Layered seasoning creates a natural, durable non-stick surface on utensils by applying multiple oil coatings that polymerize under heat, enhancing flavor release and preventing rust. Nano-coating technology provides a smooth, uniform, and highly resistant surface at the molecular level, offering superior durability and ease of cleaning without affecting taste. Choosing between layered seasoning and nano-coating depends on the desired balance of traditional flavor enhancement versus modern, low-maintenance surface protection for cooking tools.

Table of Comparison

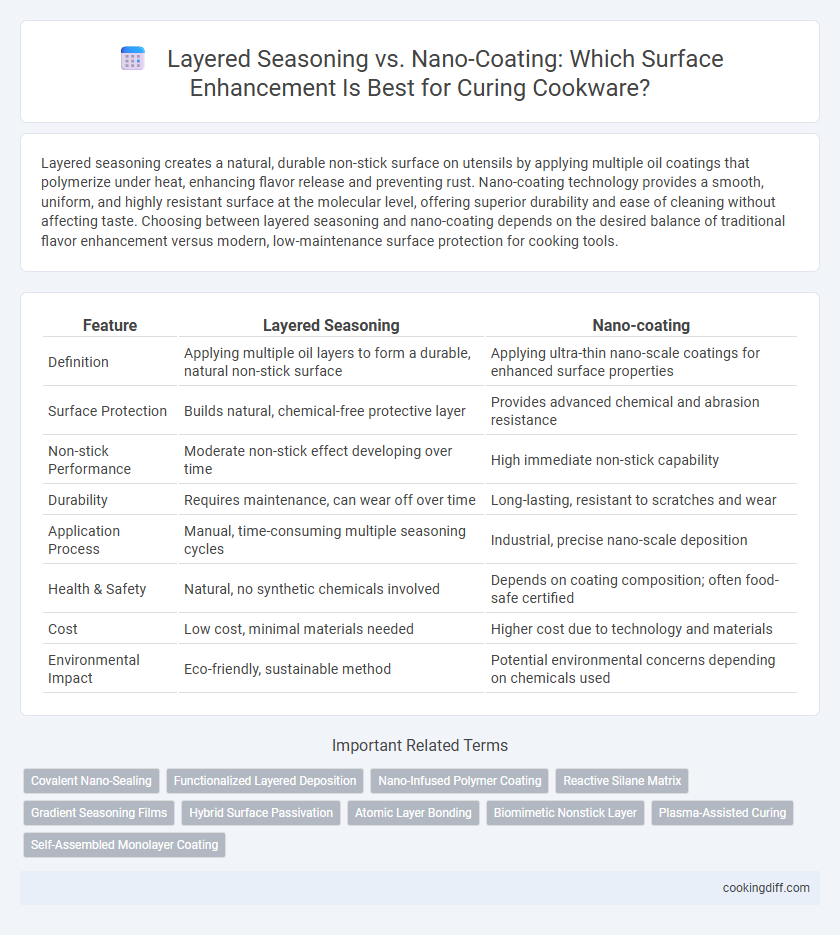

| Feature | Layered Seasoning | Nano-coating |

|---|---|---|

| Definition | Applying multiple oil layers to form a durable, natural non-stick surface | Applying ultra-thin nano-scale coatings for enhanced surface properties |

| Surface Protection | Builds natural, chemical-free protective layer | Provides advanced chemical and abrasion resistance |

| Non-stick Performance | Moderate non-stick effect developing over time | High immediate non-stick capability |

| Durability | Requires maintenance, can wear off over time | Long-lasting, resistant to scratches and wear |

| Application Process | Manual, time-consuming multiple seasoning cycles | Industrial, precise nano-scale deposition |

| Health & Safety | Natural, no synthetic chemicals involved | Depends on coating composition; often food-safe certified |

| Cost | Low cost, minimal materials needed | Higher cost due to technology and materials |

| Environmental Impact | Eco-friendly, sustainable method | Potential environmental concerns depending on chemicals used |

Introduction to Utensil Surface Enhancement

How do layered seasoning and nano-coating compare in enhancing utensil surfaces? Layered seasoning builds a natural, non-stick patina through polymerized oils, improving durability and flavor resistance. Nano-coating applies advanced thin films at the molecular level, providing superior corrosion resistance and hygienic properties for long-lasting utensil performance.

