A basket deep fryer offers straightforward, quick frying with easy basket lifting for pet treats, ensuring even exposure to hot oil. In contrast, a rotating fryer drum provides continual motion, promoting uniform cooking and reducing oil absorption for healthier results. Choosing between basket and rotating drum depends on desired texture and efficiency in deep-frying pet foods.

Table of Comparison

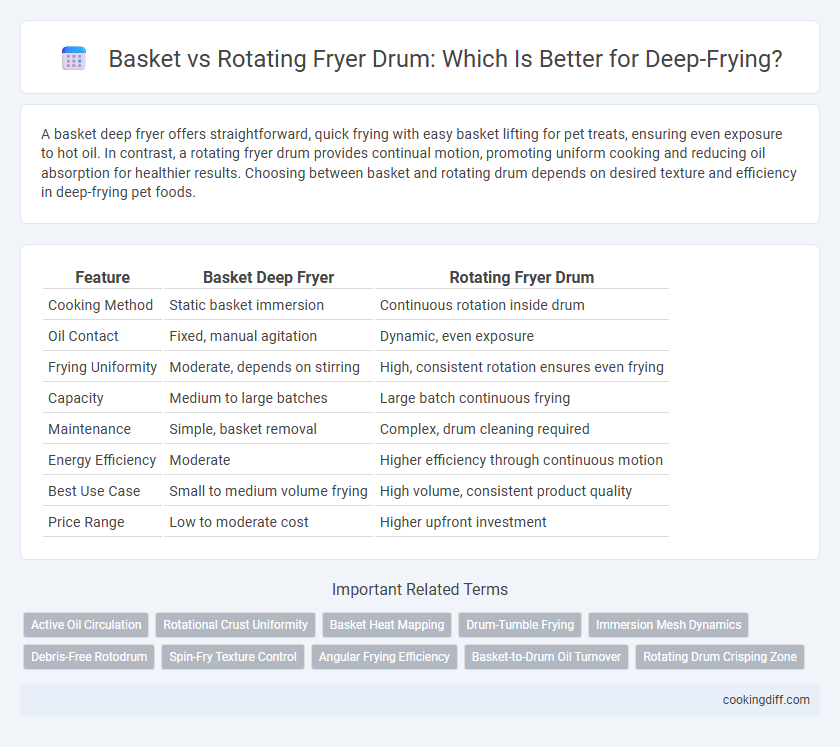

| Feature | Basket Deep Fryer | Rotating Fryer Drum |

|---|---|---|

| Cooking Method | Static basket immersion | Continuous rotation inside drum |

| Oil Contact | Fixed, manual agitation | Dynamic, even exposure |

| Frying Uniformity | Moderate, depends on stirring | High, consistent rotation ensures even frying |

| Capacity | Medium to large batches | Large batch continuous frying |

| Maintenance | Simple, basket removal | Complex, drum cleaning required |

| Energy Efficiency | Moderate | Higher efficiency through continuous motion |

| Best Use Case | Small to medium volume frying | High volume, consistent product quality |

| Price Range | Low to moderate cost | Higher upfront investment |

Introduction: Basket vs Rotating Fryer Drum

Deep-frying techniques vary significantly between basket fryers and rotating fryer drums, each offering unique advantages for cooking consistency and efficiency. Selecting the appropriate frying method impacts oil absorption and product crispness.

- Basket Fryer - Utilizes a removable wire basket to lower and lift food into hot oil, allowing quick draining and easy handling.

- Rotating Fryer Drum - Features a rotating drum that tumbles food in hot oil, ensuring even cooking and reducing oil retention.

- Efficiency and Quality - Basket fryers are preferred for batch frying with high throughput, while rotating drums enhance uniformity for irregularly shaped foods.

How Basket Fryers Work

Basket fryers operate by submerging a wire mesh basket loaded with food into a vat of hot oil, allowing for even cooking through direct oil contact. The basket design enables quick removal and draining of excess oil, enhancing food crispiness and reducing grease retention.

The mesh construction of the basket promotes efficient oil circulation around the food, preventing sogginess and ensuring consistent frying temperatures. Operators can easily lift and shake the basket to separate fried items, improving texture and minimizing clumping during the cooking process.

How Rotating Fryer Drums Operate

Rotating fryer drums operate by continuously tumbling food items within a cylindrical mesh or perforated drum submerged in hot oil, ensuring even cooking and browning. This motion prevents sticking and promotes uniform heat exposure, reducing frying time and improving texture consistency. The design also enhances oil filtration by allowing debris to fall through the drum, maintaining oil quality during extended use.

Advantages of Basket Deep Fryers

Basket deep fryers offer superior control over cooking time and temperature, ensuring evenly fried food with a crispy texture. Their removable baskets facilitate easy handling and quick draining of excess oil, improving food quality and safety. These fryers are ideal for smaller batches, providing flexibility and energy efficiency which is beneficial in both commercial and home kitchens.

Benefits of Rotating Fryer Drum Systems

Rotating fryer drum systems provide uniform heat distribution, resulting in consistent cooking quality and reduced oil absorption. This method enhances product texture and color, making it ideal for high-volume food production.

