Curing a pizza steel enhances its rust resistance and creates a natural non-stick surface, improving overall cooking performance. Smoke infusion imparts a subtle smoky flavor but may not provide the same protective benefits as curing. Prioritizing curing ensures durability and consistent heat retention for perfectly cooked pizzas.

Table of Comparison

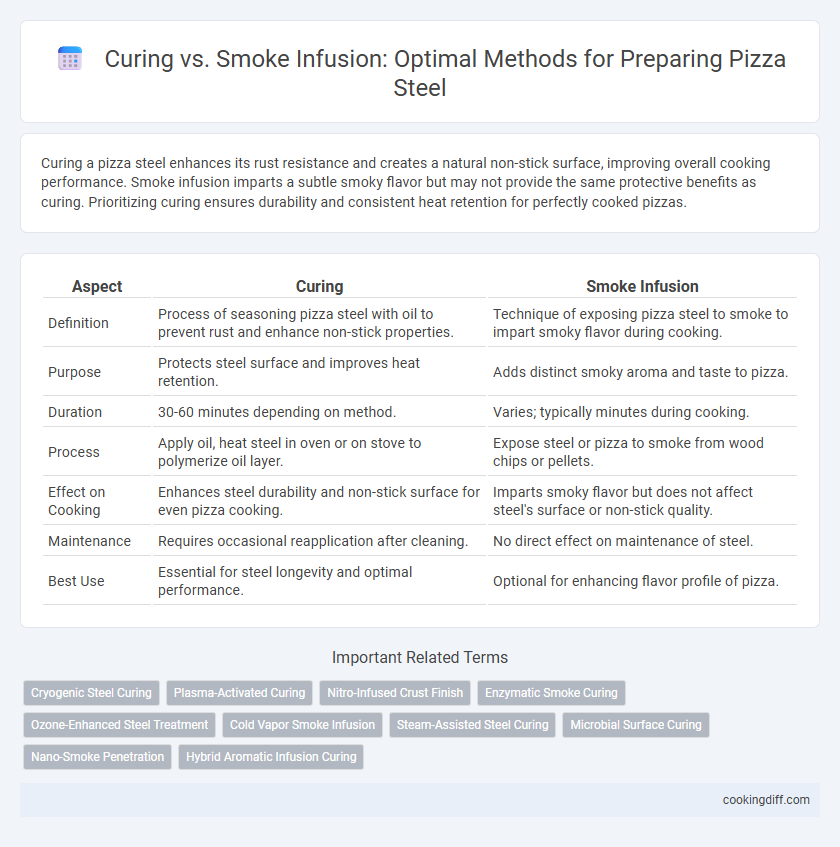

| Aspect | Curing | Smoke Infusion |

|---|---|---|

| Definition | Process of seasoning pizza steel with oil to prevent rust and enhance non-stick properties. | Technique of exposing pizza steel to smoke to impart smoky flavor during cooking. |

| Purpose | Protects steel surface and improves heat retention. | Adds distinct smoky aroma and taste to pizza. |

| Duration | 30-60 minutes depending on method. | Varies; typically minutes during cooking. |

| Process | Apply oil, heat steel in oven or on stove to polymerize oil layer. | Expose steel or pizza to smoke from wood chips or pellets. |

| Effect on Cooking | Enhances steel durability and non-stick surface for even pizza cooking. | Imparts smoky flavor but does not affect steel's surface or non-stick quality. |

| Maintenance | Requires occasional reapplication after cleaning. | No direct effect on maintenance of steel. |

| Best Use | Essential for steel longevity and optimal performance. | Optional for enhancing flavor profile of pizza. |

Understanding Curing and Smoke Infusion Techniques

Curing involves applying oils and heating the pizza steel to create a protective non-stick surface, while smoke infusion imparts a smoky flavor through exposure to wood smoke. Both techniques enhance pizza steel performance but differ in method and flavor impact.

- Curing - Forms a polymerized oil layer that prevents rust and improves non-stick properties.

