Conventional oil filters rely on manual or pump-driven systems that can be time-consuming and less effective in removing fine particles from deep-frying oil, leading to quicker oil degradation and off-flavors in fried pet food. Gravity oil filtration systems use the natural force of gravity to gently filter oil through fine mesh or paper filters, preserving oil quality longer by efficiently removing debris and minimizing oxidation. This results in improved flavor retention and extended oil life, making gravity filtration a superior choice for maintaining optimal frying conditions in pet food preparation.

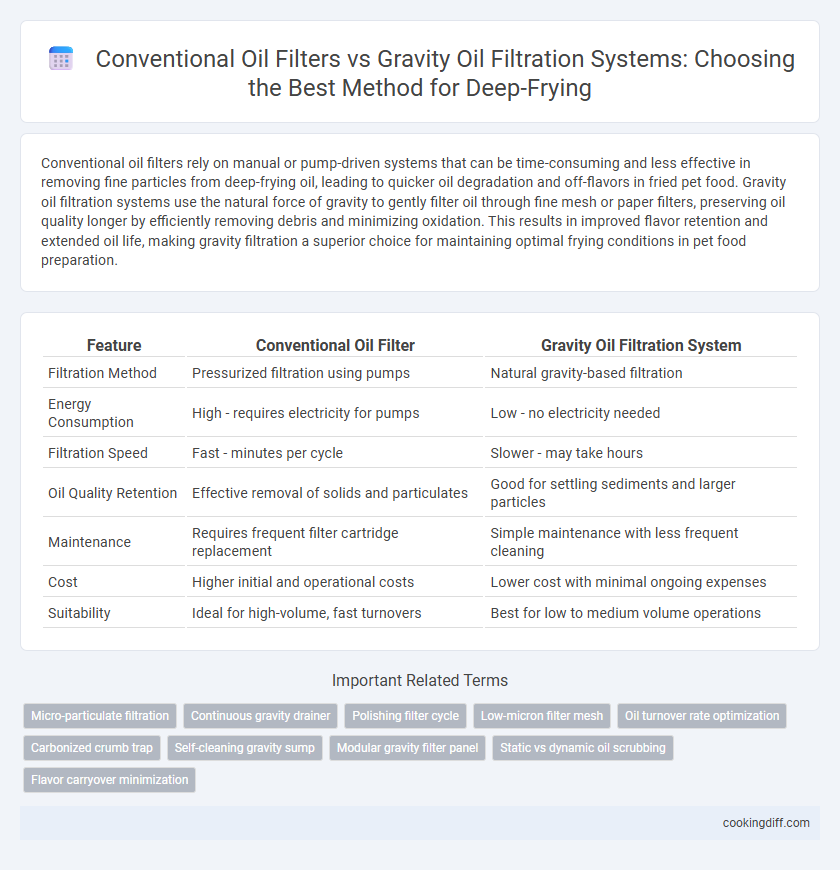

Table of Comparison

| Feature | Conventional Oil Filter | Gravity Oil Filtration System |

|---|---|---|

| Filtration Method | Pressurized filtration using pumps | Natural gravity-based filtration |

| Energy Consumption | High - requires electricity for pumps | Low - no electricity needed |

| Filtration Speed | Fast - minutes per cycle | Slower - may take hours |

| Oil Quality Retention | Effective removal of solids and particulates | Good for settling sediments and larger particles |

| Maintenance | Requires frequent filter cartridge replacement | Simple maintenance with less frequent cleaning |

| Cost | Higher initial and operational costs | Lower cost with minimal ongoing expenses |

| Suitability | Ideal for high-volume, fast turnovers | Best for low to medium volume operations |

Introduction to Deep-Frying Oil Filtration

How does the choice between conventional oil filters and gravity oil filtration systems impact deep-frying oil quality? Conventional oil filters use pressure to force oil through filter media, effectively removing larger food particles and extending oil usability. Gravity oil filtration systems rely on natural sedimentation, offering a gentler filtration process that preserves oil freshness and reduces oxidation during deep-frying.