These systems increase frying efficiency by continuously agitating food, which prevents sticking and allows for faster cooking times compared to traditional basket fryers. The rotating mechanism promotes even oil exposure, reducing hot spots and minimizing product degradation. Maintenance is simplified due to fewer build-ups of food particles, extending the life of frying oil and equipment.

Oil Circulation and Food Crispiness

Basket deep-fryers promote intense oil circulation by agitating food through submersion and basket shaking, resulting in evenly crisped surfaces. The turbulence created by the basket motion enhances heat transfer, preserving food texture and moisture.

Rotating fryer drums offer continuous, gentle rotation that maintains consistent oil flow and temperature distribution around all food pieces. This controlled movement reduces oil absorption while achieving uniform crispiness across large batches, ideal for high-volume frying operations.

Ease of Cleaning and Maintenance

| Basket Deep-Fryer | Features a removable basket that simplifies cleaning by allowing oil drainage and direct access to all surfaces, reducing residue buildup and maintenance time. |

| Rotating Fryer Drum | Contains internal components that require disassembly for thorough cleaning, often leading to longer maintenance periods and increased labor compared to basket fryers. |

Cooking Capacity and Efficiency Comparison

Which offers better cooking capacity and efficiency: a basket or a rotating fryer drum for deep-frying? Basket fryers typically allow for larger batch sizes but may result in uneven cooking due to oil circulation limitations. Rotating fryer drums enhance oil flow and heat distribution, improving cooking uniformity and reducing frying time for similar capacities.

Safety Considerations for Both Fryer Types

Basket fryers generally require manual handling, increasing the risk of hot oil splashes and burns during basket removal. Rotating fryer drums provide automated movement, reducing direct contact with hot oil and enhancing operator safety.

- Basket fryers demand careful manual lifting - Operators must use protective gear to prevent burns from hot oil splatter.

- Rotating drums minimize manual intervention - Automated rotation decreases exposure to hot oil, lowering injury risks.

- Both fryer types require regular maintenance - Ensuring safety features like thermal cutoffs and emergency stops function correctly is critical.

Choosing between basket and rotating drum fryers involves balancing operational safety with handling preferences to mitigate deep-frying hazards effectively.

Related Important Terms

Active Oil Circulation

Active oil circulation in deep-frying significantly enhances heat transfer and oil filtration efficiency, with rotating fryer drums offering superior continuous oil movement compared to static baskets. This results in even cooking, reduced oil degradation, and improved food quality during high-volume frying operations.

Rotational Crust Uniformity

Rotating fryer drums ensure enhanced rotational crust uniformity by continuously turning food items, which promotes even exposure to hot oil and consistent browning on all surfaces. This dynamic motion reduces hotspots and minimizes oil absorption compared to static basket frying, resulting in a uniformly crispy texture and improved product quality.

Basket Heat Mapping

Basket heat mapping in deep-frying reveals uneven temperature distribution, causing localized hotspots that can lead to inconsistent cooking and oil degradation, while rotating fryer drums ensure more uniform heat exposure by continuously tumbling the food, resulting in even crispiness and improved oil life. Precise thermal mapping highlights the advantage of rotating drums in maintaining consistent frying temperatures across all food surfaces, optimizing both product quality and operational efficiency.

Drum-Tumble Frying

Drum-tumble frying in rotating fryer drums ensures even heat distribution and consistent crispiness by continuously agitating food, minimizing oil absorption compared to static basket frying. This method optimizes cooking efficiency and texture quality, especially for irregularly shaped or delicate items.

Immersion Mesh Dynamics

Basket fryers provide consistent immersion mesh dynamics by suspending food items in a stationary mesh, ensuring even oil contact and heat transfer, ideal for uniform cooking of irregularly shaped products. Rotating fryer drums enhance immersion mesh dynamics through continuous movement, promoting agitation of oil and food interchange, reducing frying time and improving crispness by minimizing oil absorption.

Debris-Free Rotodrum

The rotating fryer drum offers a debris-free deep-frying experience by continuously agitating food, preventing particles from settling and accumulating compared to traditional basket frying. This not only ensures cleaner oil but also enhances the consistency and quality of the fried products.

Spin-Fry Texture Control

The rotating fryer drum offers superior spin-fry texture control by evenly tumbling food, ensuring uniform crispiness and reduced oil absorption compared to traditional basket deep-frying. This technology enhances surface browning and moisture retention, delivering consistently crunchy results ideal for products like fries and chicken wings.

Angular Frying Efficiency

Basket fryers provide consistent angular frying efficiency by maintaining uniform oil circulation around food items, whereas rotating fryer drums enhance angular heat distribution through continuous drum rotation, leading to more even cooking and reduced oil absorption. The rotating drum's dynamic movement minimizes stagnant oil zones, optimizing heat transfer angles for superior frying performance compared to static baskets.

Basket-to-Drum Oil Turnover

A rotating fryer drum typically achieves higher basket-to-drum oil turnover rates compared to traditional basket fryers, enhancing heat transfer and reducing oil degradation. This improved circulation promotes consistent cooking temperatures and extends oil life, resulting in better product quality and lower maintenance costs.

Basket vs Rotating fryer drum for deep-frying. Infographic

cookingdiff.com

cookingdiff.com