- Smoke Infusion - Introduces natural smoky aromas by exposing the steel to wood smoke during heating.

- Performance Impact - Curing ensures durability and easy release, while smoke infusion primarily enhances flavor profile.

The Science Behind Curing a Pizza Steel

Curing a pizza steel involves heating it to a high temperature to create a durable, non-stick surface through polymerization of natural oils or seasoning layers. This process enhances thermal conductivity and prevents rust by forming a protective oxide layer on the steel. Unlike smoke infusion, which imparts flavor, curing fundamentally improves the steel's cooking performance and longevity.

Smoke Infusion: Flavor Enhancement or Myth?

| Smoke infusion can impart a subtle smoky aroma to pizza steel, potentially enhancing the flavor of pizzas cooked on it without altering the steel's heat retention properties. |

| Scientific studies show that while smoke particles can adhere to metal surfaces, the flavor enhancement is often minimal compared to direct smoking of food. |

| Many chefs consider smoke infusion on pizza steel more of a marketing myth than a significant flavor enhancer, emphasizing proper curing techniques to maintain steel performance. |

Key Benefits of Properly Cured Pizza Steel

Properly cured pizza steel enhances heat retention and ensures even cooking, resulting in perfectly crispy crusts. Unlike smoke infusion, curing develops a durable, non-stick seasoning that improves with use and resists rust.

- Superior Heat Retention - Well-cured steel stores and distributes heat evenly, preventing hot spots and promoting consistent baking.

- Durable Non-Stick Surface - The curing process creates a robust seasoning layer that reduces sticking and simplifies cleaning.

- Rust Resistance - Proper curing forms a protective barrier that inhibits moisture penetration and extends the steel's lifespan.

Prioritizing curing over smoke infusion ensures optimal performance and longevity of your pizza steel.

Smoke Infusion Methods for Pizza Steel Explained

How does smoke infusion enhance the cooking surface of a pizza steel? Smoke infusion methods involve exposing the pizza steel to flavorful smoke, which penetrates the metal's surface and imparts a distinct aroma and taste to the crust. These techniques not only add complexity to the pizza's flavor but also improve the steel's seasoning, reducing stickiness and promoting even heat distribution.

Comparing Heat Resistance: Cured vs. Smoke-Infused Steels

Curing pizza steel enhances its heat resistance by creating a durable oxide layer that prevents rust and withstands high temperatures without degrading. Smoke-infused steels, while adding flavor elements, generally exhibit lower thermal stability and can break down faster under intense heat.

Cured pizza steels maintain consistent heat distribution essential for achieving optimal pizza crust texture, whereas smoke-infused variants may suffer uneven heating due to altered metal properties. The curing process ensures longevity and resistance to thermal shock, making it preferable for frequent high-heat use. Smoke infusion is best suited for occasional use when flavor enhancement is prioritized over durability and heat performance.

Maintenance and Longevity: Cured vs. Smoke-Infused Pizza Steels

Curing pizza steel creates a protective layer that prevents rust and enhances durability, ensuring long-term maintenance with minimal effort. This process strengthens the steel's surface, making it resistant to moisture and thermal shocks during high-temperature cooking.

Smoke infusion adds flavor but does not provide the same protective benefits as curing, often requiring more frequent maintenance to avoid corrosion. Over time, smoke-infused steels may degrade faster without proper care, reducing their overall longevity compared to cured counterparts.

Impact on Pizza Crust: Texture and Flavor Differences

Curing a pizza steel enhances the crust's texture by creating a non-stick surface that promotes even heat distribution, resulting in a crispier and more uniformly baked crust. The flavor impact is subtle, preserving the natural taste of the dough while preventing sticking and burning.

Smoke infusion introduces a smoky aroma and flavor directly to the crust, adding complexity and a unique taste profile that curing alone cannot achieve. This method may slightly alter the crust texture by imparting a deeper char, enhancing both visual appeal and flavor intensity.