Why Oil Filtration Matters in Deep-Frying

Efficient oil filtration extends the life of frying oil by removing food particles and contaminants that accelerate oil degradation. Conventional oil filters often require manual operation and may not remove fine particulates as effectively as gravity oil filtration systems, which use natural settling to clarify oil gently and continuously.

- Oil Quality Preservation - Gravity filtration systems maintain oil quality longer by reducing thermal and oxidative stress compared to conventional filters.

- Operational Efficiency - Conventional oil filters typically involve labor-intensive cleaning processes, whereas gravity systems operate with minimal intervention.

- Cost Effectiveness - Gravity filtration reduces oil replacement frequency, lowering overall frying costs and minimizing waste.

Choosing the appropriate filtration system directly impacts the taste, safety, and cost-efficiency of deep-fried products.

What Is a Conventional Oil Filter?

| Conventional oil filters in deep-frying typically use a paper or mesh element to trap food particles and contaminants, maintaining oil clarity and quality during multiple frying cycles. |

| These filters require manual installation and frequent replacement to prevent clogging and ensure optimal performance, which can increase operational downtime in commercial kitchens. |

| Compared to gravity oil filtration systems, conventional filters offer quicker filtration but may be less efficient at removing fine impurities and do not extend oil life as effectively. |

How Gravity Oil Filtration Systems Work

Conventional oil filters rely on mechanical pressure to force oil through a filter medium, capturing food particles and debris during deep-frying. Gravity oil filtration systems utilize natural gravitational force to slowly drain and filter oil, reducing agitation and preserving oil quality.

Gravity oil filtration systems work by positioning the used frying oil above a fine-mesh or paper filter, allowing contaminants to settle and separate as the oil flows downward due to gravity. This method minimizes exposure to air and heat, helping extend the frying oil's usable life. By gently filtering impurities without mechanical stress, gravity systems maintain oil clarity and flavor more effectively than conventional pressure-based filters.

Key Differences: Conventional vs Gravity Filtration

Conventional oil filters use pressure and mechanical components to rapidly remove food particles and impurities from deep-frying oil, ensuring quick filtration. Gravity oil filtration systems rely on natural sedimentation, allowing particles to settle at the bottom over time without mechanical force, which results in slower but gentler oil cleaning. The key difference lies in filtration speed and complexity, with conventional filters offering faster processing and gravity systems providing low-maintenance, energy-efficient operation.

Performance Comparison: Oil Clarity & Food Quality

Conventional oil filters often leave more particulate matter in the oil, resulting in reduced oil clarity and potential off-flavors in fried foods. Gravity oil filtration systems utilize natural sedimentation, providing superior oil clarity that enhances food quality with fewer impurities retained.

- Oil Clarity - Gravity systems offer clearer oil by allowing suspended particles to settle naturally compared to conventional filters that may trap smaller debris inefficiently.

- Food Quality - Foods fried in oil filtered through gravity systems have a fresher taste and better texture due to lower levels of degraded oil compounds.

- Filter Maintenance - Gravity filtration requires less frequent intervention, maintaining consistent oil quality over a longer frying period.

Cost Analysis: Initial Investment and Maintenance

The initial investment for a conventional oil filter system in deep-frying is generally lower, making it accessible for small to medium-sized operations. However, frequent replacement of filter media and labor costs for manual filtration increase long-term expenses.

Gravity oil filtration systems require a higher upfront cost due to advanced equipment and automation features, but they reduce ongoing maintenance and labor costs by efficiently removing oil contaminants. Over time, gravity filtration can extend oil life and improve operational cost-efficiency in high-volume frying operations.

Operational Efficiency and Downtime

Conventional oil filters require frequent manual intervention, causing longer downtime during deep-frying operations. Gravity oil filtration systems operate continuously with minimal human input, significantly enhancing operational efficiency. Reduced filtration downtime leads to extended oil life and consistent frying quality in commercial kitchens.

