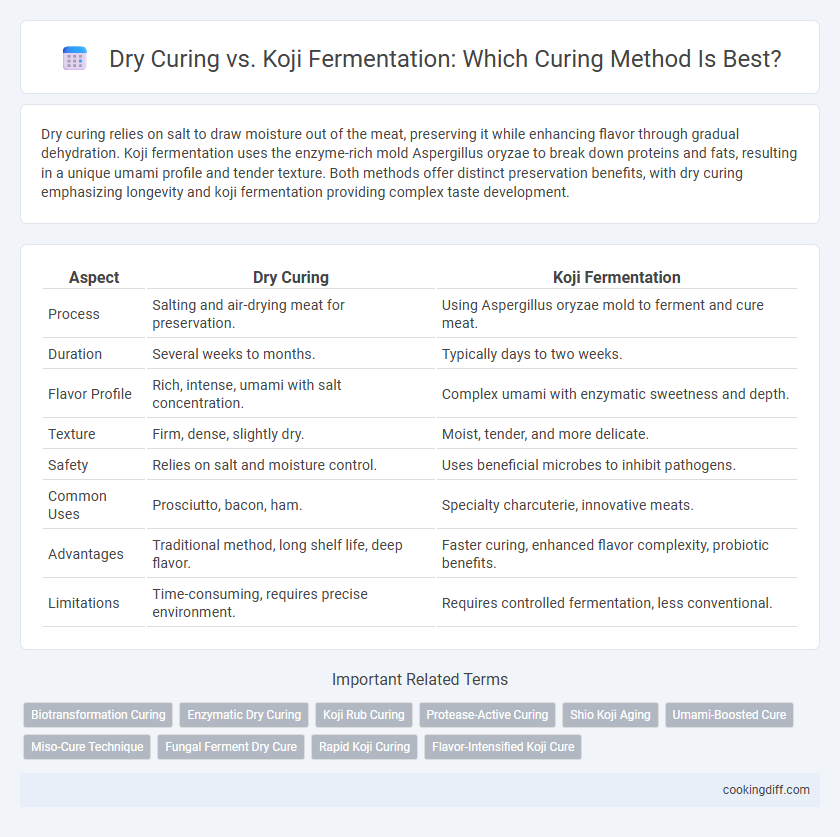

Dry curing relies on salt to draw moisture out of the meat, preserving it while enhancing flavor through gradual dehydration. Koji fermentation uses the enzyme-rich mold Aspergillus oryzae to break down proteins and fats, resulting in a unique umami profile and tender texture. Both methods offer distinct preservation benefits, with dry curing emphasizing longevity and koji fermentation providing complex taste development.

Table of Comparison

| Aspect | Dry Curing | Koji Fermentation |

|---|---|---|

| Process | Salting and air-drying meat for preservation. | Using Aspergillus oryzae mold to ferment and cure meat. |

| Duration | Several weeks to months. | Typically days to two weeks. |

| Flavor Profile | Rich, intense, umami with salt concentration. | Complex umami with enzymatic sweetness and depth. |

| Texture | Firm, dense, slightly dry. | Moist, tender, and more delicate. |

| Safety | Relies on salt and moisture control. | Uses beneficial microbes to inhibit pathogens. |

| Common Uses | Prosciutto, bacon, ham. | Specialty charcuterie, innovative meats. |

| Advantages | Traditional method, long shelf life, deep flavor. | Faster curing, enhanced flavor complexity, probiotic benefits. |

| Limitations | Time-consuming, requires precise environment. | Requires controlled fermentation, less conventional. |

Introduction to Dry Curing and Koji Fermentation

Dry curing is a traditional preservation method involving the application of salt to draw moisture out of food, enhancing flavor and texture. Koji fermentation utilizes Aspergillus oryzae mold to enzymatically break down proteins and starches, creating complex umami flavors during curing.

- Dry curing process - salt absorption dehydrates food, inhibiting microbial growth and concentrating taste.

- Koji fermentation mechanism - enzymatic action by koji mold converts macromolecules into flavorful compounds.

