Deep-frying uses hot oil to transfer heat rapidly, resulting in crispy textures and rich flavors, while infrared-frying relies on infrared radiation to cook food with minimal or no oil, offering a healthier alternative. Infrared-frying provides more even heat distribution and reduces oil absorption compared to traditional deep-frying, enhancing nutritional value and lowering fat content. Consumers seeking a balance between taste and health benefits often prefer infrared-frying for its energy efficiency and reduced risk of harmful compounds formed during deep-frying.

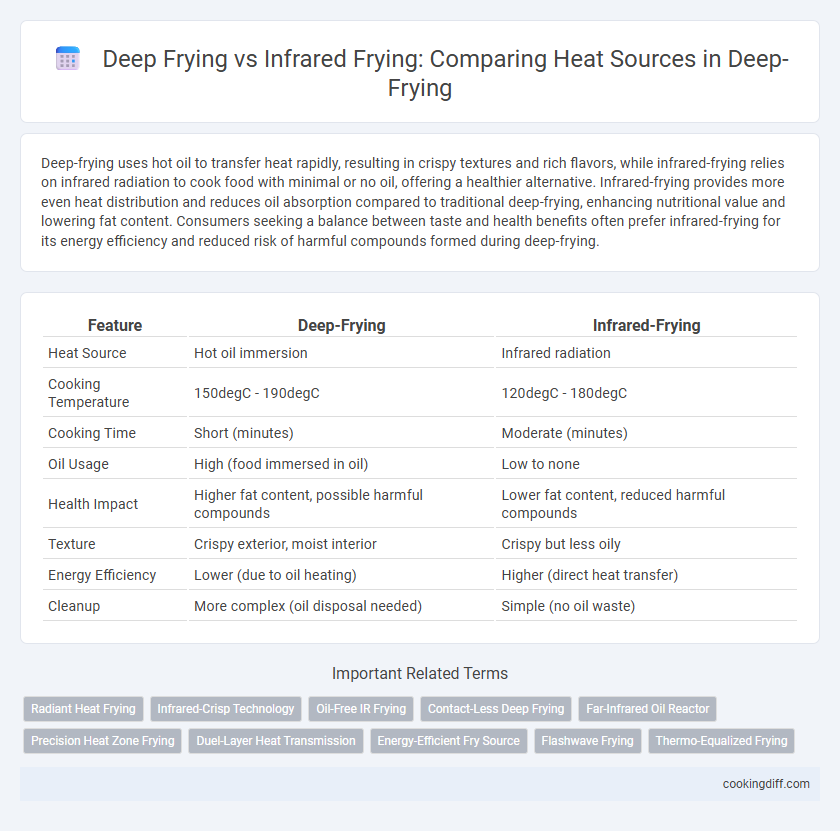

Table of Comparison

| Feature | Deep-Frying | Infrared-Frying |

|---|---|---|

| Heat Source | Hot oil immersion | Infrared radiation |

| Cooking Temperature | 150degC - 190degC | 120degC - 180degC |

| Cooking Time | Short (minutes) | Moderate (minutes) |

| Oil Usage | High (food immersed in oil) | Low to none |

| Health Impact | Higher fat content, possible harmful compounds | Lower fat content, reduced harmful compounds |

| Texture | Crispy exterior, moist interior | Crispy but less oily |

| Energy Efficiency | Lower (due to oil heating) | Higher (direct heat transfer) |

| Cleanup | More complex (oil disposal needed) | Simple (no oil waste) |

Introduction to Deep-frying and Infrared-frying

Deep-frying uses hot oil to cook food rapidly, creating a crispy texture through immersion in heated oil typically between 160-190degC. Infrared-frying employs infrared radiation as the heat source, offering a non-contact cooking method that can reduce oil usage and improve cooking efficiency.

- Deep-frying heat transfer - Primarily relies on convection heat transfer from hot oil surrounding the food.