Sustainability and Oil Lifespan

Gravity oil filtration systems enhance sustainability by reducing the frequency of oil changes, thus minimizing waste generation compared to conventional oil filters. Extending oil lifespan through gentle removal of food particles and impurities conserves resources and lowers operational costs in deep-frying operations.

- Lower Oil Degradation - Gravity filtration gently removes contaminants without overheating the oil, preserving its chemical integrity longer than conventional filters.

- Reduced Environmental Impact - Fewer oil replacements decrease hazardous waste production and the energy consumption tied to oil manufacturing and disposal.

- Cost-Effectiveness - Prolonged oil usability results in reduced purchasing frequency, contributing to sustainable economic benefits for commercial kitchens.

Related Important Terms

Micro-particulate filtration

Conventional oil filters use pressure-driven systems to remove larger food particles from frying oil, but often miss fine micro-particulates that degrade oil quality and flavor. Gravity oil filtration systems excel at micro-particulate filtration by allowing suspended fine particles to settle naturally, resulting in cleaner oil and extended frying cycle life.

Continuous gravity drainer

Continuous gravity drainer systems for deep-frying offer superior efficiency by allowing oil to flow naturally through filtration media, removing food particles without interrupting frying operations. Unlike conventional oil filters that require downtime and mechanical pumping, gravity-driven filtration maintains oil quality in real-time, prolonging oil life and enhancing frying consistency.

Polishing filter cycle

Conventional oil filters require frequent manual intervention during the polishing filter cycle, leading to intermittent filtration and potential downtime. Gravity oil filtration systems offer continuous polishing by allowing oil to pass through filter media using natural gravitational force, enhancing oil clarity and extending frying oil life with minimal operational disruption.

Low-micron filter mesh

Low-micron filter mesh in gravity oil filtration systems effectively removes fine particles and impurities, enhancing oil clarity and extending its usable life compared to conventional oil filters with larger mesh sizes. This precise filtration reduces oil degradation and maintains consistent frying quality, optimizing overall kitchen efficiency and food safety.

Oil turnover rate optimization

Gravity oil filtration systems optimize oil turnover rate by allowing continuous sediment separation through natural settling, resulting in prolonged oil life and improved food quality compared to conventional oil filters that require frequent manual intervention and have limited filtration capacity. This enhanced turnover rate reduces oil degradation and minimizes fryer downtime, increasing operational efficiency in commercial deep-frying environments.

Carbonized crumb trap

Conventional oil filters rely on fine mesh screens that often miss carbonized crumbs, leading to faster oil degradation in deep-frying. Gravity oil filtration systems effectively trap carbonized residues through sedimentation, extending oil life and improving fryer performance.

Self-cleaning gravity sump

The self-cleaning gravity sump in gravity oil filtration systems offers continuous removal of food particles and sediment during deep-frying, enhancing oil clarity and extending its usable life compared to conventional oil filters that require frequent manual replacement or cleaning. This system reduces maintenance downtime and improves frying quality by maintaining optimal oil conditions through efficient, automatic sediment separation.

Modular gravity filter panel

The modular gravity filter panel in gravity oil filtration systems offers efficient removal of food particles and impurities from deep-frying oil, extending oil life and enhancing food quality compared to conventional oil filters. Its scalable design allows for easy integration and maintenance, reducing downtime and operational costs in high-volume frying applications.

Static vs dynamic oil scrubbing

Conventional oil filters use static oil scrubbing that traps particles through a stationary filter medium, often requiring frequent cleaning to maintain efficiency, while gravity oil filtration systems employ dynamic oil scrubbing by allowing oil to flow continuously through gravity-driven filtration, enhancing debris removal and extending oil life during deep-frying. Dynamic gravity filtration reduces sediment build-up and maintains oil quality longer compared to the static approach in conventional filters, improving food taste and frying performance.

Conventional oil filter vs gravity oil filtration system for deep-frying. Infographic

cookingdiff.com

cookingdiff.com