- Flavor development - dry curing intensifies natural meat flavors while koji fermentation introduces unique savory notes through fermentation.

Historical Background of Both Methods

Dry curing is an ancient preservation method dating back thousands of years, primarily used in Mediterranean and European cultures to enhance the flavor and shelf life of meats through salt and air drying. This technique relies on controlled environmental conditions to draw moisture out, preventing bacterial growth without the need for additional fermentation agents.

Koji fermentation, originating from East Asia over 2,000 years ago, employs the mold Aspergillus oryzae to break down proteins and carbohydrates, traditionally used in Japanese and Korean food production for soy sauce, miso, and fermented fish. Its application to curing meats is a more recent innovation that integrates fermentation science with traditional preservation methods to develop unique flavors and textures.

How Dry Curing Works: Process and Principles

How does dry curing preserve and enhance the flavor of foods? Dry curing works by applying salt directly to the product, drawing out moisture to inhibit bacterial growth and concentrate flavors. The process relies on osmosis and enzymatic reactions to develop complex tastes and firm textures over time.

Koji Fermentation Explained: Mechanisms and Microbes

Koji fermentation utilizes the mold Aspergillus oryzae to break down proteins and starches in curing processes, enhancing flavor and texture through enzymatic activity. The enzymes produced, such as proteases and amylases, accelerate the breakdown of complex molecules into amino acids and sugars, resulting in a rich umami profile. Unlike traditional dry curing, koji fermentation offers a controlled microbial environment that reduces curing time while introducing unique flavors and improved tenderness.

Flavor Profiles: Comparing Taste Outcomes

| Dry Curing | Koji Fermentation |

|---|---|

| Develops intense, savory umami notes with a firm texture through slow moisture loss and salt penetration. | Produces complex, sweet-savory flavors by enzymatic breakdown of proteins and starches, enhancing depth and subtlety. |

| Emphasizes salt-forward and nutty undertones, often resulting in a pronounced cured aroma. | Creates mild acidity and rich aromatics due to fermentation-derived amino acids and peptides. |

| Flavor matures over weeks to months, intensifying with time and environmental factors like humidity and air flow. | Flavor evolves faster, driven by microbial activity and controlled temperature, yielding distinct but delicate taste profiles. |

Texture Differences in Cured Foods

Dry curing produces a firmer, denser texture in cured foods due to moisture loss and protein concentration, resulting in a chewy and compact bite. Koji fermentation breaks down proteins and fats enzymatically, creating a tender, melt-in-mouth texture with enhanced umami and subtle sweetness. The contrast in textures highlights dry curing's preservation method versus koji's enzymatic transformation in cured meats and fish.

Health and Safety Considerations

Dry curing relies on salt to inhibit bacterial growth, which effectively preserves meats with minimal risk of harmful pathogens. Koji fermentation, using Aspergillus oryzae, enhances flavor and digestion but requires strict control to prevent contamination and ensure safety.

- Microbial control - Dry curing uses salt concentration to limit microbial growth, while koji fermentation depends on controlled mold activity for safety.

- Allergen risk - Koji fermentation may pose allergen risks due to mold spores, requiring allergy warnings and proper handling.

- Temperature monitoring - Both methods require precise temperature regulation to prevent spoilage and ensure product safety.

Choosing between dry curing and koji fermentation depends on balancing traditional preservation with fermentation benefits while maintaining strict health protocols.

Traditional Applications vs. Modern Innovations

Dry curing is a centuries-old method that relies on salt and time to preserve meat, emphasizing traditional flavor development and texture enhancement. Koji fermentation introduces enzymatic action from Aspergillus oryzae, offering modern innovations in curing with accelerated maturation and unique umami profiles.

- Dry curing's traditional application - Utilizes salt and extended aging to inhibit microbial growth and develop complex flavors in meats like prosciutto and jamon.

- Koji fermentation as a modern innovation - Employs mold enzymes to break down proteins and fats rapidly, enhancing taste and reducing curing time.

- Contrast in preservation techniques - Dry curing depends on moisture reduction and salt penetration, while koji fermentation leverages microbial enzymatic activity for preservation and flavor creation.