- Infrared-frying heat transfer - Utilizes radiant heat waves that directly penetrate the food surface, cooking it evenly.

- Oil consumption - Deep-frying requires large quantities of oil, while infrared-frying significantly decreases oil usage for a healthier alternative.

How Deep-frying Works: Heat Transfer and Oil

Deep-frying uses hot oil to transfer heat rapidly to food, cooking it quickly and creating a crispy texture. Infrared-frying, however, relies on radiant heat without submerging food in oil, resulting in different heat transfer dynamics.

- Heat Transfer Efficiency - Deep-frying provides uniform heat distribution due to oil's high thermal conductivity.

- Oil Absorption - Food absorbs oil during deep-frying, contributing to flavor and texture changes.

- Surface Interaction - Infrared-frying heats the food surface directly, reducing oil exposure and potential greasiness.

Understanding the differences in heat transfer and oil interaction helps optimize cooking methods for desired food quality.

Understanding Infrared-frying: Technology and Process

| Heat Source | Infrared-frying uses infrared radiation to transfer heat directly to food, while deep-frying relies on hot oil immersion for heat transfer. |

| Technology | Infrared-frying employs infrared emitters that produce radiant heat, enhancing energy efficiency and reducing oil absorption compared to conventional deep-frying. |

| Process | Infrared-frying cooks food by exposing it to an optimized wavelength range of infrared rays, enabling faster heat penetration and uniform cooking without submerging food in oil. |

Cooking Performance: Speed and Evenness

Deep-frying cooks food rapidly due to the high and consistent temperature of hot oil, ensuring fast heat transfer and crispy results. Infrared-frying uses radiant heat, which can provide more even cooking without direct contact with oil, but it may cook slower than traditional deep-frying. The evenness of infrared-frying reduces hotspots and overcooked areas, improving overall texture without compromising cooking speed significantly.

Oil Usage and Health Considerations

How do oil usage and health considerations compare between deep-frying and infrared-frying? Deep-frying typically requires large volumes of oil, leading to higher fat content and increased calorie intake, while infrared-frying uses significantly less oil, resulting in lower fat absorption. Infrared-frying also reduces the formation of harmful compounds like acrylamide, making it a healthier alternative to traditional deep-frying methods.

Flavor and Texture Differences

Deep-frying uses hot oil to create a crispy texture and rich flavor through Maillard reactions, resulting in a golden-brown crust and moist interior. Infrared-frying employs infrared radiation to cook food evenly, producing a less oily texture but with milder flavor intensity.

Deep-frying imparts a distinct savory taste and crunchy texture due to oil absorption and high heat contact, enhancing food's sensory appeal. Infrared-frying reduces fat content while maintaining tenderness but may lack the deep, complex flavors achieved by traditional deep-frying. Texture differences are notable, with infrared-fried items being less greasy and slightly firmer compared to the richly fried counterparts.

Energy Efficiency Comparison

Deep-frying relies on oil as a heat transfer medium, requiring higher temperatures and longer cooking times, which results in greater energy consumption. Infrared-frying uses infrared radiation to directly heat food surfaces, significantly reducing energy loss and improving overall energy efficiency.

Studies show infrared-frying can reduce energy usage by up to 30% compared to traditional deep-frying methods. This efficiency gain stems from faster heat penetration and more precise temperature control, leading to lower operational costs and environmental impact.

Safety Aspects of Both Methods

Deep-frying involves submerging food in hot oil, creating risks of burns and oil fires due to high temperatures and splattering. Infrared-frying uses radiant heat to cook food with minimal oil, significantly reducing fire hazards and lowering the risk of hot oil burns.

- Fire Hazard - Deep-frying carries a higher risk of oil ignition compared to infrared-frying, which uses safer radiant heat without large quantities of oil.

- Burn Risk - Hot oil exposure in deep-frying increases chances of severe burns, whereas infrared-frying minimizes contact with heated liquids.