What Is Layered Seasoning?

Layered seasoning is a traditional technique that involves applying multiple coats of oil to a utensil's surface and heating it to create a durable, non-stick layer. This process builds up polymerized oil layers that enhance the utensil's resistance to rust and improve cooking performance. Unlike nano-coating, layered seasoning relies on natural oils and heat to form a protective, chemically bonded surface.

Understanding Nano-coating Technologies

Nano-coating technologies utilize advanced materials to create ultra-thin, durable layers on utensil surfaces, enhancing resistance to corrosion and wear without affecting utensil weight or balance. Compared to traditional layered seasoning, nano-coatings offer superior uniformity and long-term protection through molecular bonding techniques.

- Hydrophobic Properties - Nano-coatings can impart water-repellent surfaces, reducing sticking and facilitating easier cleaning.

- Enhanced Durability - Molecularly bonded coatings provide increased abrasion resistance beyond conventional seasoning layers.

- Food Safety Compliance - Many nano-coating materials meet regulatory standards for direct food contact, ensuring user safety.

Understanding nano-coating technologies is essential for selecting the optimal surface enhancement to improve utensil longevity and performance in curing applications.

Core Differences: Layered Seasoning vs Nano-coating

Layered seasoning creates a natural, polymerized layer through repeated oil heating that enhances non-stick properties and durability on utensil surfaces. Nano-coating involves applying a microscopic, often synthetic, thin film that provides uniform protection and resistance to corrosion and scratching. The core difference lies in seasoning's traditional, organic buildup versus nano-coating's engineered, precise surface modification for enhanced performance.

Durability and Lifespan Comparison

Layered seasoning techniques create a durable, polymerized oil coating that enhances utensil surface resilience against rust and wear over time. Nano-coating, utilizing advanced nanomaterials, offers superior hardness and hydrophobic properties, increasing resistance to scratches and corrosion.

Layered seasoning typically requires regular maintenance to sustain its protective qualities but can last several years with proper care. Nano-coating provides a longer lifespan due to its chemical stability and uniform application at the molecular level, significantly reducing surface degradation. Both methods improve utensil durability, but nano-coating offers enhanced longevity and consistent performance in demanding kitchen environments.

Impact on Cooking Performance

Layered seasoning builds a natural, porous surface that enhances heat distribution and food release by creating multiple protective layers over cast iron cookware. This method improves cooking performance by allowing better absorption of fats and oils, resulting in more even searing and reduced sticking during high-heat cooking.

Nano-coating utilizes advanced ceramic or polymer compounds to form a thin, non-stick barrier with superior resistance to abrasion and chemical damage. Its impact on cooking performance includes faster heating response and easy cleanup, but it may lack the seasoning's ability to develop flavor-enhancing patina over time.

Health and Safety Considerations

Layered seasoning enhances utensil surfaces by forming natural, non-toxic barriers that improve durability and reduce harmful chemical exposure. Nano-coating offers advanced protection with antimicrobial properties but may raise concerns about long-term safety and potential nanomaterial leaching.

- Layered Seasoning Safety - Uses natural oils that polymerize into a stable, food-safe layer, minimizing chemical risks.

- Nano-coating Risks - Potential for nanoparticle release during use may pose unknown health hazards.

- Health Impact - Layered seasoning is generally recognized as safe, while nano-coatings require further toxicological evaluation.

Maintenance and Re-seasoning Requirements

Layered seasoning on utensils requires frequent maintenance and periodic re-seasoning to maintain its protective and non-stick properties. Nano-coating offers a more durable surface with minimal upkeep, reducing the need for routine re-seasoning.

- Layered seasoning demands regular re-seasoning - Oil layers build up gradually and must be replenished after extensive use to prevent rust and maintain performance.