Environmental Impact and Sustainability

Dry curing requires significant energy and water resources for maintaining controlled environments, impacting sustainability due to its extended processing times. Koji fermentation uses natural enzymes, reducing energy consumption and waste output, making it an eco-friendlier alternative.

Environmental impact assessments show koji fermentation lowers greenhouse gas emissions by minimizing refrigeration and drying needs. The microbial process enhances nutrient recycling, supporting soil health when waste products are composted. Sustainable practices in koji fermentation contribute to reduced resource depletion compared to traditional dry curing methods.

Related Important Terms

Biotransformation Curing

Dry curing relies on salt-induced dehydration to preserve and enhance flavor through proteolysis and lipolysis, while koji fermentation utilizes Aspergillus oryzae enzymes to accelerate biotransformation by breaking down proteins and starches into amino acids and sugars, resulting in unique umami-rich flavors. Koji fermentation offers a controlled enzymatic process that intensifies curing efficiency and produces distinct aromatic compounds compared to the slower, traditional dry curing method.

Enzymatic Dry Curing

Enzymatic dry curing relies on naturally occurring proteases and lipases to break down proteins and fats, enhancing flavor and texture without adding moisture or altering the product's structural integrity. Koji fermentation introduces mold-derived enzymes that accelerate proteolysis and lipolysis, but enzymatic dry curing maintains a traditional, slow maturation process critical for developing complex taste profiles in products like dry-cured ham and artisanal sausages.

Koji Rub Curing

Koji rub curing utilizes Aspergillus oryzae enzymes to accelerate protein breakdown and enhance umami flavor, resulting in tender, savory cured meats with reduced salt content compared to traditional dry curing methods. This fermentation-based technique offers a faster curing process, improved moisture retention, and unique flavor complexity driven by enzymatic reactions.

Protease-Active Curing

Protease-active curing techniques leverage enzymes to break down proteins, enhancing texture and flavor development in dry curing and koji fermentation processes. Koji fermentation utilizes Aspergillus oryzae-produced proteases for accelerated and controlled proteolysis, while traditional dry curing relies on endogenous muscle enzymes activated over longer maturation periods.

Shio Koji Aging

Shio koji aging leverages the enzymatic activity of Aspergillus oryzae to break down proteins and enhance umami flavor, resulting in a tender texture and rich taste profile distinct from traditional dry curing methods that rely on salt for preservation. Unlike dry curing, which primarily removes moisture to inhibit bacterial growth, shio koji fermentation actively transforms the meat through natural fermentation, improving both flavor complexity and nutritional value.

Umami-Boosted Cure

Dry curing enhances flavor through moisture removal and salt penetration, intensifying natural meat umami by concentrating amino acids. Koji fermentation boosts umami by enzymatically breaking down proteins and starches into glutamates and peptides, creating a rich, savory profile beyond traditional salt curing techniques.

Miso-Cure Technique

Dry curing relies on salt extraction to preserve and flavor meats, creating a firm texture with concentrated taste, while koji fermentation employs Aspergillus oryzae enzymes to break down proteins and fats, enhancing umami and tenderizing the meat. The Miso-Cure Technique combines koji fermentation with traditional miso paste, accelerating curing by infusing rich amino acids and beneficial microbes that develop complex flavors and improve product safety.

Fungal Ferment Dry Cure

Fungal ferment dry cure utilizes specific fungi, such as Aspergillus oryzae (koji), to enhance enzymatic breakdown of proteins and fats, resulting in intensified umami flavors and improved texture compared to traditional dry curing methods. This process accelerates curing times while promoting complex flavor profiles through controlled microbial activity and moisture reduction.

Rapid Koji Curing

Rapid Koji Curing accelerates the traditional curing process by utilizing Aspergillus oryzae enzymes to break down proteins and fats more efficiently than dry curing, resulting in enhanced umami flavor and improved texture within a shorter timeframe. This method offers a hygienic alternative that reduces moisture loss and microbial risks while maintaining the preservation qualities and taste complexity characteristic of aged cured products.

Dry curing vs koji fermentation for curing. Infographic

cookingdiff.com

cookingdiff.com