- Ventilation and Fumes - Deep-frying produces more smoke and harmful fumes requiring effective ventilation, while infrared-frying generates fewer airborne contaminants enhancing kitchen safety.

Maintenance and Cleanup

Deep-frying requires regular oil filtration and frequent oil changes to prevent residue buildup that can affect flavor and safety. Maintenance involves cleaning fryers thoroughly to remove grease and carbon deposits, which can be time-consuming and labor-intensive.

Infrared-frying generates less oil splatter due to controlled heat application, leading to easier and faster cleanup processes. The absence of direct oil immersion reduces the need for frequent equipment maintenance and extends the lifespan of heating elements.

Related Important Terms

Radiant Heat Frying

Radiant heat frying, as utilized in infrared-frying, offers precise temperature control and reduced oil absorption compared to traditional deep-frying, enhancing food texture and nutritional value. Infrared-frying heats food through radiant energy, ensuring even cooking and faster heat penetration, which minimizes oil breakdown and the formation of harmful compounds.

Infrared-Crisp Technology

Infrared-Crisp Technology harnesses infrared radiation to deliver rapid, even heat distribution, reducing oil usage compared to traditional deep-frying and resulting in a crispier texture with lower fat content. This technology enhances energy efficiency and maintains food quality by minimizing heat degradation and moisture loss during frying.

Oil-Free IR Frying

Oil-free infrared frying uses infrared radiation as a heat source to cook food without submerging it in oil, reducing oil absorption and producing lower-calorie, healthier results compared to traditional deep-frying. Infrared technology enables rapid and even heat distribution, resulting in crispy textures similar to deep-frying but with significantly less fat and fewer harmful compounds.

Contact-Less Deep Frying

Infrared-frying offers a contact-less deep-frying method by using infrared radiation to heat food evenly without direct oil immersion, reducing oil absorption and enhancing crispiness. This technique maintains high temperatures similar to traditional deep-frying, ensuring efficient heat transfer while promoting healthier cooking with less oil residue.

Far-Infrared Oil Reactor

Deep-frying traditionally relies on hot oil at temperatures typically between 160degC and 190degC, providing efficient heat transfer through convection and immersion. In contrast, the Far-Infrared Oil Reactor uses far-infrared radiation to uniformly heat oil molecules, enhancing energy efficiency and reducing oil degradation while maintaining crispy textures in fried foods.

Precision Heat Zone Frying

Precision Heat Zone Frying in deep-frying offers targeted temperature control by immersing food in hot oil, ensuring uniform heat distribution and optimal crispiness. Infrared-frying utilizes radiant heat for surface cooking but lacks the precise, consistent heat zones critical for achieving the even texture and thorough cooking characteristic of traditional deep-frying.

Duel-Layer Heat Transmission

Deep-frying utilizes direct oil immersion, providing efficient heat transfer through convection and conduction, resulting in rapid and uniform cooking with a crispy texture. Infrared-frying employs dual-layer heat transmission combining infrared radiation and surface conduction, enhancing energy efficiency and reducing oil absorption while maintaining similar crispiness.

Energy-Efficient Fry Source

Infrared-frying offers a more energy-efficient heat source for deep-frying by using radiant heat that penetrates food quickly, reducing cooking time and overall energy consumption compared to traditional oil-based deep-frying methods. This method minimizes heat loss and lowers oil usage while maintaining crispy texture and flavor, making infrared-frying a sustainable alternative for high-volume frying operations.

Flashwave Frying

Flashwave frying uses infrared radiation to rapidly heat food surfaces, reducing oil absorption compared to traditional deep-frying methods that immerse foods in hot oil. This infrared-based Flashwave technique enhances energy efficiency and produces crisp textures with lower fat content, appealing to health-conscious consumers and commercial kitchens aiming for cleaner frying processes.

Deep-frying vs Infrared-frying for heat source. Infographic

cookingdiff.com

cookingdiff.com