Safety Considerations for Each Technique

Curing pizza steel involves applying oils and heating to create a protective non-stick layer, minimizing rust and contamination risks. Smoke infusion introduces flavor through controlled exposure to smoke but requires careful handling to avoid harmful residues and ensure proper ventilation.

- Curing reduces chemical hazards - Properly cured steel avoids harmful breakdown of surface sealants that can affect food safety.

- Smoke infusion presents respiratory risks - Incomplete smoke combustion can release toxic compounds requiring adequate ventilation.

- Temperature control is critical - Both methods need precise heat management to prevent steel warping or toxic residue formation.

Related Important Terms

Cryogenic Steel Curing

Cryogenic steel curing enhances pizza steel by rapidly cooling the metal, increasing hardness and corrosion resistance without altering its structural integrity, unlike smoke infusion which primarily imparts flavor and surface aroma. This method ensures a durable, low-maintenance cooking surface while maintaining superior thermal conductivity essential for achieving optimal pizza crust texture.

Plasma-Activated Curing

Plasma-Activated Curing utilizes ionized gas to rapidly and uniformly cure pizza steel surfaces, enhancing durability and flavor retention without the greasy residue typical of traditional smoke infusion. This advanced method ensures a cleaner, more precise curing process, improving heat distribution and reducing off-flavors compared to conventional smoking techniques.

Nitro-Infused Crust Finish

Nitro-infused crust finish enhances flavor complexity by rapidly infusing nitrogen into the pizza steel during curing, creating a crisp, airy texture unmatched by traditional smoke infusion. Smoke infusion imparts a classic smoky aroma but lacks the rapid, deep molecular penetration that curing with nitrogen achieves, resulting in a more nuanced and durable crust profile.

Enzymatic Smoke Curing

Enzymatic smoke curing enhances pizza steel by combining natural enzyme activity with smoke infusion, creating a deeply flavored and antibacterial surface that resists rust and improves dough release. Unlike traditional curing, this method targets microbial activity and oxidation, resulting in a longer-lasting, more durable pizza steel with a unique smoky aroma integrated into the metal.

Ozone-Enhanced Steel Treatment

Ozone-enhanced steel treatment significantly accelerates the curing process for pizza steels by eliminating surface impurities and enhancing oxidation resistance without altering flavor profiles. Unlike traditional smoke infusion, this method improves steel durability and hygiene while maintaining optimal thermal conductivity crucial for artisanal pizza baking.

Cold Vapor Smoke Infusion

Cold vapor smoke infusion enhances pizza steel by imparting subtle smoky flavors without heat damage, unlike traditional curing that relies on dry heat or chemical processes. This method preserves the steel's structural integrity while infusing complex aromas, optimizing flavor delivery in artisanal pizza preparation.

Steam-Assisted Steel Curing

Steam-assisted steel curing enhances the durability and heat retention of pizza steels by promoting deep oxidation layers, which surpass traditional smoke infusion methods in preventing rust. This technique produces a uniform, non-toxic coating that improves surface seasoning and thermal conductivity for faster, consistently crisp pizza crusts.

Microbial Surface Curing

Microbial surface curing on pizza steel enhances flavor and shelf-life by promoting beneficial microbial growth that inhibits spoilage organisms, unlike smoke infusion which primarily imparts surface flavor without microbial interaction. This controlled microbial ecosystem during curing supports a natural preservation process, improving dough fermentation and crust texture more effectively than smoke infusion.

Nano-Smoke Penetration

Curing pizza steel enhances durability by creating a protective oxide layer, while smoke infusion leverages nano-smoke penetration to impart deep, flavor-rich characteristics without compromising the steel's heat retention properties. The nano-smoke particles infiltrate microscopic pores on the steel surface, enabling a more intense and enduring smoky flavor that traditional curing alone cannot achieve.

Curing vs Smoke Infusion for Pizza Steel Infographic

cookingdiff.com

cookingdiff.com