- Nano-coating provides long-lasting protection - The chemical bonds in nano-coatings resist wear and corrosion, significantly lowering maintenance frequency.

- Maintenance impacts utensil lifespan - Proper upkeep of layered seasoning extends usability, whereas nano-coatings deliver consistent durability with less intervention.

Environmental Effects and Sustainability

Layered seasoning improves utensil surface durability through natural polymerization of oils, reducing the need for synthetic coatings and minimizing environmental pollution. This method promotes sustainability by extending utensil lifespan and enabling biodegradability without releasing harmful chemicals into ecosystems.

Nano-coating enhances surface resistance using engineered nanoparticles, but it often involves energy-intensive production and potential nanoparticle leaching, raising environmental concerns. Sustainable nano-coatings require careful selection of eco-friendly materials and thorough life-cycle assessments to mitigate ecological impact.

Related Important Terms

Covalent Nano-Sealing

Covalent nano-sealing forms a robust, molecularly bonded layer on utensil surfaces, providing superior resistance to corrosion and enhancing flavor retention compared to traditional layered seasoning methods. This advanced nano-coating technique ensures long-lasting durability and hygiene by preventing food adhesion and reducing microbial growth at the atomic scale.

Functionalized Layered Deposition

Functionalized Layered Deposition in curing creates durable, corrosion-resistant utensil surfaces by precisely applying multiple seasoning layers that enhance adhesion and longevity. Compared to nano-coating, layered seasoning offers superior structural integrity and controlled thickness, improving heat distribution and food release properties.

Nano-Infused Polymer Coating

Nano-infused polymer coatings create a durable, anti-corrosive barrier on utensil surfaces that significantly improves resistance to wear and microbial contamination compared to traditional layered seasoning methods. Their nanostructured composition enhances surface smoothness and food-release properties, extending utensil lifespan and reducing maintenance requirements.

Reactive Silane Matrix

Reactive Silane Matrix in nano-coating forms a durable, hydrophobic layer that enhances utensil surface resistance to stains and corrosion, outperforming traditional layered seasoning by creating a chemically bonded, non-porous barrier. This advanced coating method improves longevity and ease of cleaning, ensuring optimal curing and utensil performance through molecular-level surface enhancement.

Gradient Seasoning Films

Gradient seasoning films enhance utensil surfaces by creating a controlled, multilayered coating that improves non-stick properties and corrosion resistance, outperforming traditional nano-coating methods. Layered seasoning allows precise manipulation of thickness and composition, enabling gradual transitions in surface characteristics that optimize durability and culinary performance.

Hybrid Surface Passivation

Hybrid surface passivation combines layered seasoning and nano-coating techniques to enhance utensil surface durability and corrosion resistance. This method optimizes barrier properties by integrating micro-scale seasoning layers with nano-scale protective films, resulting in superior curing performance and extended utensil lifespan.

Atomic Layer Bonding

Layered seasoning creates a textured surface through repeated applications of fat that polymerize and bond at a micro-level, enhancing non-stick properties and corrosion resistance via atomic layer interactions. Nano-coating utilizes atomic layer deposition techniques to form ultra-thin, uniform films that chemically bond to the utensil surface, offering superior durability and enhanced resistance to wear, corrosion, and food adhesion at the atomic scale.

Biomimetic Nonstick Layer

Biomimetic nonstick layers in curing processes leverage nano-coating technology to replicate natural non-adhesive surfaces, providing superior durability and resistance compared to traditional layered seasoning methods. This advanced surface enhancement reduces food adhesion and simplifies cleaning while maintaining utensil integrity over prolonged use.

Plasma-Assisted Curing

Plasma-assisted curing enhances utensil surfaces by enabling the formation of durable nano-coatings that provide superior resistance to corrosion, wear, and contamination compared to traditional layered seasoning techniques. This advanced method induces strong chemical bonds at the molecular level, resulting in uniform, thin films that improve utensil longevity and hygiene with minimal environmental impact.

Layered Seasoning vs Nano-coating for utensil surface enhancement. Infographic

cookingdiff.com

cookingdiff.com